Academic Journal of Polymer Science - Juniper Publishers

The purpose of this study was to evaluate the effect

of adding various concentrations of castor oil (2% and 4% v/v) on the

properties of edible films based on carboxymethyl cellulose (CMC).

Moisture content, water solubility, tensile strength, elongation at

break, elastic modulus, water vapor permeability, optical and thermal

properties and antioxidant activity of the films were examined. The

results demonstrated that the presence of castor oil led to a decrease

in moisture content, water solubility and mechanical strength of the

films. The film containing 4% of oil showed the highest water vapor

permeability. The optical properties measurement represented that all of

the samples were transparent. By the addition of castor oil, the

antioxidant activity of the films improved largely. Thermal properties

of the samples had also been investigated and it was determined that the

effect of castor oil on the melting point was negligible. Finally, the

performance of the coatings for protecting fresh apples was studied with

measuring the pH value of apples and performing some field test.

Every year a large portion of foods, especially

fruits and vegetables, from the time they are harvested until they reach

to consumers, go through different kinds of qualitative and

quantitative deterioration and loss [1]. Various factors are involved in

food deterioration such as microorganisms, mechanical damages, time and

light. Therefore, if we fail to protect the food, it can be damaged

within hours or days [2]. Currently, there are numerous technologies

used for the purpose of fruits and food preservation. Some include

controlled atmosphere storage and modified atmosphere packaging,

innovative osmotic dehydration technologies, electro-osmotic dewatering ,

thermal pasteurization, and gaseous ozone and ozonated water treatments

[3,4]. One way to prevent or delay the food deterioration is the use of

edible coatings. During the past decade, edible coating has been widely

used for this purpose [5-9]. Some advantages of edible coatings include

extending shelf-life of fresh fruits, reducing amount of waste produced

from packaging processes, improving appearance and fulfilling

environmental safety, as well as enhancing nutritional properties due to

containing lots of beneficial biopolymers and biological compounds

including polysaccharides, proteins, and lipids. Moreover, they decrease

water loss and retard ripening of fruits due to barrier mechanism, and

are also able to enhance antioxidant properties of fruits and vegetables

[10-13].

Any material used to cover foods in order to enhance

the shelf life, which may be eaten with the food, is an edible coating

[2]. Various studies have been conducted on the properties and

applications of edible films and coatings [14-18]. The initial studies

on edible coatings can be traced back to 1967, where Hardenburg studied

the application of wax used by Chinese on citrus fruits [19]. Since 1986

there were various studies on edible coating including wax emulsions,

oils, cellulose, chitin and chitosan, and their impact on diverse

properties of fruits and food like shelf-life [20-26]. However, more

research is needed because there are no edible films that can be used

for all purposes. As other technologies, edible coatings can also bring

some challenges like undesirable tastes caused by presence of wax

materials, hydrophilic nature of edible coatings which makes them

moisture-sensitive and limits their moisture-barrier performance, poor

adhesion and coverage, and insufficient mechanical properties of

biopolymers comparing to the synthetic ones [27,28]. In general, an

ideal edible film must have characteristics such as being nontoxic,

allergenic or indigestible materials, protecting foods from mechanical

damages, good adhesion, maintaining the appearance of the product and

having an easy and economical production [2]. Proteins, carbohydrates

and lipids are the main film forming agents in edible coatings [29].

Generally, lipids will reduce water transmission in edible coatings,

polysaccharides are good for controlling the transmission of gases and

protein-based films have proper mechanical strength [29]. These

materials can be used either individually or as a blend (composite

films) in edible coatings [29].

Carboxymethyl cellulose (CMC) is a conventional

polysaccharide, which is one of the common derivatives of cellulose. CMC

is an anionic polysaccharide, which unlike cellulose is soluble in

water [30]. CMC has wide variety of uses in different industries such as

foods and coatings [31] and therefore is an excellent choice for edible

coatings because it has no toxic or allergic effects. It is one of the

most desirable polysaccharide polymers due to its excellent properties

including perfect film forming ability, availability, low price and high

viscosity, which can be used to produce both edible and degradable

films and coatings [31]. In most cases, a plasticizer must be added to

the film forming solution in order to reduce the brittleness of CMC

films. However, using plasticizers will affect the mechanical and

permeability properties of the films [32]. The most common food grade

plasticizers are some polyols including glycerol, mannitol, sorbitol,

and sucrose [33]. Glycerol is a clear, colorless and odorless liquid,

which is soluble in water due to its hydrogen bonds. This component

reduces the film's fragility by being located between the CMC chains

(enhancing chain mobility) and also by absorbing water [34]. The

beneficial properties of some lipids, including their good compatibility

with other film constituents and good barrier properties against water

vapor and other gases, make them an ideal choice for edible coatings and

films [35,36]. Lipid compounds that are commonly used to make films and

edible coatings include edible oils, fatty acids and waxes [37]. The

efficiency of lipid used in edible films and coatings depends on the

nature of the lipid, particularly its structure, hydrophobicity and its

interaction with other components in the system [2]. Castor oil is a

viscous and non-volatile liquid with a pale yellow color. High amount of

both resinoleic acid (RA) and double bonds results in oxidative

stability of the castor oil as well as long shelf life [37]. The

antioxidant activity of castor oil also makes it an excellent choice for

use in edible coatings in order to prevent food degradation.

In this study, the effect of castor oil on

mechanical, optical, physical and thermal properties of CMC-based edible

films along with their antioxidant activity have been investigated. The

results showed potential use for castor oil in edible coatings.

Carboxymethyl Cellulose (CMC) with purity of 99.6%

and viscosity of 2787 cps ; Castor oil with density of 0.959 g/mL [38]

and Polysorbate 80 (Tween 80) were purchased from Pasargad Novin

chemical Co. Glycerol (USP grade) was purchased from PALMAC. Analytical

grade of Ascorbic acid was obtained from Merck (Darmstadt, Germany). CMC

is a white, granule-shaped powder used for increasing the viscosity.

Castor oil consists of various fatty acids mostly containing ricinoleic

acid (12-hydroxyoctadecenoic acid) [39]. Tween 80 which is a highly

viscous liquid, is used as a surfactant [40,41].

Film forming solution was prepared by adding 1 g of

CMC to 100 ml of distilled water (1% w/v). The system was under

continuous agitation by magnet stirrer and the temperature was set on

75℃. After 40 minutes, a clear solution was achieved. Then 1 ml of

Glycerol (as plasticizer) was added to the film forming solution and

stirring went on for another 15 minutes. At this point, the film forming

solution was ready in order to prepare the control films (films

containing no castor oil). To do so, 25 g of the solution was poured in

the middle of plastic circular plates (with 10 cm diameter and 1 cm

height) and dried at room temperature in about 48 hours. Other film

samples were prepared as described below:

a. CO-2: 0.2 ml of Tween 80

(proportional to castor oil) was added to the film forming solution

under continuous stirring. After 15 minutes, 2 ml of castor oil was also

added to the solution and the stirring continued for another 30

minutes.

b. CO-4: 0.4 ml of Tween 80 was

added to the film forming solution under continuous stirring. After 15

minutes, 4 ml of castor oil was also added to the solution and the

stirring continued for another 30 minutes.

c. AA1: 1 g of ascorbic acid was added to the film forming solution and the system was under stirring for 10 minutes.

d. AA2: 0.4 ml of Tween 80 was added

to the film forming solution under continuous stirring. After 15

minutes, 4 ml of castor oil was also added to the solution and the

stirring continued for another 30 minutes. Following that, 1 g of

ascorbic acid was added to the solution and stirring continued for 10

minutes.

The procedure of preparing film from all of the

mentioned solutions was similar to the control films. Also, to do some

field tests and measuring pH the sample films were applied on apple by

silicon brush. All the dried films were peeled of the plates and kept in

a desiccator at 25℃ and 50% relative humidity (RH) for 72 hours until

further evaluations.

A hand-held micrometer was used to measure the film

thickness. For each film, the thickness was measured in several areas

(at least at five locations) and the final thickness was reported as the

average value.

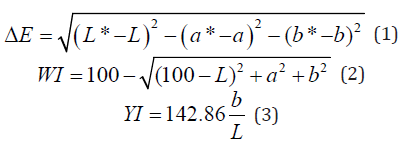

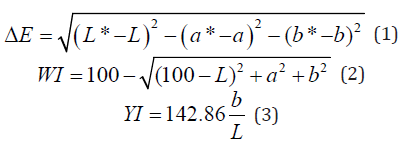

The color of each film was monitored using a

calorimeter in the CIE Lab system. The films were placed on a standard

white background (L*= 89.7584, a* = -0.5083 and b* = -2.0585) and their

“Lab” values were determined. The color difference (ΔE) between the

films and the standard background, whiteness index (WI) and yellowness

index (YI) were calculated using the following equations:

Where “L” value represents the lightness of the

sample (varies from 0 (black) to 100 (white)), “a” represents the

redness-greenness balance of the sample (from negative (green) to

positive (red) values) and “b” indicates the yellowness-blueness balance

of the film (between negative (blue) and positive (yellow) values)

[37].

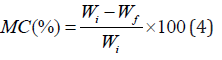

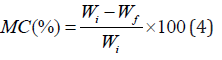

The moisture content of each film was determined

based on weight loss. In this method, the film was first weighed and

then placed inside the oven at 110°C. The weight of the film was

measured every hour until it reached a constant value. Finally, the

amount of moisture in the film was obtained from the difference between

the initial and the final weight. The percentage of water in the film

was calculated by the following equation:

Where Wi is the weight of the film before being

placed in the oven and Wf is the weight of the film after that. The test

was repeated three times for each sample to secure a more accurate

result.

The solubility of the film in water was evaluated

based on the method described by Gontard et al. with some modifications

[42]. The initial weight of the film was measured after drying the

sample at 110 °C. Then the dry samples were immersed in 100 ml water for

5 hours at 25°C under continuous stirring. After filtration, to

determine the final dry weight, the portion of the film, which was

undissolved in water, was placed in an oven at 110°C to reach a constant

weight. The water solubility percentage of the film was calculated by

the following equation:

Where Wi is the initial dry weight and Wf is the final dry weight of the films (after immersing in water).

In order to obtain a consistent result, water

solubility of each film was evaluated three times and the average value

was reported.

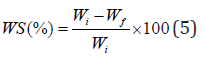

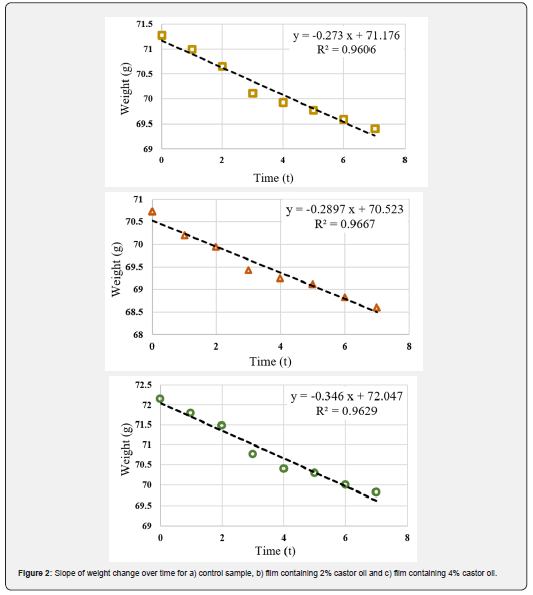

The water vapor permeability of each film was

determined based on the instructions provided by ASTM E96 [43]. Cups

with an average diameter of 3.5 cm and a depth of 1 cm were used to

determine WVP. The films were cut in circle shapes with slightly larger

diameter than of the cup. After placing 3 g of water (RH = 100%) in each

cup, they were covered with sample films. Each cup was placed in a

desiccator containing silica gel (RH = 0%) and the temperature was

maintained at 25°C. The cups were weighed every 24 hours (With a

precision of 0.0001 g). The weight change of the cup was plotted as a

function of time and the slope of this curve (weight change versus time)

was calculated by a linear regression. Water vapor transmission rate

(WVTR) was obtained by dividing this slope by the transmission area (m2). Finally, the WVP was evaluated from the following equation:

Where P is the saturated vapor pressure of water at test temperature (25℃), R1 is the RH inside the desiccator, R2 is the RH inside the cup and X is the film thickness (in meter).

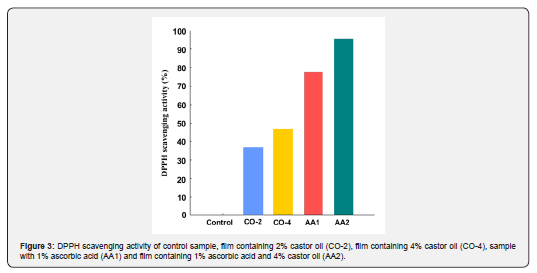

The antioxidant activity of the film samples was

investigated through DPPH radical scavenging activity based on

instruction of Brand-Williams et al. [44] with some modification. This

test is based on the ability of the samples to donate hydrogen or

electron and is evaluated by measuring the amount of color reduction of

2,2-diphenyl-1-picrylhydrazyl (DPPH) solution in methanol (a solution

with purple hue). DPPH radical is absorbed at 517 nm but the amount of

absorbance decreases when it is exposed to an antioxidant. To evaluate

this property, 25 mg of the sample film was added to 5 ml of distilled

water and the mixture was stirred continuously by a magnet Stirrer. Then

0.1 ml of the resulted solution was added to 3.9 ml of DPPH solution

(0.1 mM methanol solution) and the sample was incubated in darkness for

one hour at room temperature. The sample’s absorbance was then measured

at 517 nm and the scavenging activity was calculated by the following

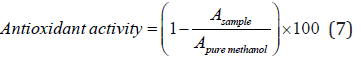

equation:

Where A is the absorbance at 517 nm.

Tensile strength, elongation at break and elastic

modules of the films were measured by the universal testing machine. The

test was conducted based on the ASTM D882-91 standard [45]. For this

purpose, the films were cut into rectangle shapes (about 2 cm x 10 cm)

and placed between the grips. The initial space between the grips and

the crosshead speed were set at 50 mm and 10 mm/min, respectively (with 1

kg load cell). Mechanical properties were evaluated for three

replications of each sample.

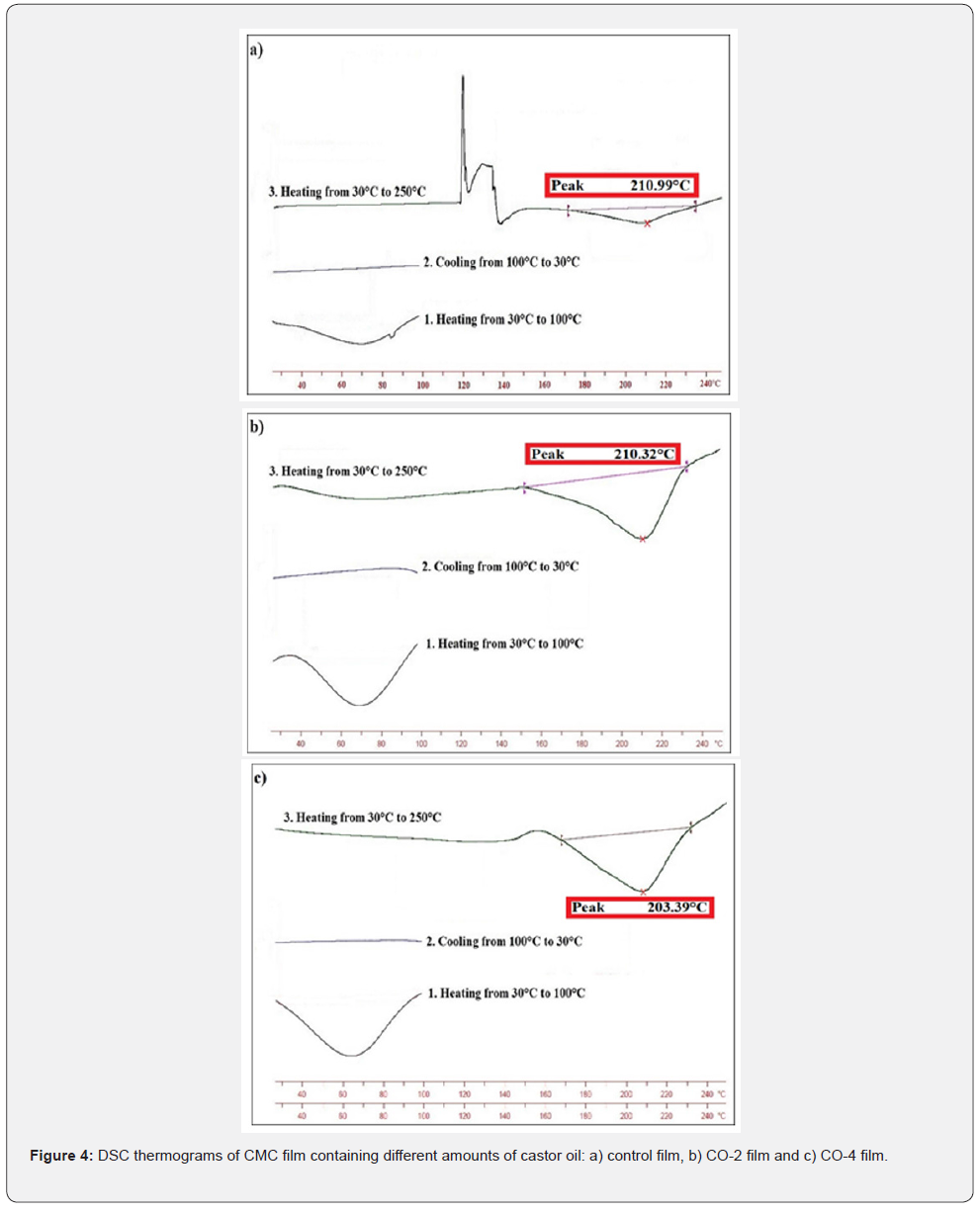

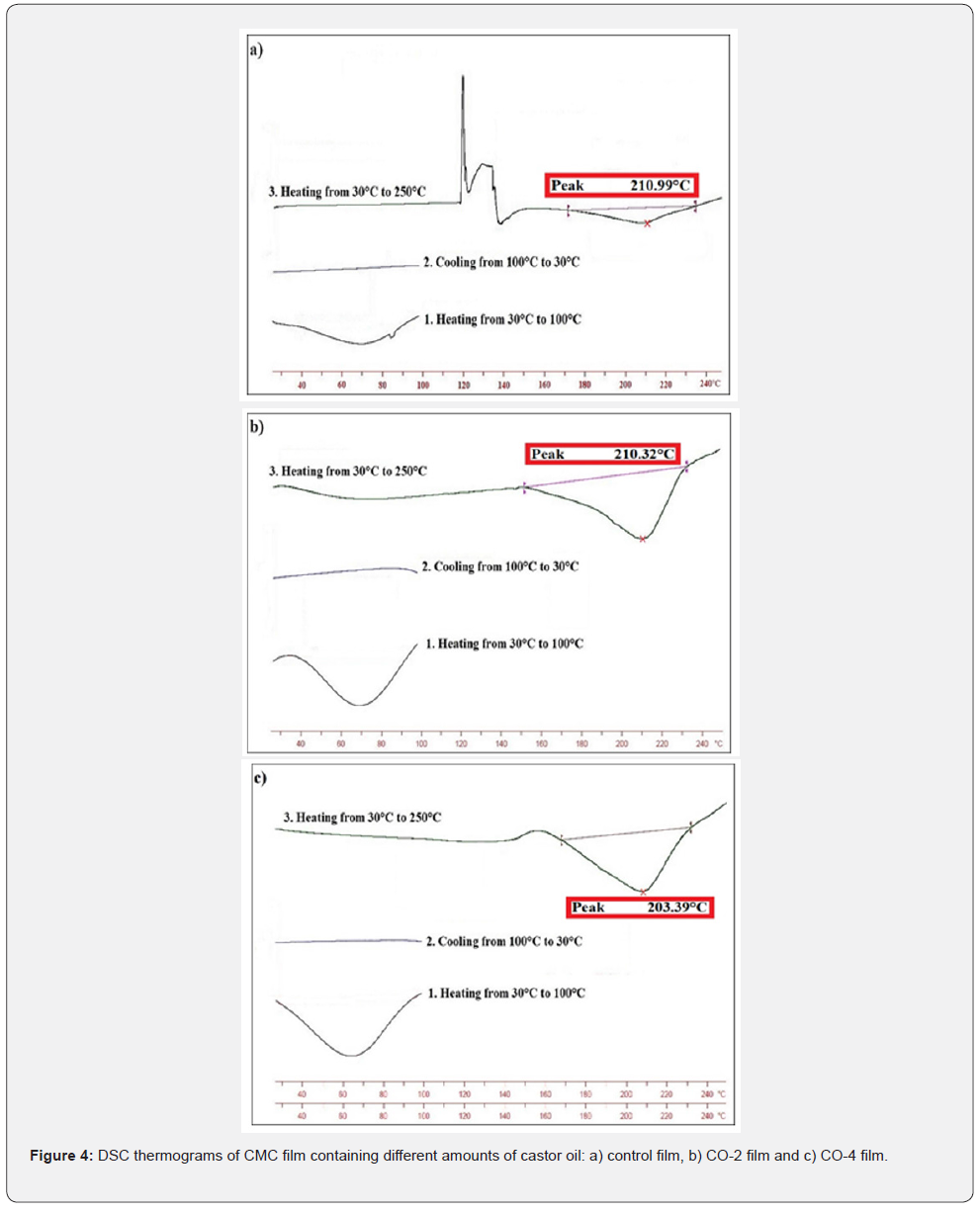

The thermal properties of the films were investigated

by DSC test, which is described below. Approximately 5 mg of the film

was placed in an aluminum pan. The reference was also an empty aluminum

pan. Thermal behavior of different films were measured at a thermal

scanning rate of 5℃/min in three steps. First heating from 30℃ to 100°C,

then cooling from 100℃ to 30°C and last heating again from 30℃ to

250°C. The melting point (Tm) of the films was determined in this

process.

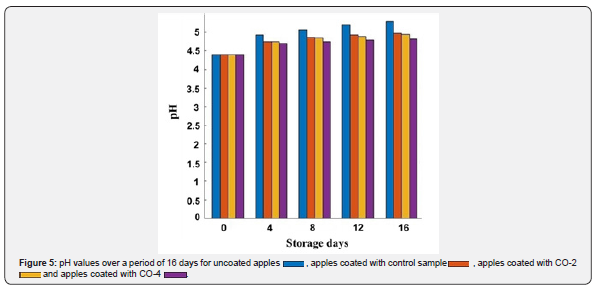

To evaluate the pH of apples, 10 g of each sample

(with its coating) was added to 100 ml of distilled water and then

stirred for 30 minutes. After filtering the mixture, its pH was measured

and reported by a digital pH-Meter. In order to compare the results,

the same process was performed on control apples (apples with no

coating). The pH measurement was started immediately after applying

coating on the apples and was repeated every 4 days. During the test

process, apples were kept at room temperature.

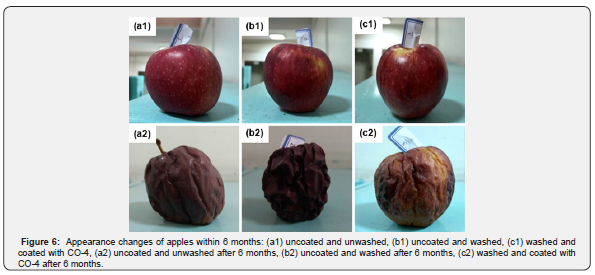

To evaluate the performance of the coating, three apples were picked from a store and processed as described below:

a. The first apple was kept unwashed.

b. The second one was washed.

c. The last one was washed and then the CO-4 film forming solution was applied on it with a silicon brush.

All three samples were then kept at a dark place at room temperature for six months.

All the Data were analyzed using MATLAB and

Statistics Toolbox Release R2018b, The MathWorks, Inc., Natick,

Massachusetts, United States. The results were reported as mean ±

standard deviation.

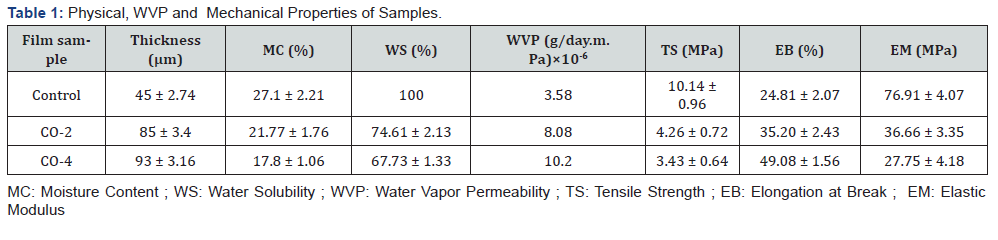

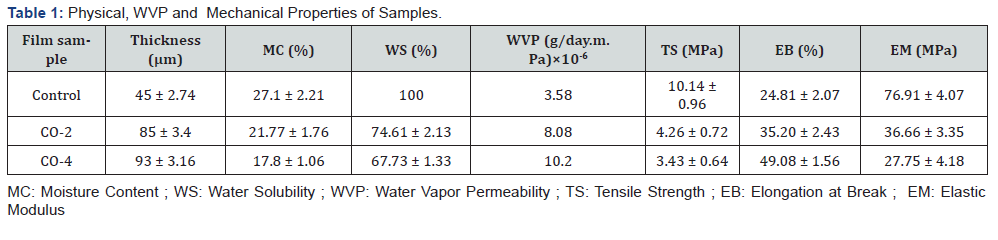

Thickness is an important parameter that affects some

properties of the films such as transparency, permeability and

mechanical strength [46]. The thickness of the films varied from 45 to

95 microns. As shown in Table 1, the thickness of the control film

(without castor oil) was 45 microns and with increasing the oil content

in the samples, their thickness increased until it reached 95 microns

for the film containing 4% castor oil. The reason is that by adding oil

to the film-forming solution, the solid content of the final coating

increases, because castor oil enters the CMC matrix, which results in an

increase in thickness. Same result have been reported by

Shojaee-Aliabadi et al. [47].

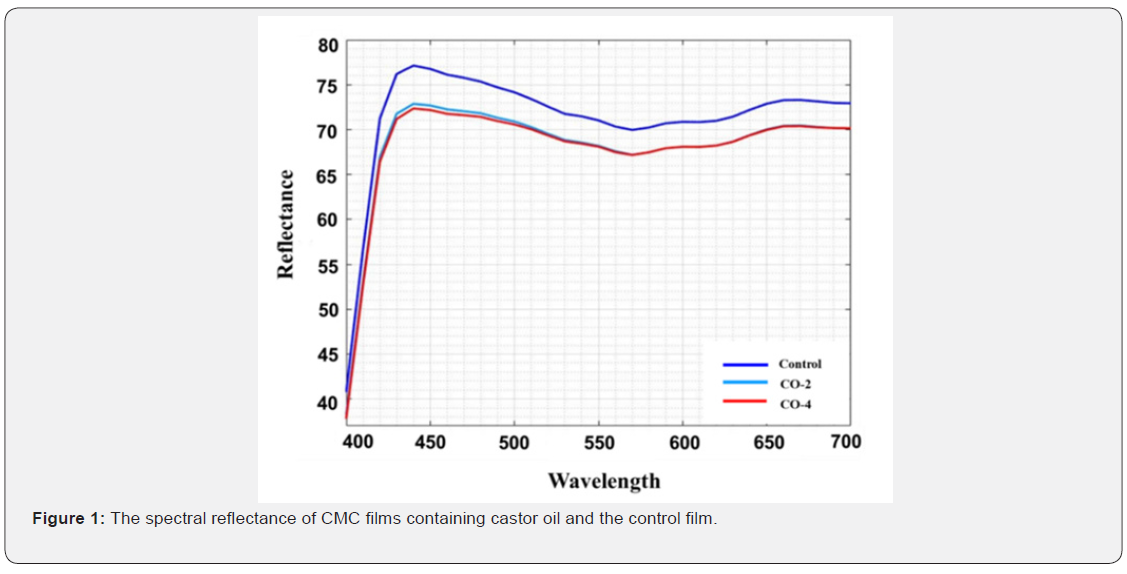

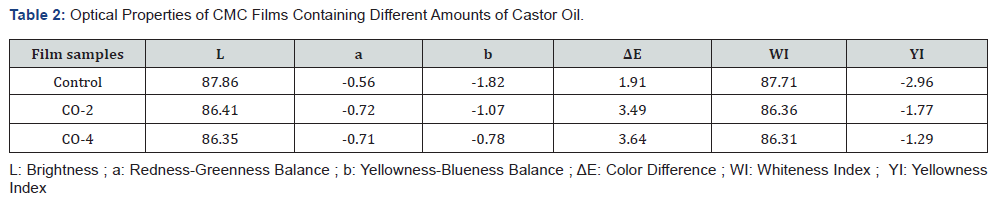

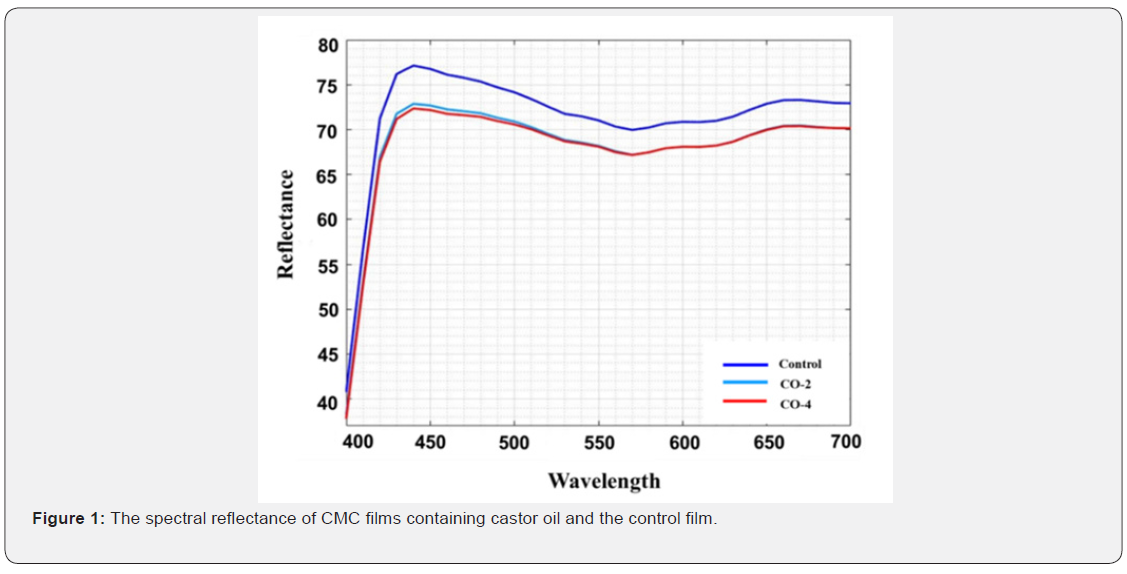

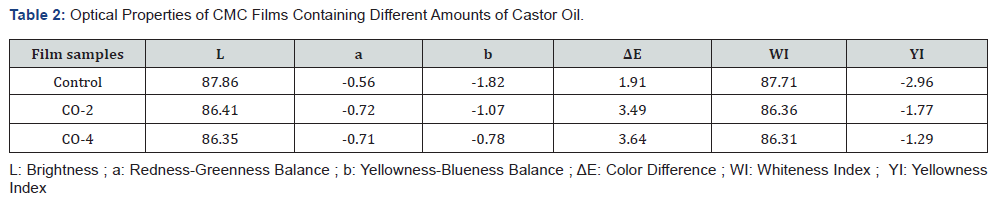

Optical properties or appearance is an important

factor of edible coatings and films as they affect the acceptancy of a

product by the consumers. The least expectation from a coating is to

maintain the appearance of the product if cannot improve it. The CIE

Lab, color difference (ΔE), whiteness index (WI) and yellowness index

(YI) values used to describe the optical properties are given in Table

2. The spectral reflectance curves of the samples are also shown in

Figure 1. As illustrated, the control film had the highest area under

the curve and therefore the highest brightness. The L value (brightness)

of the samples decreased slightly with increasing oil content. In

addition, the yellowness index of the specimens increased marginally

with increasing oil content in the film structure, which could be due to

the absorption of light by castor oil at low wavelengths. For the same

reason, the color difference of the samples increased moderately with

the addition of oil to the film (the color difference between the CO-2

and CO-4 samples having different oil content was not significant).

Finally, the whiteness index of the samples decreased slightly with the

addition of oil to the system. The presence of castor oil and increasing

the amount of it reduced the transparency of the film to some

negligible degree. The reason is that by adding oil to the film forming

solution, which is a water-insoluble fraction, the system becomes an

emulsion, resulting in a decrease in the transparency of the film

relative to the oil-free sample [48]. Overall, the addition of castor

oil to CMC films had no major negative effects on their appearance.

Moisture content of films is an important factor in

determining coatings quality. High moisture content can provide an ideal

environment for the growth of microorganisms and cause deterioration

during long storage periods. The MC also helps edible films to melt in

mouth when eaten [2]. The MC of each specimen is reported in Table 1. As

can be seen, samples containing castor oil had a lower moisture content

than the control film, and the MC decreases with increasing oil content

from 2% to 4%. The reason for this decrease can be mainly attributed to

the increased hydrophobicity of the films due to the increased oil

content. In addition to increasing hydrophobicity, the interaction

between castor oil and the hydroxyl groups present in the CMC impedes

water absorption by these groups, thereby reducing the amount of water

in the film. Similar results were found by previous studies [47,49].

Moisture content of a film can also affect its

solubility in water. The higher the moisture content of the film, the

greater the solubility in water. The water solubility of each film

sample is reported in Table 1. As shown in the diagram, the CMC film

containing no castor oil (control sample) is completely soluble in

water. The solubility in water decreased with increasing castor oil

concentration in samples due to the high amount of hydrophobicity in the

film matrix and preventing CMC hydroxyl groups from absorbing water.

The lowest water solubility was observed in CO-4 sample containing 4%

castor oil in its structure.

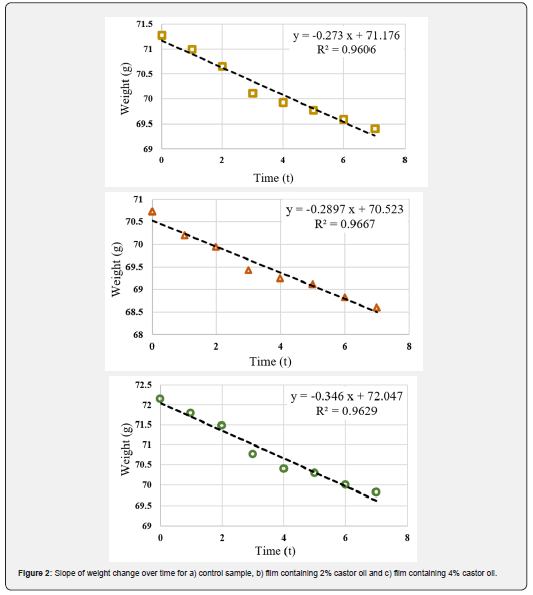

WVP is an important factor to investigate the

performance of edible films and coatings and can be influenced by

characteristics such as film integrity, hydrophobic ratio and film

thickness [50]. Knowing WVP of the film is very helpful for preventing

the mass transfer from food to the surrounding environment and therefore

extending the shelf life of the product. The values of G/t, which is

the slope of the weight change curve over time of the samples, are shown

in Figure 2. Using these slopes, the WVP values were calculated for the

samples (Table 1). It is observed that with increasing oil content, the

slope of the curve increased, resulting in a higher WVP. The film

containing 4% oil shows the highest amount of WVP. While the common

expectation is that increasing oil content would decrease the

permeability of the samples due to the increased hydrophobicity of the

films, the exact opposite result has been achieved. This could be due to

the fact that the increase in castor oil concentration in CMC films,

besides increasing the hydrophobicity ratio, had a negative effect on

the cohesion of the film matrix. The weakening of the cohesion forces in

the matrix accelerates the transfer phenomenon and ultimately increased

the water vapor permeability. Furthermore, castor oil also has a

softening effect similar to glycerol. This makes the movement of polymer

chains in the film easier, which increases permeability. Similar result

was observed in the work of Dashipour et al. [49].

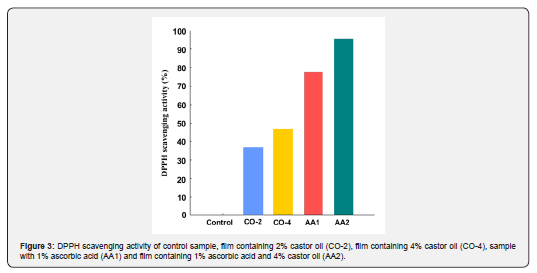

The ability of an edible coating to prevent foods

from oxidation is an important factor in determining the coating's

performance to extend the shelf life of the product. The higher the

antioxidant activity of the coating, the better its function in

protecting the food. In this study, the antioxidant activity of the

samples was measured by DPPH scavenging activity method, and the results

are shown in Figure 3. As expected, the control film showed no

antioxidant activity, as there is no compound in its structure capable

of radical absorption. The amount of antioxidant activity in

oil-containing films is significantly higher than that of control

sample. By increasing the oil concentration from 2% to 4%, the

scavenging activity of the film also increased and reached 46.3%, which

is desirable. The antioxidant activity of films containing just castor

oil was lower than that of ascorbic acid containing samples. The highest

scavenging activity was for AA2 sample, which had both castor oil and

ascorbic acid (95.4%). The radical scavenging activity of the

oil-containing specimens results from the unsaturated double bands

present in castor oil structure. These double bands become saturated by

absorbing free radicals; therefore, prevent the product from oxidizing.

Characteristics of edible films such as tensile

strength (TS), elastic modulus (EM) and elongation at break (EB) are

very important in coatings and packaging and can be helpful to predict

coatings performance [51]. Table 1 shows the TS, EM and EB values of

samples. As illustrated, the tensile strength of the control sample was

10.14 MPa, which decreased significantly with increasing oil content and

reached 3.43 MPa in CO-4 film. Similarly, the elastic modulus of the

films decreased with increasing castor oil from 76.91 MPa to 27.75 MPa.

On the other hand, with increasing castor oil concentration, the

flexibility of the films improved and therefore their elongation at

break increased from 24.81% for control sample to 49.08% for CO-4

sample. This can be due to the fact that the addition of castor oil

created a heterogeneous film, which results in decreasing mechanical

strength and increasing flexibility [52]. In addition, as mentioned

earlier, castor oil has some level of softening property. Therefore, its

molecules can be placed between CMC chains and facilitate their

movements and as a result increased the films’ flexibility, desirably.

Determination of thermal properties, especially glass

transition temperature, is very effective in evaluating the performance

of edible films and coatings. If the glass transition temperature of

the film is much higher than the ambient temperature, the film would be

very brittle, but it would have low permeability. However, if the Tg

is lower than the ambient temperature, the permeability would be very

high and the film would be very soft and flexible, which will not

provide the proper mechanical protection for the product. As a result,

if the glass transition temperature of the films is slightly above

ambient temperature (close to ambient temperature), it will be in a

desirable range of permeability and mechanical strength [46]. Therefore,

if castor oil could reduce the Tg and Tm of the specimens, it will be

considered a beneficial effect. Thermal diagram of the samples obtained

by performing DSC experiment and is shown in Figure 4. As shown in the

diagrams, in the temperature range of 208℃ to 211°C there are large and

endothermic peaks, which could be attributed to the melting temperature

of the CMC matrix. The Tm of the control sample is 210.99°C, and with

increasing castor oil content to 4% (CO-4), the Tm reached 208.39°C. As

presented, no glass transition temperature was observed in the samples

due to the low sensitivity of the test equipment.

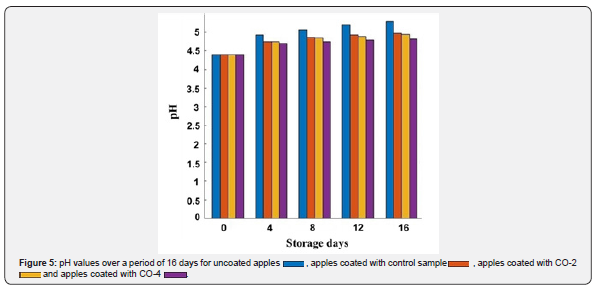

The microbial growth in the food produces

nitrogen-containing compounds that increase the pH of the product [53].

The coating should prevent this increase in pH by restraining the

microbial growth. The better the coating performs in this matter, the

lower the pH increases and the longer the shelf life of the product will

be. The pH values of control and coated apples were measured over 16

days, which are represented in Figure 5. As can be seen, the highest pH

increase was for uncoated apples and the lowest increase was for apples

with CO-4 coating. In general, coatings (especially the ones with castor

oil) were successful in preventing pH increase and their pH was lower

than non-coated apples after 16 days. This result shows that CMC-based

coatings containing castor oil prevented pH value from increasing.

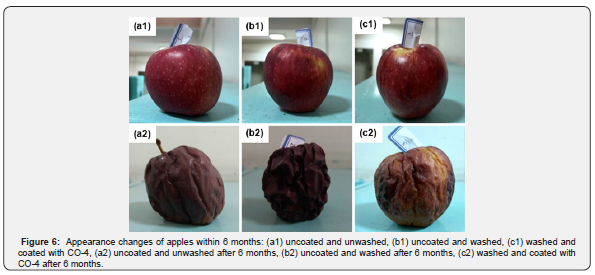

As mentioned earlier, one of the causes of food

deterioration is time. Nowadays, the process of preparing foods until

they are ready for consumers’ use takes a considerable amount of time.

During this time-consuming process, foods could undergo water loss and

deterioration. Therefore, the performance of edible coatings over time

is very important. Figure 6 shows the changes of apples after being

exposed to ambient temperature for 6 months. Although the coated apple

(Figure 6, c2) was also suffered from high deterioration, it had less

water loss and discoloration than the other two apples, which had no

coating. The coated apple also had a much better physical state and was

more firm and less wrinkled than the other two.

The presence of castor oil in the film forming

solution increased the thickness of the resulting CMC films, but due to

its hydrophobic nature, reduced the moisture content and water

solubility of the films. The addition of castor oil in carboxymethyl

cellulose films resulted in higher permeability due to the weakening of

cohesion forces in CMC matrix and softening properties of the oil. The

mechanical strength of the films was also weakened for the same reason.

As the oil content increased, the color difference and yellowness index

of the films increased, and the whiteness index decreased slightly. Due

to the presence of unsaturated double bonds in the castor oil structure,

this oil had the ability of radical absorption and therefore

antioxidant activity. Addition of castor oil had no significant effect

on the thermal properties of the carboxymethyl cellulose films and

reduced the melting temperature of the samples by 3°C. The coatings

prevented the early deterioration of apples and reduced the pH

increasing rate by preventing the growth and activity of the

microorganisms.

Click here: https://juniperpublishers.com/index.php

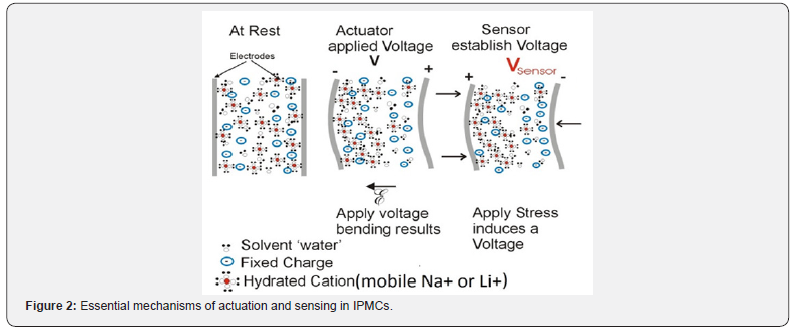

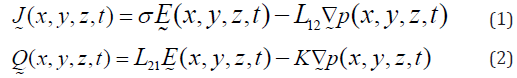

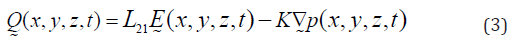

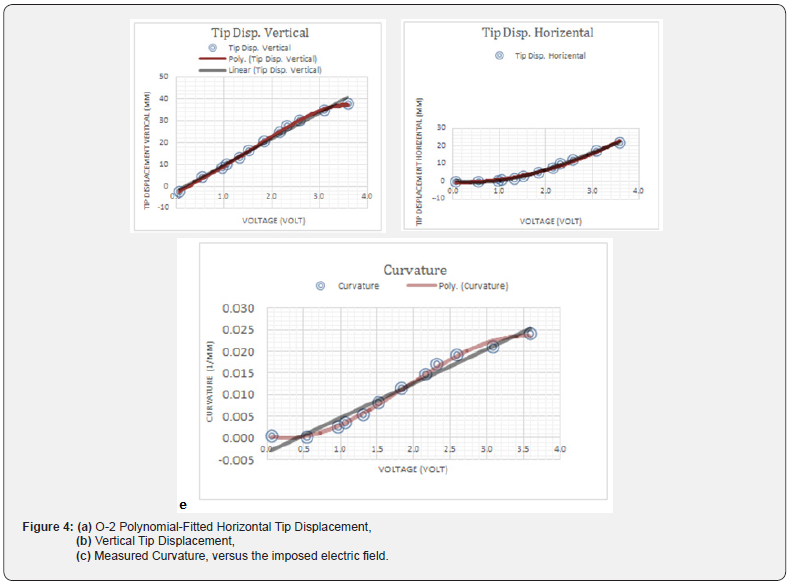

. The resulting equation has the concise form

of

. The resulting equation has the concise form

of

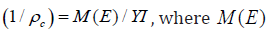

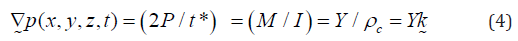

is the local induced

bending moment and is a function of the imposed electric field

E, Y is the Young’s modulus (elastic stiffness) of the strip which

is a function of the hydration H of the ionic polymer metal

nanocomposite and I is the moment of inertia of the strip. Note

that locally M(E) is related to the pressure gradient such that in a

simplified scalar format [15]:

is the local induced

bending moment and is a function of the imposed electric field

E, Y is the Young’s modulus (elastic stiffness) of the strip which

is a function of the hydration H of the ionic polymer metal

nanocomposite and I is the moment of inertia of the strip. Note

that locally M(E) is related to the pressure gradient such that in a

simplified scalar format [15]:

is related to the imposed

electric field E

is related to the imposed

electric field E  Based on this simplified

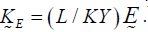

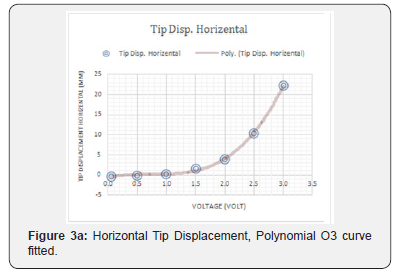

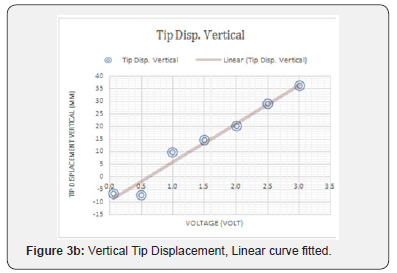

model the tip bending deflection δmax of an IPMC strip of length lg

can be shown to be almost linearly related to the imposed electric

field. The experimental deformation characteristics of IPMCs are

clearly consistent with the above predictions obtained by the

above linear irreversible thermodynamics formulation which

is also consistent with the above equation in the steady state

conditions. Note also that the value of the Onsager coefficient L

has been estimated to be of the order of 10-8m2/V-s [20-24]. Other

parameters have been experimentally measured to be K~10-

18m2/CP, σ ~1A/mV or S/m. On the other hand one may consider

charge transport modeling of actuation and sensing. The reader is

referred to Bahramzadeh and Shahinpoor [20-24] and Shahinpoor

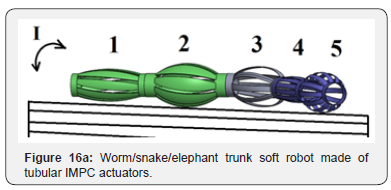

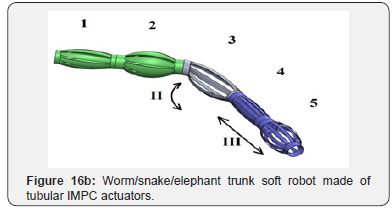

[22-24] for such Poisson-Nernst-Planck equations. Similar to poly (ethylene-co-methacrylic acid) metal composite, member of

the electroactive polymer can be introduced as biomimetic soft

robotic polymer [28-32].

Based on this simplified

model the tip bending deflection δmax of an IPMC strip of length lg

can be shown to be almost linearly related to the imposed electric

field. The experimental deformation characteristics of IPMCs are

clearly consistent with the above predictions obtained by the

above linear irreversible thermodynamics formulation which

is also consistent with the above equation in the steady state

conditions. Note also that the value of the Onsager coefficient L

has been estimated to be of the order of 10-8m2/V-s [20-24]. Other

parameters have been experimentally measured to be K~10-

18m2/CP, σ ~1A/mV or S/m. On the other hand one may consider

charge transport modeling of actuation and sensing. The reader is

referred to Bahramzadeh and Shahinpoor [20-24] and Shahinpoor

[22-24] for such Poisson-Nernst-Planck equations. Similar to poly (ethylene-co-methacrylic acid) metal composite, member of

the electroactive polymer can be introduced as biomimetic soft

robotic polymer [28-32].

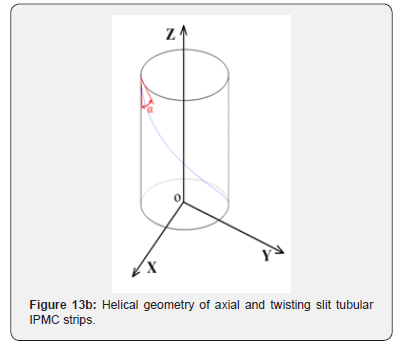

torsion

of a helix is given by

torsion

of a helix is given by