JOJ Sciences - Juniper Publishers

Abstract

Due to the growing human need for dam construction, as well as the progress and development of this industry, engineers are always trying to move towards the two factors of reducing costs and protecting the environment. CSG trapezoidal dams are a new type of dam that has been used extensively in countries in recent years. Cement, sand and gravel are used in dam bodies presenting properties between concrete dams and earth dams. The raw materials used in these dams include riverbed sand, drilling debris and aerated rocks, and so on. Indicating that the choice of aggregates among these materials is not very strict and there is no need for grain sorting equipment. As a result, it not only reduces resource and environmental degradation, but also reduces operating costs. Distinctive features of this type of dam are “design rationalization”, “material rationalization” and “ construction rationalization”. The specialized design of these dams is a combination of finite element design and dynamic analysis method. Because these two methods can simultaneously provide a direct and reasoned assessment of external and internal stability. In this research, the design parameters of the dam with CSG materials have been presented.

Keywords: Trapezoidal dams, Cemented sand, CSG materials, Design rationalization, Material rationalization, Construction rationalization

Introduction

Trapezoidal dams with CSG materials are a new type of dam with high development potential, which are a combination of trapezoidal dams and CSG dams, their main purpose is to rationalize the use of materials, as well as improving the design criteria and implementation stages of the dam. Since the raw materials used in this dam are obtained from the materials of the dam site and all operations are performed with simple and general tools, the volume of excavation for raw materials is reduced. As a result, this type of dam, in addition to significantly reducing costs, can use local materials in high amounts according to the requirements of the dam materials to avoid vegetation degradation. Hence, the dam is also called Zero emission dam and is known as an environmentally friendly structure. The CSG trapezoidal dam emphasizes the rationalization of materials and also helps to improve design and construction [1-4].

Rationalizing the design: The surrounding environment (foundation) could be chosen flexible. Because CSG material barrier dams can reduce the required strength in the dam body as well as the bedrock and foundation. Rationalization of materials: By taking benefit of lower quality materials, the range of materials could be expanded. Since trapezoidal section CSG dams require less strength, materials with lower nominal strength could be used. Rationalization of construction: construction of trapezoidal dams with cemented sand materials is possible by using very simple production machines and equipment.CSG Trapezoidal Dam is made of cemented sand and gravel (CSG) material as the main material of the dam body and a protective concrete layer that is poured on its surface to increase durability. In addition, inspection galleries, structural concrete and water seepage control concrete are constructed in dam downstream. Enriched CSG is used at the bottom of the dam to ensure durability.

Trapezoidal dam with CSG materials specifications

The main material of the dam body is cemented sand and gravel (CSG), which is covered with a protective concrete layer to ensure the durability and impermeability of the dam wall. In the lower part of the dam, instead of CSG, enriched CSG (the same CSG with more cement) is used to create a strong bed and a strong connection between the dam body and the bedrock. Inspection galleries, structural concrete and water seepage control concrete are constructed downstream of the dam to ensure sufficient length of the sealing blanket. One of the most important features of trapezoidal dams with CSG material is its design as an elastic body. This design allows the implementation of various sections such as water pipes, inspection galleries inside the dam body and emergency overflow on the spillway, just like concrete dams [5,6].

CSG Trapezoidal dams possess the advantages of both trapezoidal dams and CSG materials and have three rational justifications simultaneously:

i. Rational design justification: The required strength of dam materials can be reduced by the seismic stability performance of the dam and its trapezoidal shape.

ii. Rational justification of construction: Construction operations can be carried out quickly by simplifying construction tools.

iii. Rational justification of materials: Since the required strength of dam materials is low, a wide range of material could be adopted.

Figure (1) shows the design process of a CSG trapezoidal dam. In the design process, elastic stresses, considering the dead load, hydrostatic pressure, definite reaction pressure and sediment pressure and the force caused by the earthquake, are likely to be created to withstand the maximum stress developed in the dam body.

Trapezoidal dam

A trapezoidal dam is a dam whose cross section has the trapezoidal geometric shape. What should be considered in the design of these dams are the slopes of the body. The upstream and downstream slopes of the body are selected so that the base reaction force (foundation) is always compressive. External and internal stabilities are two important parameters in the design of any structure. External stability is the same as the reliability against slipping or overturning of the structure, and internal stability is responsible for providing the required strength to major internal stresses [6,7,8].

Required stresses and strengths (internal stability)

Stress analysis

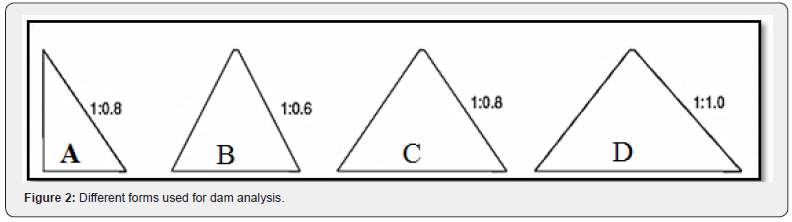

To investigate the stress in trapezoidal dams with CSG materials, two-dimensional FEM analysis in plain strain conditions was performed for static and dynamic analysis. The loads considered in the static analysis are the dead weight of the dam body and the hydrostatic pressure due to the reservoir water. Due to the low-pressure effect of sediments on the dam body with a gentle upward slope, they are not considered in the analysis. The dynamic loads for dynamic analysis are the inertia force of the dam body and the hydrodynamic pressure applied to the upstream dam surface. The hydrodynamic pressure is calculated assuming that the reservoir is designed as incompressible flow. Figure (1) shows the shapes of the dam model used for analysis. In the case of Model A, the upstream face is vertical and downstream slope is 1:0.8, the same as a typical weighted concrete dam. The upstream and downstream slopes are symmetrical for models B, C and D and these slopes are 1:0.6, 1:0.8 and 1: 1, respectively. The height of the dam is 50 meters, and the depth of the water reservoir is 90% of the height of the dam. The ductility of the foundation is considered only in the static load analysis [6].

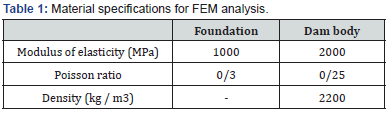

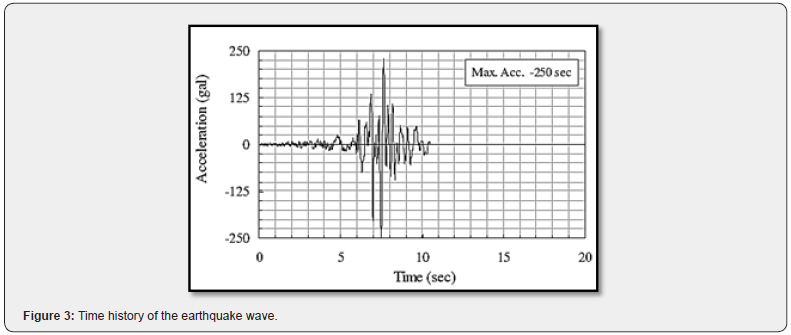

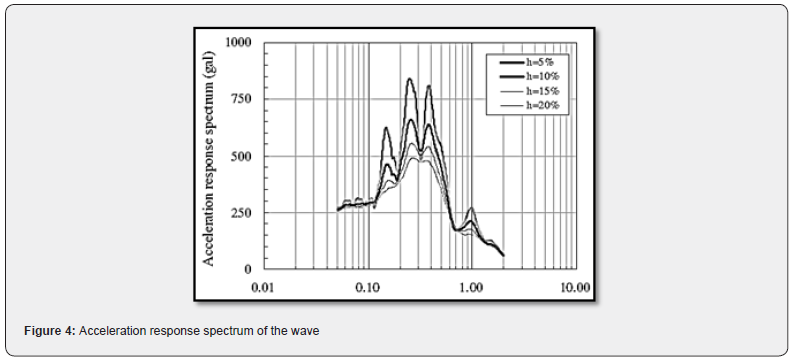

Since the CSG materials properties are very variable based on the characteristics of the raw materials obtained from the dam site vicinity, the material properties are assumed to be constant values as shown in Table (1). The incoming earthquake wave used for dynamic analysis is the acceleration recorded of the Hitokura Dam during the 1995 Nambu Hyogo-ken earthquake at the lowest inspection gallery. The maximum amount of acceleration is set to 250 gal and the waves enter from under the dam in a horizontal vibration. Figure (2) shows the time history of the acceleration wave and Figure (3) represent the acceleration response spectrum of the earthquake wave.

FEM analysis results

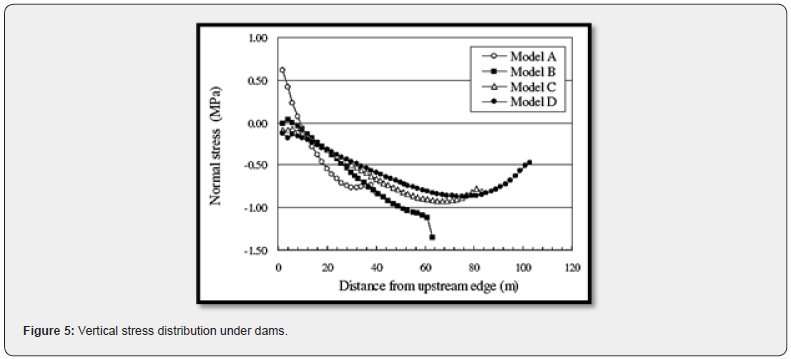

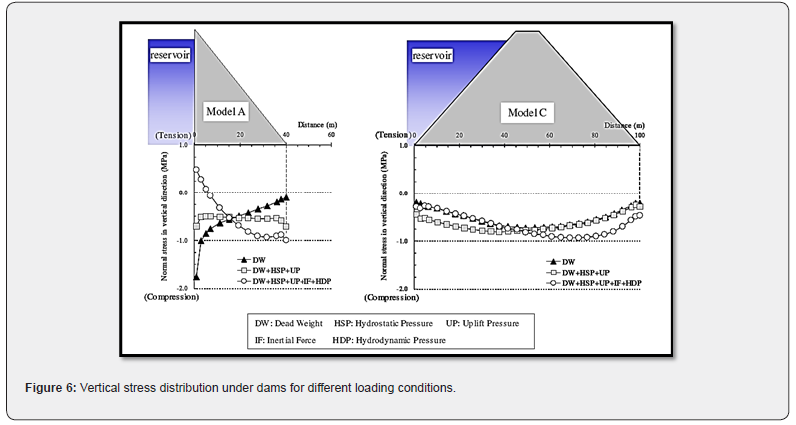

Stress distribution along the dam body Figure (4) shows the vertical stress distribution at the bottom of the dam in the maximum acceleration. Positive values indicate tensile stress, and negative values indicate compressive stress. The figure shows that the stress in models A and B is greatly affected by the position (distance from the upstream), but in C and D models, the stress corresponding to the position changes slightly. Figure (5) shows the vertical stress distribution at the bottom of the dam body under different loading conditions in models A and C. Its value in dynamic conditions is proportional to the time in the maximum acceleration. Compared to Model A, the fluctuations of the vertical stress distribution are lower in Model C and this is one of the advantages of trapezoidal dams [6].

The relationship between maximum stress and the slope of the trapezoidal dam surface

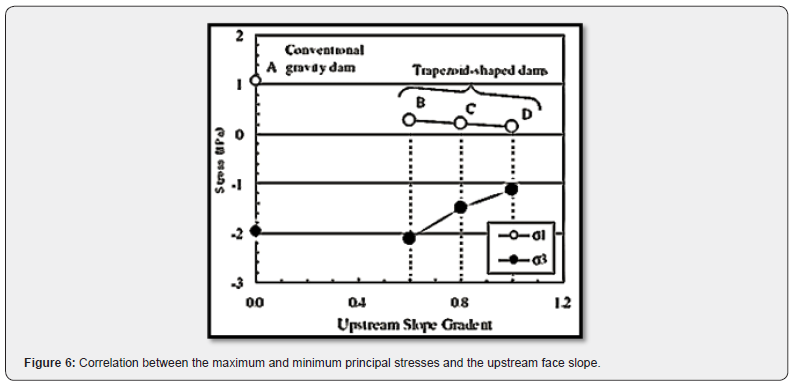

Figure (6) shows the relationship between the maximum and minimum values of the main stresses and the upstream face slope of models A, B, C and D. The figure shows that the gentle slopes result in lower stresses. The maximum tensile stress of model A (right triangular barrier) is 1.08 MPa. The tensile strength required for concrete in weighted concrete dams is approximately 10% of the compressive strength. Given this relationship, it is found that the compressive strength required in right-angled triangular dams to secure the tensile strength of 1.08 MPa should be 10 times the tensile strength, ie 10.8 MPa. The maximum compressive stress in model A is 1.97 MPa. In the trapezoidal section dam (Model C), the maximum tensile stress is 0.21 MPa, meaning that the required compressive strength is 2.1 MPa. The maximum compressive stress in model C is 1.49 MPa [6].

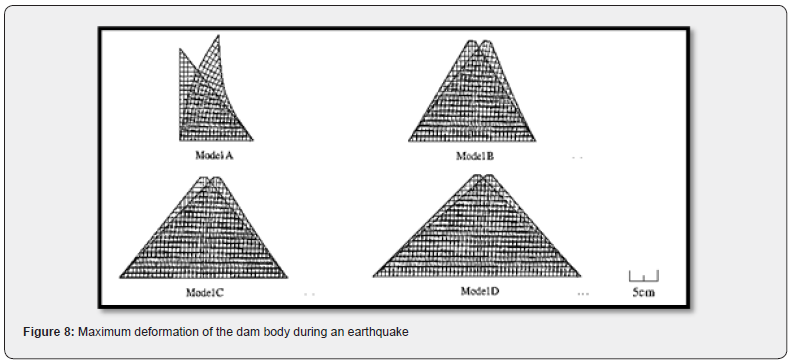

Figure (7) shows the maximum deformation of the dam body. In model A (barrier with right triangle cross section), flexural deformation is dominant, while in trapezoidal dams, especially models C and D, shear deformation is dominant. From the mentioned results, it can be infered that the compressive strength required in trapezoidal dams is much lower than dams with a right triangular cross section. In addition, it can be understood that the lower the slope, the lower the strength required for the trapezoidal dam.

Overturn (external stability)

From an external stability point of view, it is almost impossible for the dam to overturn due to the trapezoidal geometry. Trapezoidal dams, on the other hand, are designed to withstand vertical stress across the dam, both under normal conditions and under dynamic earthquake loads, to be safe from overturning. These conditions are different in right-angled triangular dams. In right-angled triangular dams, vertical stresses tend to be tensile around the dam toe during an earthquake, and to overcome this tensile stress, the dam is connected to the bedrock. However, for a trapezoidal dam, it is not necessary to connect the dam body to the bed, because these types of dams are designed in such a way that the vertical stresses along the entire bed surface are compressive, indicating a very big difference between trapezoidal dams and dams with a triangular cross section [7].

Slip

Since a trapezoidal dam is designed in a way that the bottom surface is larger than a right triangular dam and is symmetrical on both sides, the vertical stresses in the vicinity of the bedrock remain compressive and the shear stresses rarely change. Therefore, due to the frictional force between the dam body and the bedrock, the dam remains stationary and will not slip [7,8].

Foundation bedrock condition

Weighted concrete dams are designed to perform integrated with the foundation bedrock to prevent possible overturning and slipping. However, in trapezoidal dams with CSG material (especially in trapezoidal dams with upstream and downstream slope of 0.8: 1) since the vertical stresses along the dam body are compressive and due to friction between the body and foundation bedrock are always considered safe against slipping and overturning. In weighted concrete dams, the foundation bedrock must form a hard and rigid environment, while trapezoidal dams with CSG materials can also be funded on relatively flexible environments. The required strength for trapezoidal dams with CSG materials, in addition to the height of the dam and the slope ratio of the dam body, is proportional to the ratio of modulus of elasticity (EC) of CSG to modulus of elasticity of bedrock (ER). More precisely, the larger the ER / EC, the greater the tensile stress (due to bending) is applied to the lower parts of the dam. As a result, we will need more strength in these areas [8,9]. Also, since the modulus of elasticity of CSG is approximately 0.1 of ordinary concrete, the bedrock will have better conditions in terms of ER / EC ratio for strength in trapezoidal dams with CSG materials. Of course, this does not mean that trapezoidal dams with CSG materials can be built on any stone or foundation.

Conclusion:

Differences in design procedures of trapezoidal dams with CSG materials and weighted concrete dams.

CSG trapezoidal dam

i. Obtaining CSG strength (testing on materials)

ii. Safety study of the dam body against internal stress

iii. Safety study against slipping

iv. Deciding on the shape of the dam body In trapezoidal dams with CSG materials, the design is based on the properties of the material, while in weighted concrete dams, the dam design is based on minimizing the volume of the dam.

In weighted concrete dam design, the following items are taken into consideration:

i. Safety study against overturning

ii. Slip safety study

iii. Deciding on the shape of the dam body

iv. Safety study of the dam body against internal stress

v. Obtaining the required design strength

To Know more about JOJ Sciences

Click here: https://juniperpublishers.com/index.php

I wasted a lot of money trying to find the right medication for my moms dementia all to no avail until Dr Erayo showed up and eradicated the stigma with the natural roots and herbs i ordered from him , my mom took it for 21days and she was cured from her dementia.

ReplyDeleteGod have use Dr Erayo herbal home to cure my mom, thank you so much Dr Erayo I am so happy. You can email Dr Erayo for help drerayoherbalhome@gmail.com

or whatsapp him on +2348151937428

website---- https://alternativeherbs.weebly.com

Youtube link---- https://www.youtube.com/channel/UCSp2m-_EHnCRQT4gYYTQWtg

FB page---- https://rb.gy/yuofn6