Mining Science & Technology - Juniper Publishers

Magnetizing reduction is an important pre-treatment

process used for low-grade iron ores which are difficult to upgrade by

conventional beneficiation techniques. In present study, magnetizing

reduction of a low-grade iron ore has been carried out followed by

magnetic separation of iron minerals to produce iron concentrate. A

potential process has been developed for magnetizing reduction of

hematite into magnetite with domestic lignite coal. The experiments were

carried out in Muffle furnace under controlled temperature conditions.

The main process variables such as particle size of ore, ore to coal

consumption ratio, reduction temperature and retention time were

investigated to determine the extent of magnetizing reduction. In second

step, reduced iron ore was subjected to low intensity magnetic

separation to recover iron values in the magnetic concentrate. A

single-factor variation method was applied in order to get the optimum

conditions of the process. The results of bench scale experimental study

showed that the maximum grade and recovery of iron concentrate was

achieved at ore size of 90-95% minus 200 mesh, ore to coal consumption

ratio of 1: 0.25, the reduction temperature of 700°C and the retention

time of about 60 minutes. The ore containing 33.95% Fe was upgraded to a

concentrate assaying 64.13% Fe with 83.70% recovery. The iron

concentrate produced meets the specifications of metallurgical grade and

is suitable for use as a feed for blast furnace and other direct

reduction methods.

Keywords:

Low-grade iron ore; Beneficiation; Magnetizing reduction; Low intensity

magnetic separation; Iron concentrate; Hematite; Magnetite;

Metallurgical grade; Recovery

Conventionally iron and steel is produced by the

reduction of high-grade iron ores in a blast furnace. About 80% of the

world’s iron making is achieved through the blast furnace process and

rest by different direct reduction (DR) processes. The role of

high-quality iron ore and concentrate as a raw material is very critical

to get the best quality iron and steel [1]. The high-grade iron ores or

concentrate should contain at least 60% iron (Fe) content with maximum

up to 7% silica (SiO2) content [2]. The product of blast

furnace is a pig iron which is then converted into steel by various

techniques [3]. The quality of raw materials used in blast furnace plays

an important role in steelmaking process.

The iron ores available at different areas of

Pakistan are generally low-grade with high silica content. These ores as

such cannot be utilized to produce iron and steel by conventional blast

furnace technique or DRI processes. The first step in iron making

involves the separation of iron minerals from low-grade iron ores. There

are three basic methods for separation of iron minerals i.e., magnetic

separation, froth flotation and gravity concentration [4]. The iron

concentrate produced by any processing method is used for producing iron

metal either by blast furnace or direct reduction methods [5]. The fine

iron concentrate is to be palletized or sintered for both routes [6].

Magnetic separation is most used to separate natural

magnetic iron ore (magnetite) from a variety of less magnetic or

nonmagnetic material [7]. Magnetizing reduction is one of the most

effective unit operations in the treatment of low-grade iron ores

specially those which are poorly responsive to conventional

beneficiation techniques such as froth flotation, gravity separation and

magnetic separation [8,9]. It involves the conversion of feebly

magnetic iron minerals in the ore to the strongly magnetic form by

subjecting the ore to a reducing atmosphere at elevated temperatures.

The resulting artificial magnetite is strongly magnetic and can be

separated from the non-magnetic gangue by low-intensity magnetic

separation. Many weakly magnetic minerals can be converted to more

strongly magnetic compounds by magnetizing reduction processes [10-12].

Geological Survey of Pakistan (GSP) during regional

survey in 1989 discovered iron ore deposits near Chiniot town and

adjoining areas such as Rajoa, Chak Jhumra, Wad Syedan, Ghutti Syedan,

Shaheen Abad, Sargodha and Sangla Hills etc. Subsequently, the Punjab

Mineral Development Corporation (PUNJMIN) carried out detailed

exploration in year 2005 to 2007. As a result of exploration work,

anomalous zones containing iron ore and other associated metallic

minerals have been confirmed in Chiniot with strong indications in

Rajoa. The other metallic mineral resources including copper, gold,

nickel, cobalt etc. are also found in the underlying sulphide zone

associated with the iron ore. Around 150 million tons of good quality

iron ore reserves had been identified in Chiniot. The field survey based

on the cores recovered from several drill holes of the ore body has

shown that the ore occurs in bands ranging from one meter to several

meters in thickness. The Chiniot iron ore is predominantly oxide ore

containing variable amount of hematite and magnetite as principal iron

bearing minerals. The ore is massive, low to medium grade containing as

low as 30 Fe2O3 to as high as 70 Fe2O3. The resources are buried under alluvium, aquifers and hosted in the subsurface volcanogenic rocks [13].

With ever rising steel prices, the local

manufacturing of steel based on indigenous reserves of iron-ore is

critical. The main problems in utilization of indigenous iron ore is

up-gradation and beneficiation of available resources. Development of

domestic technologies for utilization of indigenous iron ore will not

only reduce the dependence of steel production on imported raw material,

but it will also result in lowering the steel price. Present

beneficiation studies are oriented towards exploring the possibilities

of upgrading Chiniot iron ore to produce iron concentrate for

utilization as a feed in conventional blast furnace or direct reduction

method to produce iron and steel.

The core samples of seven drill holes of Chiniot iron

ore weighing about 40kg were received for beneficiation studies. The

drill cores were crushed in laboratory jaw crusher (set at 20mm)

followed by roll crusher (set at 5mm) for size reduction. Riffling

technique of sampling was used to prepare the head sample for chemical

analysis. The head sample was pulverized to 100% minus 200 mesh (74µm)

in disc pulverizer (Denver, USA). The crushed ore was split into 1kg

samples and kept in plastic zipper bags for R& D work. These ore

samples were ground in rod mill for magnetizing reduction and magnetic

separation tests.

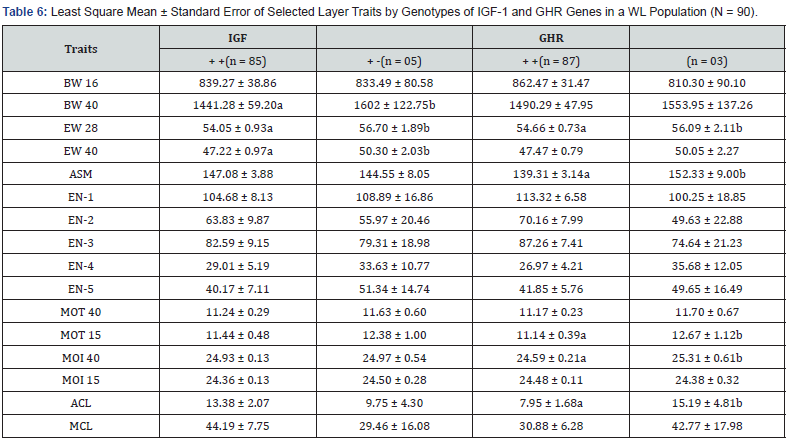

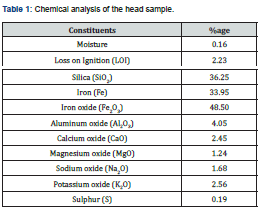

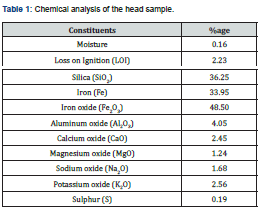

The chemical analysis of head sample of iron ore

originating from Chiniot area was carried out by standard wet analytical

methods and atomic absorption spectrometer. Ore was fused with sodium

carbonate and sample solution was made in dilute HCl. Silica, alumina,

and sulphur were determined gravimetrically while iron was determined by

oxidation reduction titration. Calcium and magnesium were determined by

complexometric titration using standard solution of EDTA. Sodium and

potassium were determined by flame photometer (PFP7, Jenway Limited,

England). Loss on ignition (LOI) was determined at 1000oC. The complete chemical analysis of head sample of Chiniot iron ore is shown in Table 1.

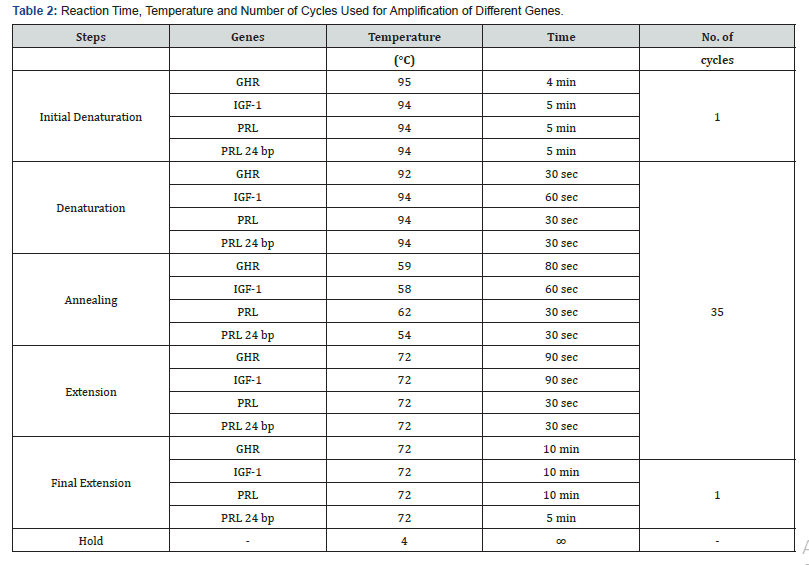

Magnetizing reduction tests were carried out on

ground ore using locally available lignite to sub-bituminous coal used

as reducing agent. The pulverized coal sample used has 2.45% moisture,

37.79% ash content, 35.20% fixed carbon, 24.56% volatile matter, 5.86%

sulphur and its gross calorific value of coal was 6150 Btu/lb. Known

weight and sizes of ground ore and coal were mixed in different

composition. These were placed in porcelain crucibles (100ml capacity)

and covered with lid. These were heated by gradually by raising the

temperature with increment of 100°C per 30 min in electric (muffle)

furnace to desired temperature and then maintaining it for magnetizing

reduction of hematite into magnetite. The crucibles were removed after

keeping them at different temperature for different time interval. Runs

were conducted on 50g ore charged. The ore to coal ratio was studied

from 1: 0.1 to 1: 0.30, the reduction temperature was ranged from 500 to

800°C, the residence time was varied between 30 min to 120 min and the

particle size of ore was varied from 90-95% passing 100 mesh to 250

mesh.

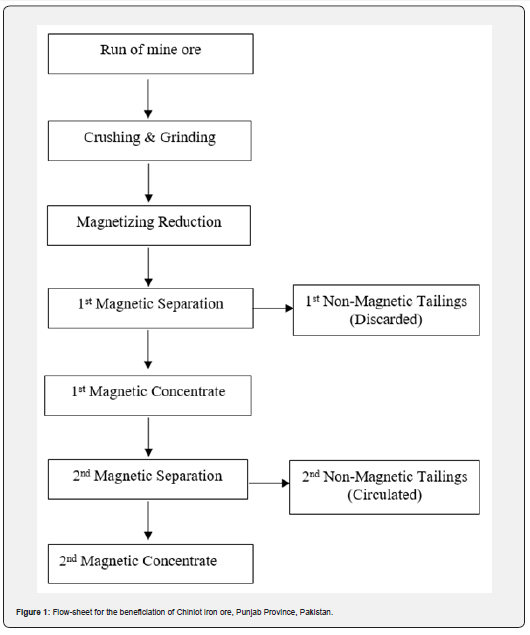

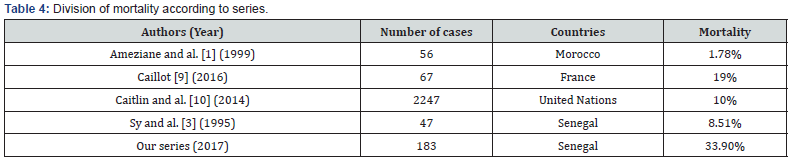

The reduced ore (feed) was subjected to wet low

intensity rotary drum magnetic separator (Sala, Italy) having permanent

magnets for separation of magnetic minerals form associated gangue

minerals. The drum dimensions were 200 mm dia × 100 mm width. The

intensity of magnetic field (strength) was set at 1000 gauss. Tests were

conducted at feed rate of 10-15 kg/hr, wash water flow rate of 20-25

l/hr and number of operations (passes) 2. The magnetic (concentrate) and

non- magnetic (tailings) portions were collected separately, dewatered

and oven dried. The dried concentrate and tailings were weighed and

chemically analyzed for total iron content. The results of magnetic

separation tests are given in Table 2. The flowsheet developed for the

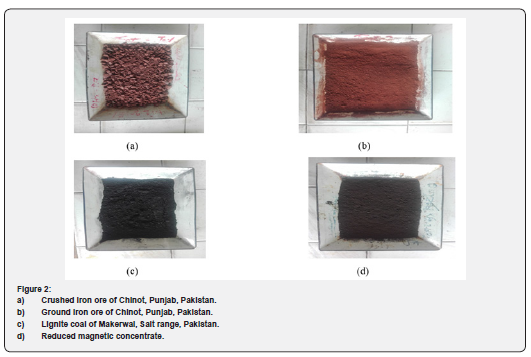

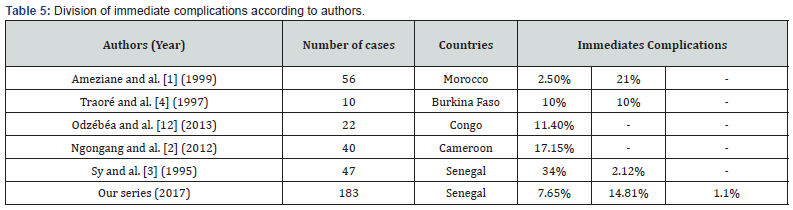

process is given in Figure 1. The images of the crushed sample, ground

head sample, ground lignite coal and reduced magnetic concentrate are

shown in Figure 2.

The chemical analysis of head sample (Table 1)

indicates that ore contains 33.95% total Fe. The main impurity is silica

being 36.25% which is more than the permissible limit required for iron

and steel production. The level of other impurities is not very high

except sodium oxide and potassium oxide. These impurities are present

due to the occurrence of cerecite and feldspar in the ore. The iron

mineralization varies from massive over 70% Fe2O3 through medium 50% Fe2O3 to low grade 30% Fe2O3.

The iron minerals occur as hematite and magnetite. The hematite to

magnetite ratio varied from 1. 3:1 to 2.0:1. The ore is hard, tough and

compact. As hematite is a weekly paramagnetic mineral, while the other

minerals present in the ore are diamagnetic in nature. It was decided,

in this perspective, to convert hematite into magnetite followed by low

intensity magnetic separation technique which has the potential to

recover the iron values and reduce the siliceous gangue minerals

effectively [14].

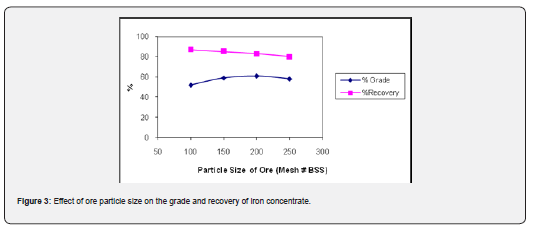

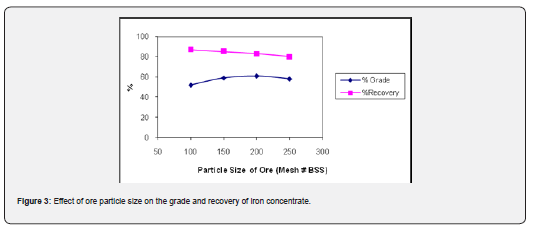

The particle sizes worked at were almost 90-95% passing 100 mesh (150µm), 150 mesh (100µm), 200 mesh (75µm) and 250 mesh (65µm)

for magnetizing reduction study keeping other factors constant. The

results of beneficiation tests (Figure 3) showed that although some

up-gradation has been affected at coarse size. However, the concentrates

were high in silica content showing thereby that it is locked within

iron oxide particles. It was thought essential to grind the ores to

finer size. It was observed that the samples ground to 90-95% passing

200 mesh responded most favorably to magnetic separation. The

magnetizing reduction followed by magnetic separation results showed

that as the particle size of feed was reduced from 90-95% passing 100

mesh through 150 mesh to 200 mesh, the grade was improved gradually from

52.45% Fe through 58.90% Fe to 61.05% Fe with slight decrease in

recovery of total iron content of concentrate from 87.12% through 85.03%

to 84.72%. However, after that both grade (58.23%) and recovery

(80.31%) were dropped sharply probably due to finer particle size of

ore.

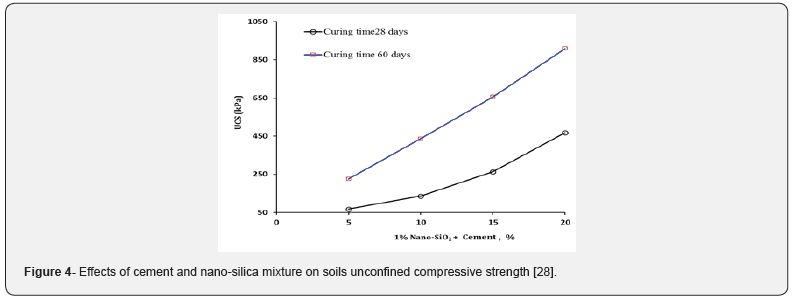

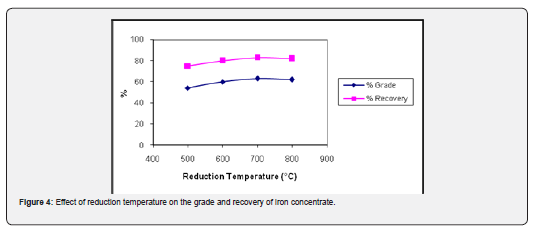

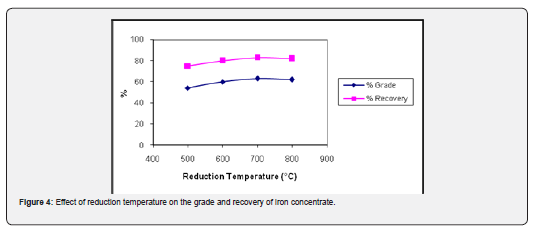

Temperature has a significant effect on magnetizing

reduction process. It plays an important role in the phase change of

hematite and limonite during magnetizing reduction [15]. The iron ore

samples of 90-95% passing 200 mesh size were subjected to magnetizing

reduction with excess of coal (30%) at 500°C, 600°C, 700°C and 800°C for

60 min to study the effect temperature on the magnetizing reduction of

iron ore. The reduced samples were separated, and magnetic fractions

were subjected to chemical analysis to determine the iron content. The

results obtained are shown in Figure 4. It is clear from this figure

that iron grade and recovery in the magnetic fraction exhibits a gradual

increase with rise in reduction temperature and reaches at maximum

value 62.31% Fe with 82.75% recovery at the onset of reduction

temperature of 700°C and then slowly declines. It is since as the

temperature is raised between 200 to 700°C the carbon in the form of

coal burns to produce carbon monoxide.

2 C(s) + O2(g) → 2 CO(g)

The hot carbon monoxide is the reducing agent for the iron ore and reacts with the hematite iron oxide Fe2O3 (III) to produce magnetite iron oxide Fe3O4 (II) and carbon dioxide.

3 Fe2O3(s) + CO(g) → 2 Fe3O4(s) + CO2(g)

The hot carbon dioxide formed in this process is re-reduced to carbon monoxide by further reaction with the coal.

C(s) + CO2(g) → 2 CO (g)

As the temperature is further increased beyond 700°C,

most of the coal is consumed away and some of freshly converted

magnetite present on the surface is re-oxidized to hematite by air which

lowers the recovery rate during magnetic separation [16].

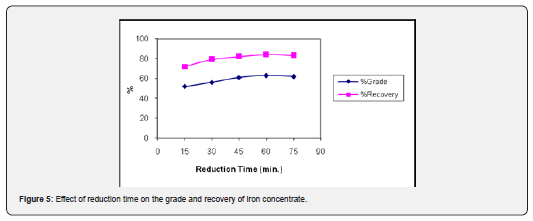

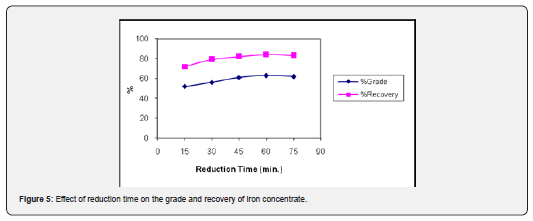

The effect of reduction time was investigated by

varying it from 15 to 75 minutes with increment of 15 min and keeping

other parameters constant at feed size of 90-95% passing 200 mesh size,

the reduction temperature of 700°C and ore to coal ratio of 1: 0.30. It

is obvious from the result (Figure 5) that iron grade and recovery in

the magnetic fraction increases gradually in the beginning and then

represents a sharp increase (63.45% Fe with 82.93%) at the onset of

reduction time of 60min and then decreases with increase in reduction

time. It is observed that when the reduction time was extended from

60min, the magnetic properties of the reduced ore were decreased (Figure

2). The prolonged reduction time results in excessive reduction and

waste of energy resources. Also, when the reduction time is less than

60min, insufficient reduction occurs leading to lower metallurgical

results [17].

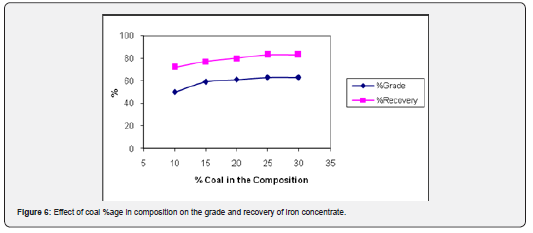

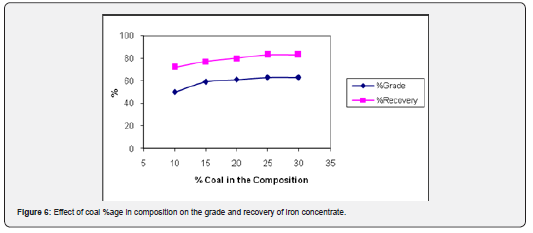

The effect of coal as reducing agent on the reduction

of hematite to magnetite was investigated by varying the ratio of ore

to coal from 1: 0.10 to 1: 0.30 in the charge at a temperature of 700°C

for 60 min using the particle size of 90-95% minus 200 mesh size. The

coal carbon burns as the temperature is increased and reducing gases

such as carbon monoxide are formed that initiate the reduction of

hematite into magnetite. As a result, this reaction, conversion of

hematite into magnetite takes place [18,19]. The results obtained

(Figure 6) show that the metallurgical performance (grade and recovery)

of magnetizing reduction is improved and reaches its highest value of

64.13% Fe with 83.70% recovery as the ratio of coal in the ore was

increased up to 1: 0.25 in the charge. Further increase seems to be

insignificant as it does not improve the results.

Low-intensity magnetic separators use magnetic fields

between 1,000 and 3,000 gausses [20]. Low-intensity magnetic separation

techniques are normally used on magnetite ore as an inexpensive and

effective separation method. This method is used to capture only highly

magnetic material, such as magnetite. High-intensity separators employ

fields as strong as 20,000 gausses. This method is used to separate

weakly magnetic iron minerals, such as hematite, ilmenite, rutile,

siderite, chromite, wolframite, pyrrhotite, monazite from non-magnetic

or less magnetic gangue material [21-25]. The preliminary direct

low-intensity magnetic separation tests showed that ore contain mainly

hematite as iron bearing mineral as only 25 to 35% of total iron (Fe)

corresponding to magnetite was recovered by low-intensity magnetic

separation. Between 30 to 35% of all the iron units being beneficiated

are lost to tailings because hematite is only weakly magnetic.

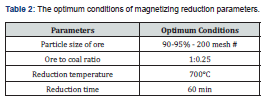

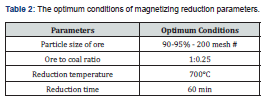

The optimum conditions of magnetizing reduction

parameters (Table 2) depict that when the crude ore grade is 33.95% Fe,

the mass percent of pulverized coal as reducing agent is 25%, reduction

temperature is 700℃, reduction time is 60 min and particle size is

90-95% passing 200 mesh # (0.074mm). The iron concentrate can be got

after a low-intensity magnetic separation, whose grade is 64.13% Fe and

recovery is 83.70%.

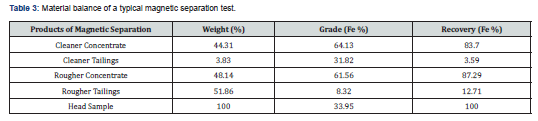

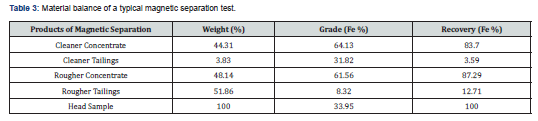

The metallurgical balance (Table 3) shows that Chinot

iron ore is amenable to beneficiation using low-intensity magnetic

separation after magnetizing reduction technique. The magnetizing

reduction trials of iron ore followed by magnetic separation has

indicated that the ore has been concentrated to 64.13% Fe grade with

83.70% recovery starting from a crude ore assaying 33.95% Fe. The silica

content is greatly affected by the magnetizing reduction treatment

where it decreases from 36.25% in the ore to 4.38% in the magnetic

portion. Magnetizing-reduction has been found an efficient technique for

the recovery of values from this ore with acceptable recovery. The

developed process is low energy consuming, cost effective and

convenient.

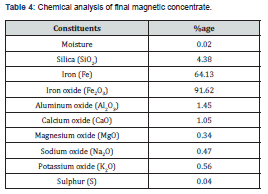

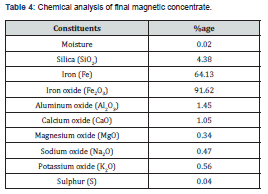

The chemical analysis of final concentrate (Table 4)

reveals that after beneficiation, iron content (Fe) has been increased

significantly from 33.95% to 64.13% with decrease in amount of silica

(SiO2) from 36.25% to 4.38%. The prepared iron concentrate

having iron and silica in this range is considered suitable for the

preparation of iron and steel by Blast Furnace and alternative iron

making processes such as SL/RN, Krupp-Renn, Midrex, Corex, Hyl, Romelt,

Hismelt, Ausmelt, Dios etc. [26]. There is a quite variation in

selection of feed for different processes. The reducing agents may be

gas or solid or both fuels. The charge may be lumps, screen size, fines,

pellets, sinter, agglomerate or briquettes. The quality of iron ore or

concentrate is key parameter in the selection of process. Some rotary

kiln processes such as (Krupp-Renn/ SL/RN) can use lower grade iron ores

(Fe 50%) while other process require high grade iron ore having more

than 65% Fe content such as Midrex process. The product of DR processes

is sponge iron which is converted into steel [27].

The quality of high-grade iron ore or concentrate

made from low grade ore has a significant effect on the efficiency and

economy of blast furnace. The various impurities present in iron ore in

the forms of silica, alumina, alkalis, phosphorus and sulphur behave

differently during smelting and adversely affects the performance and

economy of blast furnaces. The presence of phosphorus and sulphur

increases surface cracking during steel processing. The acceptable

levels of phosphorous (P) vary from 0.08 to 0.14%, while sulphur (S) is

up to 0.06% in hot metal. High alkali (Na2O & K2O)

contents lower the mechanical strength of coke and sinter, imbalance

the furnace operation, reduce the furnace productivity and damage the

lining. The desired levels of alkalis are 0.4% of hot metal. The

increase in silica (SiO2) content leads to the generation of

more siliceous slag with high viscosity, consumes more limestone or

dolomite. The desired level of silicon (Si) in the steel is 0.6%. High

alumina (Al2O3) decreases the fluidity of slag,

and more coke is required to increase the fluidity. It has been reported

that reduction of the alumina content in iron ore by 1% improves blast

furnace performance by 3%, reduces reduction degradation index (RDI) by 6

points, lowers the coke rate by 14 kg per ton of hot metal and

increases sinter productivity by 10-15%. The high iron (Fe) content and

low impurities contents in iron ore are highly desired in the blast

furnace operations and economy. Different steel plants have varied

quality requirements based on the techniques and process adopted.

Specifications of a typical iron ores required by steel plants for iron

making are as Fe 60-67%, SiO2 1-6%, and Al2O3

3- 4%. The values of these constituents in the iron concentrate

prepared from Chinot iron ore lies well within the acceptable limits

[28,29].

The results of the experimental study showed that the

quality of Chiniot iron ores can be greatly improved by subjecting to

magnetizing reduction followed by magnetic separation technique. A great

deal of impurities is removed, and the iron content is significantly

increased. The ore concentrate obtained is high-grade material suitable

for direct use as a feed to produce iron and steel in number of

processes. The results reported show that it is possible to upgrade low

grade iron ore of Chiniot area by magnetizing reduction followed by low

intensity dry magnetic separation technique to produce iron concentrates

of metallurgical grade with acceptable recovery. The SiO2

content was reduced remarkably from 36.25% to 4.38%. The iron contents

were upgraded significantly from 33.95% to 64.13% at recovery of 83.70%.

The final concentrate produced meets all the specifications of the

metallurgical grade iron concentrate and can be directly used to produce

iron and steel after palletizing. The advantage of this technique is

that it is easy to operate, less expensive and environment friendly.

To Know more about Mining Science & Technology

Click here: https://juniperpublishers.com/index.php