Palliative Medicine & Care - Juniper Publishers

Background and purpose: A single-center

observational study involved the assessment of pain in palliative care

patients PC who required surgery. The question was asked: How does acute

pain influence the behavioral pain perception in palliative patients

treated with opioid drugs before and after surgery.

Materials and methods: Patients who were

qualified for surgical procedure and diagnosed with a disease qualifying

for palliative treatment were followed up. Acute pain therapy was

applied in the ward as in all cardiac surgeries. The diagnosis in the

applied pain therapy was not distinguished due to the coexisting

palliative disease. All patients received pain medication according to

the same schedule. The survey assessed the level of pain sensation and

the accompanying emotional states such as anxiety, fear and depression.

The standardized and own type questionaries’ has been used.

Results: Based on the analysis of the answers

provided, 30% of respondents PC rated their pain, assessed on the 4th

day at 7/10, i.e. severe. More than half of the respondents replied that

they had new pain ailments. Patients indicated more than one location

of the intensity of postoperative pain, but the highest intensity of

pain was found at the operated site. The patients indicated the

occurrence of anxiety and there was no difference between the anxiety

before and after the surgery. When expressed about pain, it can be seen

that the elderly complained less about pain than younger people.

Discussion: The conducted studies of

behavioural pain assessment in cardiac surgery patients indicate that

the overall health condition of the patient should be taken into account

in the assessment of pain. It has been shown that patients who have had

palliative disease are prone to pain after cardiac surgery procedures

and that conventional pain treatment in these patients is not

sufficient. Analysis of the collected data provided information on the

use of painkillers, pain assessment and how patients cope with emotions

after surgery during palliative treatment. The choice of painkillers

depends primarily on: the type of pain, its severity, as well as the

length of pharmacotherapy and whether the previous analgesic therapy and

the drugs used reduced the pain.

Palliative patients are a group particularly exposed

to pain. Post-operative pain in this condition caused by damage to

tissues, intensified by perioperative stress, causes an additional

emotional and behavioural response of the system to surgical actions

[1]. Regardless of the primary disease, pain after cardiac surgery, and

in particular after midline sternotomy, is a strong, critically related

to proper ventilation and haemostasis of the circulatory

system. Acute pain caused by surgery forces an unfavorable position,

which is difficult for the proper respiratory mechanics, leads to

atelectasis, worsening of postoperative complications and changes in the

perception of pain stimuli, including persistent chronic pain [2].

According to the literature data, properly treated patients without

additional comorbidities stop experiencing acute pain a few days after

the procedure. On the other hand, the lack of adequate pain treatment

after surgery may cause pain to persist for many months after the

patient’s discharge [3]. Palliative

patients operating in cardiac surgery departments constitute

a special, diverse group of patients. Most often, operations are

performed on them because of the primary palliative disease

or diseases that occurred during palliative treatment. They are

in each of these cases particularly prone to pain and are usually

treated with anti-pain medications before surgery; therefore,

postoperative pain perception may be different in this group of

patients. Additional acute pain, insufficiently controlled, has an

impact on the partial and / or complete disability of the patient.

It is a problem that, if it occurs, will intensify the occurrence of

chronic and persistent pain, which causes escalation of the doses

of anti-pain medications and limiting the independence and

comfort of life [3,4].

The choice of the drug, as well as its dosage, depends on the

intensity of pain and is based on the use of analgesics of increasing

effectiveness, as well as supplementing the action of analgesics [5].

According to WHO recommendations, drugs are used in palliative

patients according to the analgesic ladder [6]. The first step of

the analgesic ladder covers the treatment of low intensity pain

on the numerical scale (NRS). In such cases, it is recommended

to use non-opioid analgesics (NSPB), which include non-steroidal

anti-inflammatory drugs (NSAIDs) as well as paracetamol

and metamizole. NSAIDs have an analgesic effect, especially

in nociceptive pain. They are more effective than paracetamol

and metamizole in counteracting inflammatory pain. In order

to improve the effectiveness of analgesia, it is recommended to

combine NSAIDs with paracetamol, but never to combine two

NSAIDs, as well as paracetamol and metamizole, because they act

on similar cyclooxygenase isoforms. NLPB should be administered

in doses and at intervals that guarantee effective analgesia. In the

case of NSAIDs, the choice of dose and timing of administration is

dependent on the drug selected. On the other hand, paracetamol

is used in regular 4-6 hour intervals. In the case of NSAIDs, it is

worth remembering that drugs have their effect on the activity of

COX-1 and COX-2, which may cause differences in the profile of

their analgesic effects and the profile of side effects [7].

The second step of the WHO analgesic ladder covers the

treatment of pain with a severity of> 4-6. The transition from

the 1st to the 2nd and 3nd step of the ladder occurs most often due

to the ineffectiveness of drugs in the 1st step of the ladder or in

the case of increasing pain associated with the disease [8]. In the

case of using tramadol, it should be remembered that due to the

serotoninergic mechanism of action of these drugs, they should

not be combined with other drugs enhancing the transmission

of serotoninergic system due to the risk of serotonin syndrome.

Drugs from the 2nd rung of the analgesic ladder should not be

combined [9].

After surgery, pain often reduces the patient’s satisfaction with

the procedure performed. Pain delays the patient’s mobilization,

increases the incidence of postoperative complications and

increases mortality [10]. In patients staying in the postoperative

ward, it can cause depression and excessive excitability, fear, and

fear of their own health in the future [10]. It is believed that the

emotions accompanying the patient have an evident influence on

the perception of pain [11]. Patients with additional anxiety and

fear experience worse postoperative pain [11].

In the preparatory management of postoperative pain,

the general assumptions, recommendations for education and

planning of perioperative management in pain therapy after

cardiac surgery should be taken into account. It is important that

the patient is provided with knowledge about the possibilities

of pain treatment [12]. The psychological sensations of a pain

stimulus consist of closely related stages. The first stage is

sensory-discriminatory experience, while the second stage

causes a reaction of pain with a small share of other functions. In

the first two stages, it is possible to assess using pain scales such

as VAS or NRS. The next stage is the suffering stage, it is related

to the patient’s feelings and views on pain [9]. The final stage is

behavioral pain expression, also known as conservative pain. This

stage determines the patient’s motor activities. The evaluation of

the emotions of anxiety and fear of the second stage was carried

out on the basis of the answers to the questions included in the

survey.

The study posed the question: is pain sufficiently measured

in palliative patients if they are treated according to the regimen

typical for patients without palliative disease? Does pain depend

on the presence of pre-operative anxiety and depression in

postoperative patients? In addition, it was decided to investigate

whether the type of pain ailments changes the expression of

emotions such as fear, anxiety, anxiety in these patients, and the

quality of analgesia was assessed, allowing for the performance

of respiratory therapy and other physiotherapeutic procedures.

The method of diagnostic survey was used in the study. The

survey was conducted anonymously. It was carried out among

patients staying in the postoperative ward of the Cardiac Surgery

Clinic of the University Teaching Hospital in Białystok. The study

involved 50 patients. The study included patients who were on

day 4 after surgery. The study included patients with diseases

eligible for elective surgery and who were treated palliatively

prior to surgery. The research tool was a questionnaire containing

questions, as well as elements of the VAS, NRS, PHHPS scale, and

questions related to the coexistence of emotions such as anxiety,

depression.

The survey was divided into two parts. The first part is sociogeographic

questions, while the second is specific questions

about pain assessment. The questions contained in it concerned

the patient’s well-being and the assessment of the severity of

pain after cardiac surgery. The respondents were informed about the purpose and scope of the study and were presented with a

consent form to participate in the study. Patients who were aware,

in logical verbal contact, were treated on an outpatient basis and

in hospital after procedures such as:

a) Patients undergoing cardiac surgery without circulation

b) Patients after operations in extracorporeal circulation

not longer than 3 hours

c) Postoperative pain measurement was based on features

such as pain intensity, duration and location.

d) Pain was assessed using the VAS and NRS scales.

VAS (Visual Analogue Scale) is a visual scale. The level of

perceived pain is marked on a straight horizontal line, and the

researcher or subject determines the intensity of pain. When

assessing pain, the researcher uses the scale reproduction based

on the marked points on the line to indicate no pain symptoms

and the strongest pain that the patient can imagine [2,5,6]. NRS

Numerical scale - on this scale, pain is rated from 0 to 10 in the

11-point range, where 0 is assigned the sentence “I do not feel

pain at all” and 10 is “the worst pain that cannot be imagined”

[7,8].

Prince Henry Hospital Pain Score - PHHPS - the scale is

applicable after thoracic surgery, cardio surgery and epigastric

surgery [2]. 0 - no pain when coughing1 - pain when coughing,

but not with deep breathing2 - pain only with deep breathing3 -

slight pain at rest4 - severe pain at rest All patients were treated

for pain according to PTBB (Polish Association for the Study of

Pain) guidelines published on 2018 [6]. Regular opioid infusion

of short-acting remifentanil was used for surgery, and patients

received fractionated doses of morphine, paracetamol, and

NSAIDs after surgery.

The statistical evaluation of the work was performed using

the statistics program, on the basis of the questionnaires and the

applied VAS scale and the numerical scale [9]. Sociologist E. Babbie

claims that a survey is the best method to gather information in a

larger group of respondents. It perfectly describes the collected

data on respondents [13]. A questionnaire was used to conduct

the research. According to the definition of Bauman and Plich,

it is “a technique of collecting information consisting in filling

out a questionnaire, most often by the respondent, of special

questionnaires, usually with a high degree of standardization”

[14].

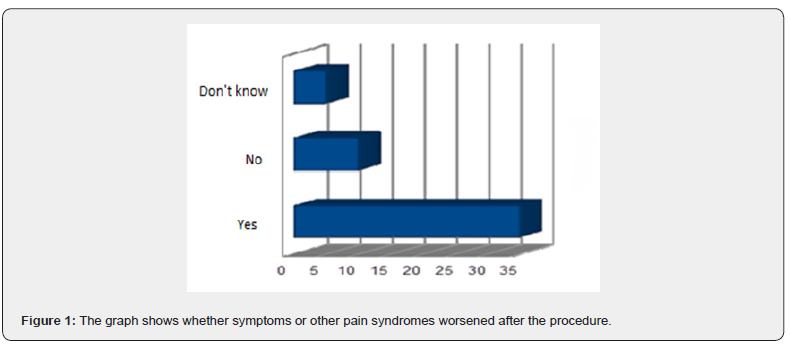

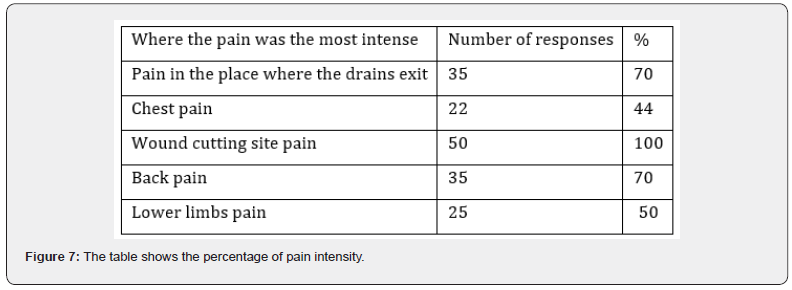

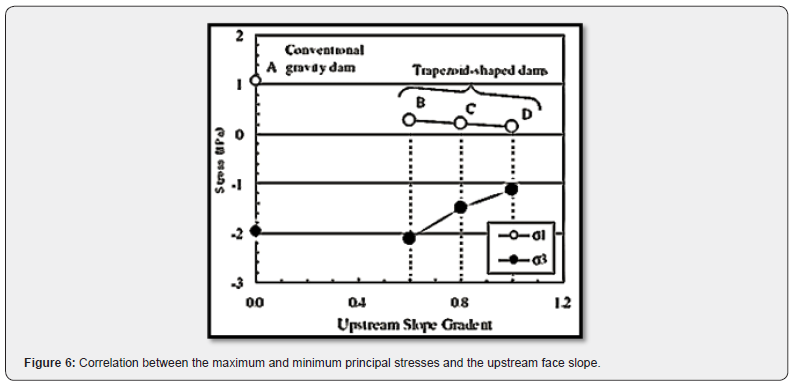

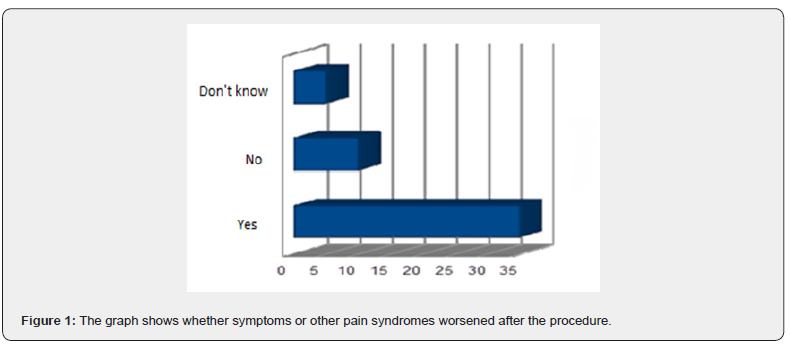

In the group of respondents, new pain ailments occurred in

25 people. Such feelings were not experienced by a smaller group

of respondents, as many as 20 respondents. 5 people remained

neutral. In the further part of the questionnaire, it was found

that 34% of patients report severe pain after surgery, there were

affirmative responses, while 40% of respondents stated that they

did not experience postoperative pain, and the remaining patients

were unable to provide answers. Additionally, when asked about

the severity of other pain ailments, as many as 35 respondents

out of 50 provided information that other pain syndromes had

worsened. On the other hand, as many as 10 respondents gave a

negative answer. 5 respondents remained neutral. The results are

shown below Figure 1 [15-17].

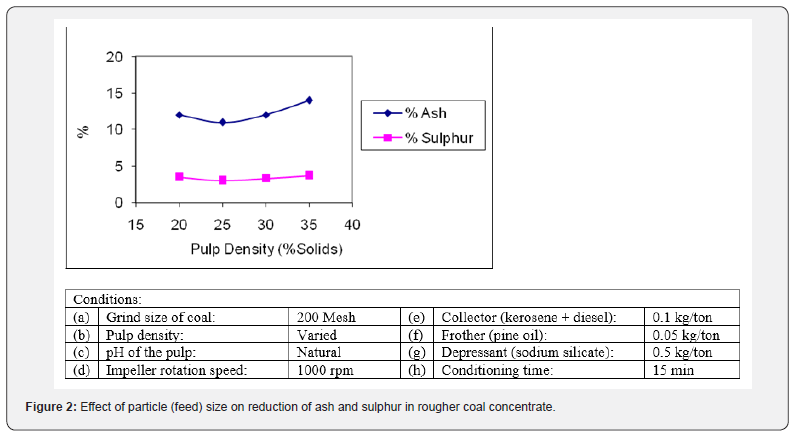

A large group of respondents were people for whom pain

hindered their daily functioning. More than half of the respondents,

i.e. 28 people, answered that pain is difficult in everyday life. No

problems in everyday functioning occurred in 10 people and 12

people chose the answer “I don’t know.” The result is shown below

Figure 2 [18].

A large group were also people who felt fear and anxiety

before the surgery, there were 35 of them, which constitutes 70%.

Before the surgery, 13 people said that fear and anxiety had no

effect on their well-being. Two people answered the question “I

don’t know”. To the question “Did the pain cause you fear unknown

so far?” The answers among the respondents were as follows:

as many as 40 people answered this question in the affirmative,

while 10% answered negative (Figure 3) [19].

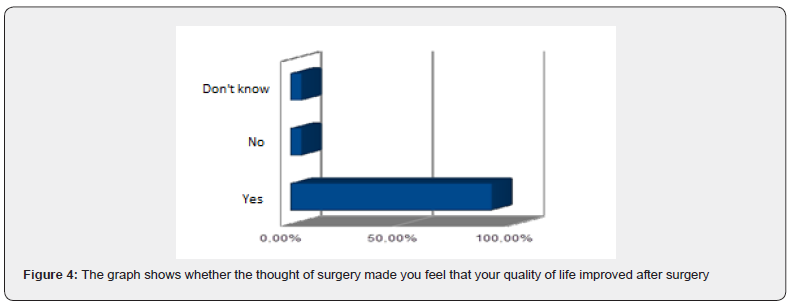

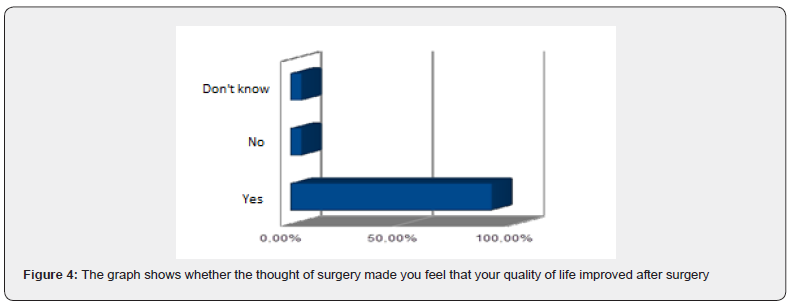

Among the respondents, 40 respondents know about the

possibility of alleviating postoperative pain. No information on

this topic appeared in 5 people. The least numerous answers were

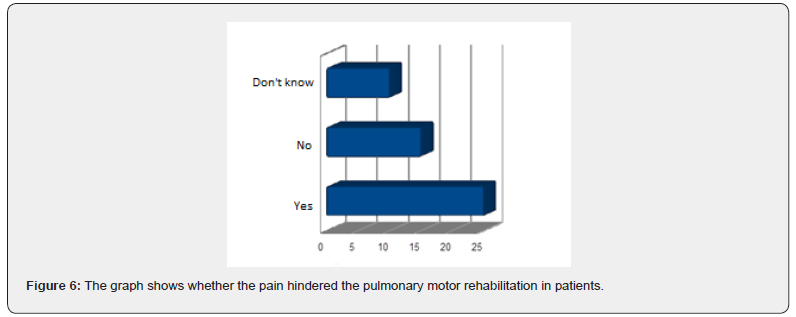

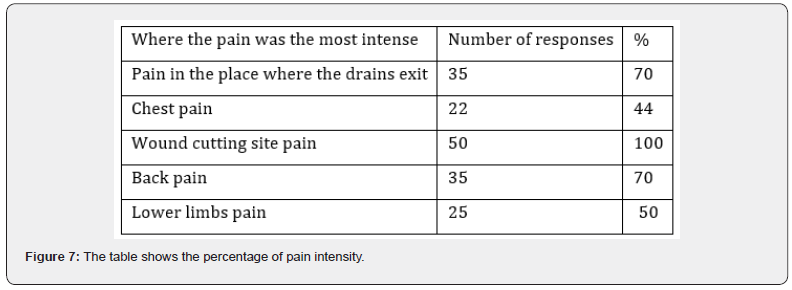

“I don’t know” [20] (Figures 4-7).

The study answered the questions that standard pain

management used in all cardiac surgery patients is not adequate

for palliative patients. They need more intensive analgesic therapy.

Standard pain therapy used routinely in the ward is not sufficient

for palliative patients. Patients suffer from pain especially

between 2 and 4 days after the procedure. The question whether

surgery and pain increase depression in palliative patients has not

been resolved. The stay in the ward and the pain will increase the

anxiety felt by the patients [21-23].

Pain and surgery have not been shown to influence

depression when assessed shortly after surgery. The greatest pain

was recorded on the fourth day after the cardiac surgery. This is due to the fact that the respondents suffer from postoperative

pain related to the performed procedure and it is perceived

differently than in non-palliative patients who, according to the

literature data, have the worst pain on the 2nd day after surgery.

Pain is related to the place where the drains are led out or where

the wound is cut. Pain intensity in cardiac surgery is the highest

among all the types of pain in surgery described so far [24-27].

Numerous studies show that most often, as in our work, that:

The indicated areas of pain after surgery are the medial part of

the chest, i.e. the area of the postoperative wound, the area where

the mediastinal and pleural drains are introduced. The group of

respondents stated that the operation would improve their quality

of life. There was no evidence of an increase in the drug after

surgery despite pain. High doses of drugs used in cardiac surgery

and the need for deep anesthesia reduce the level of anxiety due

to pain. The group of subjects required the use of higher doses

of pain medications. When the pain was stronger, respondents

reported the need for a higher dose of pain medication. The variety

of methods used to relieve pain and the techniques used were not

effective enough. Pain therapy is based on the close collaboration

of an interdisciplinary team. A nurse may give you a pain reliever

as needed. In the first few days, the painkiller is administered on

medical prescription, according to the hours indicated; in case of

prolonged acute pain, the rescue dose should be adjusted. The

drug should be administered by the most convenient route for the

patient, in the case of cardiac surgery patients it is usually central

access. The selection of agents should consider the analgesic

ladder, ranging from the less active drug to the more potent drugs

[28,29].

Pain in almost 90% of respondents caused unknown fear.

Anxiety is a sensation that can be attributed to a high level of

negative affect and a fear of possible danger or threat and a feeling

of being unable to predict and control them. Trait anxiety can be

viewed as a motive or acquired behavioral disposition through

which an individual may perceive non-threatening situations

as threatening, thereby reacting to them with drug states that

are not actually equivalent to them. The tendency to anxiety

reactions may cause higher levels of anxiety and depression in

the perioperative period. Pain can be a sensitive, early sign of

fear, especially in patients who have undergone cardiac surgery.

Preoperative fear associated with the procedure, awareness of

possible complications, general anesthesia and the patient’s

mental attitude increase the anxiety. Pain sensations after the

procedure increase anxiety in a large number of patients, which

contributes to the intensification of anxiety or fear, which results

in an extended recovery time. With each scale, we can evaluate

pain after cardiac surgery. The VAS scale positively correlates

with each other in zero and in the following days the possibility

of assessing pain. An important point is pain monitoring in the

intensive care unit is possible with all pain characteristics.

Post-operative pain impairs cognitive processes and limits

the possibility of performing physiotherapeutic procedures.

Weakened mental functioning extends the recovery period and,

after surgery, deteriorates functioning. Currently, the best-known

risk factors for disturbance of consciousness are old age, previous

stroke, renal failure, obliterating arteriosclerosis of the lower

extremities, and somatic stresses such as atrial fibrillation. The

study showed that patients diagnosed with palliative disease are

very sensitive to acute pain caused by surgery. Severe pain occurs

in 30% of them and in more than half of patients there is pain that

requires above-standard treatment.

The conducted studies of behavioral pain assessment in

cardiac surgery patients indicate that the overall health condition

of the patient should be taken into account in the assessment

of pain. Analysis of the collected data provided information on

the use of pain medications, pain assessment, and how patients

cope with emotions after cardiac surgery. A significant part of the

respondents experienced chronic pain of a significant degree, and

the number of these people increased significantly with the age of

the respondents.

Cardiac surgery procedures are a type of large and very

extensive procedures. The duration of the treatments, the way

they are performed, and pharmacotherapy have a great impact

on the patient’s condition. Pain after cardiac surgery is one of the

strongest postoperative pains. Pain requires a large contribution

of medical personnel and a large amount of pharmacotherapy

to improve the patient’s feelings. More pain medications are

sometimes needed to improve the quality of life of patients after

cardiac surgery and to relieve pain.

In our study, pain was examined on the 4th day after surgery,

where severe pain was found in a significant number of patients.

7/10 Failure to treat it causes a number of complications,

including unsuccessful surgery. Pain is also influenced by the

extent of the procedure and the degree of tissue cutting [2]. We

believe that the studied group of palliative patients is especially

prone to pain due to the specificity of end-stage disease. Although

few people die of pain, many die in pain and still more live in pain.

The psychological perception of a stimulus consists of four closely

related stages. The first and second stages can be assessed using

simple scales, for example the VAS visual-visual scale. The first

stage is a sensory-discriminatory experience, which in the second

stage causes a distress reaction with a small share of cognitive

functions. The third stage is suffering, which is a more complex

phenomenon related to the patient’s views on pain, including

complex reactions such as depression, anxiety, anger. This

stage is shaped by personality traits, ways of coping with pain,

experiences. The fourth stage is the behavioral expression of pain,

otherwise known as the pain behavior. It is determined by motor

efficiency and daily activities [10].

Nowadays, we can observe an upward trend in the willingness

to learn about the possibilities of analgesic therapy before

surgery. This reduces stress levels, anxiety and the occurrence

of depression. In our study, the patients were aware that

pain medications could be used to prevent pain. Most of the

patients expected them not to be hurt. In the further part of the

questionnaire, it can be stated that patients report pain after

surgery, and thus one of the factors hindering recovery is the

feeling of pain in various parts of the body. Difficult contact with

the patient causes mood swings, disturbances of the circadian

rhythm, delayed convalescence. Most of the answers were

affirmative [26]. On the other hand, 10% of respondents stated

that they did not experience postoperative pain.

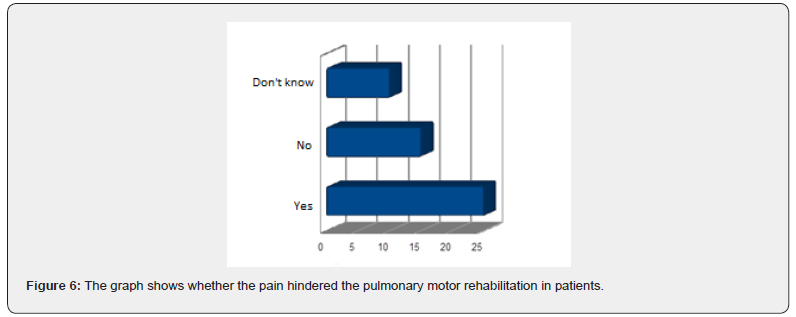

It was shown that the occurrence of pain significantly limited

the possibilities of rehabilitation. According to the literature, this

has a significant impact on the recovery period after surgery.

The study considers that the use of early rehabilitation shortens

the postoperative period and reduces the number of pulmonary

complications. The main task of cardiac rehabilitation is to

consolidate the results of conservative, interventional or surgical

therapy by stopping the disease progression, restoring the lost

psychophysical fitness and facilitating the return to active life

[20]. Due to the modern surgical techniques currently used, the

performance of procedures in increasingly elderly people, who

were previously disqualified due to the high risk of surgery, more

and more patients require rehabilitation [21,22]. Patients qualified

for cardiac surgery differ in the degree of risk. One group consists

of elderly patients with multivessel lesions, concomitant diabetes

mellitus and symptoms of heart failure. The second group consists

of patients with lower risk, young people with isolated, but not

eligible for angioplasty, lesions in the coronary vessels, without

heart failure and comorbidities. It is associated with a different

preparation of the patient for surgery, the risk of the surgery itself

and postoperative treatment, including rehabilitation [23].

In the perioperative period, the most important improvement

procedure is the activation of the mechanisms of proper lung

ventilation by breathing exercises: 4-track (upper costal, lower

costal, diaphragmatic, left and right chest side), the bronchial

tree toilet (positional drainage, learning effective coughing

and expectoration, breathing exercises with water bottle,

flutter, etc.); placing the lower limbs from which the material

for transplantation was made in a position that facilitates the

outflow of blood; reducing the tension of the abdominal press

during isometric efforts and changes in position from lying down

to sitting and vice versa; active exercises of the upper and lower

limbs (coordination of movement with breathing); active lower

limb exercises for thromboprophylaxis; starting a sick person and

preparing for self-service; isometric and relaxation exercises [23-

25].

Working with a patient with acute pain and palliative disease

requires professional knowledge of how to relieve pain, support

and demonstrate understanding in proportion to the patient’s

condition. The interdisciplinary team must be aware that physical

suffering affects the mental sphere [17]. Therefore, as pain after

cardiac surgery is one of the most severely felt types of pain,

especially in the first few days, treatment should be started to

relieve pain as effectively as possible until full consciousness is

regained upon recovery from general anesthesia. Opioids (mainly

morphine, tramadol) and drugs such as paracetamol, pyralgine,

and ketoprofen are the best [18,19].

The nurse’s participation in the treatment of postoperative

pain is based on her preparation for the care of a pain patient.

In Poland, such patients may be cared for by nurses who have

completed a qualification course or specialization in anesthetic

and intensive care nursing, or a specialist course in acute pain

therapy in adults. Education increases knowledge about pain

and encourages patients to participate in pain management. It

should cover analgesic methods, methods of pain measurement,

establishing an analgesic action plan, and explaining the

importance of honesty in pain assessment and treatment for

overall therapy success [14,15]. Assessing acute pain care is

difficult because pain is a subjective symptom that people

perceive differently. After surgery, insufficiently treated pain may

cause prolonged suffering, rehabilitation, aggravate depression

and anxiety, and affect the occurrence of postoperative delirium;

it may increase the number of complications [16].

The analysis of the collected results and the

conducted

research led to the following conclusions. In our work, severe

postoperative pain occurred on the fourth day after the surgery

in palliative patients undergoing cardiac surgery. We believe that

palliative patients are more prone to pain than the group of patients

without comorbidities. The pain concerned the operated site,

especially the chest, and it was shown that the occurrence of pain

significantly limited the possibilities of rehabilitation, especially

increasing the risk of pulmonary complications. Monitoring

and assessment of pain in the postoperative department is

possible using the VAS scale. The conducted studies allow for the

behavioral assessment of pain in patients after cardiac surgery, it

has been shown that the pain did not change the level of the drug

after surgery in palliative patients.

To Know more about Palliative Medicine & Care

Click here: https://juniperpublishers.com/index.php