Forensic Sciences & Criminal Investigation - Juniper Publishers

Abstract

Cut damage due to Sharp objects on different types of clothing is occasionally referred for analysis to forensic laboratories to correlate crime with criminal and/or crime scene in different kinds of cases related to stabbing, sexual assaults, robbery etc. Such examination is essential to help the investigation & to corroborate even the events of crime. Present study is focused on the correlation of the damaged clothing with the specific object/ weapon which was used and caused the damage. The end areas of the cutting damage on clothing are the most important factors for the correlation of clothing with used weapon(s) therefore morphological characteristics of the fiber-end of damaged clothing were examined using scanning electron microscope by observing different features e.g., frayed ends, fiber distortion etc. It was noticed that differentiation can be made between cut caused by razor, Paring knife, Lazer and/or Steak Knife by SEM studies.

Keywords: Clothing damage; Fiber; Knife; Scanning electron microscope; Weapon

Introduction

Examination of damaged clothing is an integral part of crime investigation and is carried out in various types of criminal cases including stabbing, sexual assaults, robbery etc. The clothing related to such types of cases can be used to corroborate the events of crime as clothing damage analysis has potential to correlate crime with criminal and crime scene. Moreover, it is an established fact that the examination of clothing not only provides evidence with person or locations but explains as to what happened during the crime event. The examination of fabric damage is a common task for the forensic scientist, predominantly in cases of homicide and alleged assault. The damage on clothing can occur because of the four major effects- Physical, mechanical, chemical, and thermal effect. The physical and mechanical effect includes the damage by sharp weapon, blunt object, abrasion or frictional force, mechanical strain (pulling the textile by great force) etc. [1]. Different methods for the analysis of damage to clothing-cuts and tears have been reported [2-5]. The present study is focused on Scanning Electron Microscopic Studies on Cut damage due to Sharp objects on Cotton Clothes.

Materials and Methods

Preparation of simulated samples

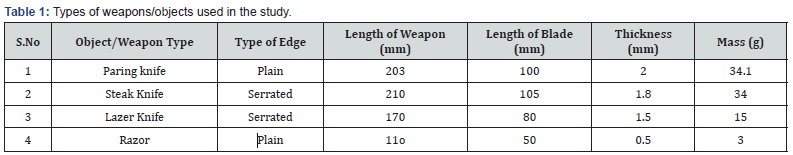

The clothing samples selected for this study consisted of cotton fabric. Cotton clothes specimens were mounted on a round wooden cloth holder to ensure proper stretch. Four different kinds of objects/weapon like Paring knife, Steak knife, laser knife and razor were used to make simulated samples. Each cloth sample was fixed over a holder and cut were made using the object. Paring knife had a blunt upper edge and a plain sharp lower edge (length = 203mm, blade = 100mm, thickness =2mm and mass= 34.1g). The Steak knife had a clip shaped upper edge and a scalloped lower edge with serrated blades (length=210mm, blade length = 105mm, thickness =1.8mm, and mass =34.0g). The laser knife was 170mm long, with a blade length of 80 mm and a mass of 15.0 g. It was thin at spine and very thin behind the edge. The razor used had a flat cutting edge with pointed tip. (Length= 110mm, blade length= 50mm, thickness =0.5mm and mass =3.0g) Table 1.

Examination of samples

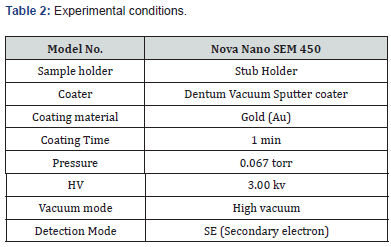

The examination of damaged clothes was designed to three level observation, morphological level, yarn level and fiber level. Fiber is a basic raw material (natural or man-made) used to make yarn and yarn is a continuous length of interlocked fibers. Initially cut portions/ends were examined under compound microscope and the results obtained are given in image 1-5. No distinct features could be noticed therefore these samples were subjected to scanning electron microscopic (Nova NanoSem 450) examination. This microscope is a modern field-emission scanning electron microscope with 1nm ultimate resolution, large sample chamber with advanced motorized stage and navigation supported by an in-chamber camera. High- and low-vacuum operations can be possible with this instrument. Samples were placed on stub-holder and were kept inside Denton Vacuum (Sputter Coater). Vacuum was generated at 0.067 Torr and Coating was done using Au metal [6] Table 2.

Result and Discussion

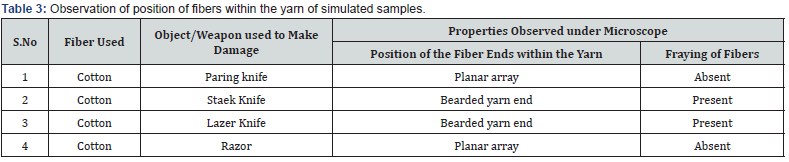

In the present study, two parameters are explored to differentiate the damage of clothing by different sharp objects. First parameter is observing the Position of the fiber ends within the yarn (planar array or bearded yarn ends). Planar array is where a clean-cut leaf all the fiber ends in the same plane of the yarn and a bearded yarn occurs during tearing where the fibers break at different positions in the yarn. Second parameter explored in this study was the fraying of the damaged fiber (Figure 1-4). (Fraying refers to the extent of the displacement of the yarn out of the weave). In case of damage due to paring knife, the fiber ends showed sharp cuts and margins were straight forming flat top with lip and the fibers were aligned in planar array with no fraying (Figure 5). In the case of damage due to razor, fiber end were found flat lip and loosely clustered and all ends of fibers terminating in similar plane, aligned in planar array. Fraying was absent in damage due to razor. (Figure 6). However, in damage due to steak knife and lazer knife, the damaged fiber ends exhibited “no clustering of fiber”. Fiber ends terminated in different planes with a random orientation and the fibers possessed bearded yarn end and significant fraying was also observed (Figure 7 & 8) Table 3.

Conclusion

Based on above observations, it is concluded that the SEM studies found to be a suitable technique to correlate weapon with the damage on clothing. However, the studies on the other types of clothing like rayon, polyester, silk, woolen etc. must be examined to establish the specificity of this technique.

To Know more about Forensic Sciences & Criminal Investigation

Click here: https://juniperpublishers.com/index.php

No comments:

Post a Comment