Material Science - Juniper Publishers

Abstract

In the recent decade, the driving range of pure EVs

with zero emission target has become a popular topic as the massive

battery requirement for longer distance travels means higher vehicle

cost and longer time of recharging periods. Stationary CPT charging

solutions could be an alternative to reduce EVs weight, size and energy

storage unit costs. Fortunately, with progressive success of low-power

CPT charging applications proposed to be commercially produced in the

past decade, hundreds of kilowatts level high-power CPT charging

techniques for EVs are more and more expected to be an optimally

suitable solution for recharging EV batteries, providing higher

propulsion and delivering continuously longer driving range in the next

generations of the EVs. The idea of deploying inductive coupling for EVs

has acquired a lot of attentions in the last decade due to the

contributions and advancements of power electronics, switching power

supply, semiconductors, microprocessors, electrochemistry, material

sciences, control technologies, electromagnetics and so on, despite many

challenges to be addressed including EV manufacturing integration with

CPT system under the chassis, infrastructure difficulties, system

maintenance on both vehicle and transmitting ground sides, actual CPT

performance with real-time coupling on real-world road. In order to

ensure the realization and enhance the sustainability in transportation

sector with the emerging CPT ideas, currently the stationary CPT

charging solutions based on inductive power transfer (IPT) have been

developed from laboratory level as a first step to the practical tests

of commercial realizations. In a few industrial fields nowadays, some of

the proposed CPT technologies with specific coupler coil designs have

been expected for real-world applications. This article presents a state

of the art of the CPT technologies and focuses on reviewing current

coil designs for high-power contactless energy transfer for EVs in the

literature.

Keywords:

Contactless power transfer (CPT); Wireless power transmitting (WPT);

Inductive power transfer (IPT); Coupler; Coil designs; Ferromagnetic

materials; Ferrite cores; Charging efficiency; Power transfer ratings

Introduction

The mainly significant performance parameters and

objectives of a satisfied CPT system are power transfer rating level,

maximum charging distance, system maximum efficiency, charging tolerance

to misalignments, system size and weight. The power level can refer to

how long one full battery recharge would take for a full driving range

of EV. The maximum charging distance determines the vehicle chassis

structure for achieving contactless charging. The system efficiency is

the overall comprehensive parameter of the entire system, which

illustrates how electrically efficiently the CPT phenomenon operates

from AC power supply end to DC battery end for the EV. Charging

tolerance could reveal how the horizontal and longitudinal misalignments

caused by EV drivers’ parking habits impact the actual coupling

charging and power delivered between primary coil and secondary coil,

which also indicates how the flexibility and advantages of CPT systems

are when compared with conventional plug-in charging methods. The

stationary CPT technologies could comprise loosely inductive coupling

and electromagnetic resonant coupling depending

upon different operating frequency range levels and capacitive

compensation adoptions, which are both based on inductive coupling

phenomenon and most of the time are collectively called inductive power

transfer (IPT) in the literature.

Principles of Stationary CPT systems

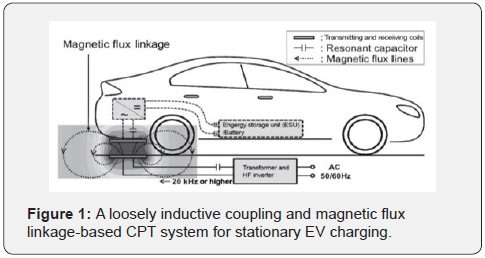

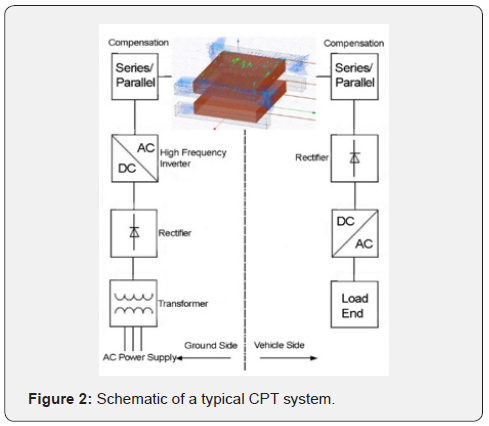

For the technical background and fundamental

principles of contactless power transfer systems, Figure 1 and Figure 2

illustrate the typical systematic diagram and basics of IPT based

stationary CPT systems. When the IPT charging system is activated by the

signal from EVs reaching over the particular charging platform, the

power supply under pavement will provide 230V AC mains to a transformer

converter which could convert and rectify the high voltage power to

required range of DC voltage. Then, a high frequency (HF) inverter

converts the low frequency DC power to HF AC power. Before being sent to

transmitting pad, the HF AC power is supposed to go through the

compensation module [1] which is considered to optimize the transformer

loss factor. Contactless power transfer coupler transmits the power to

the vehicle side via

effects of magnetic flux linkage namely inductive phenomenon.

After receiving the induced AC power, the compensation circuit

and rectifier/AC-DC converter would operate on the power then

the DC to DC converter of direct conversion method converts the

energy to a required voltage with appropriate low frequencies for

battery energy storage in the end of the whole CPT system. At a

basic level of a real-world CPT system, a power supply requirement

before the coupling module as depicted in Figure 2 is supposed to

include an input rectifier and filtering section, an H bridge inverter

section and current controller if necessary.

History

In 1887, Nikola Tesla invented induction machine that converts

electrical power to mechanical power from a stator to a rotor,

which inspired Tesla again to come up with the idea of wirelessly

transmitting energy via large air gaps based on the principle of

electromagnetic induction machine that was just technically and

commercially proved by himself. In 1901, the concept of wireless

power transmitting (WPT) was firstly proposed and was believed

by Nikola Tesla that it can be used to transfer electricity even far

from America to Europe with an electromagnetics based giant

tower named Wardenclyffe tower in USA, which was terminated

by US government in 1917 and proved that the actual coupling

distance is a huge obstacle to WPT efficiency and effectiveness.

Since then, some experiments were implemented in order to

wirelessly transfer power to a moving train with coupled energy

but still went unsuccessful, which on the other hand proved that

only low-power signal could be transmitted over large distances

such as radio frequency (RF) signals, microwaves, etc. A conclusion

was made at that time that electrical power wirelessly transmitted

is practically impossible from a power point of view throughout

the rest of 19th century [2]. Whilst on the ‘signals’ side, the

sciences over communication systems, non-contacted current

sensors and inductive antennas had been significantly developed

based on Maxwell equations, laws of Ampere’s and Faraday’s and

attempts of Nikola Tesla’s WPT.

With the attempts of powering EVs inductively since 1970s,

stationary CPT topics were re-proposed at the same time. In

1986, Kelly and Owens [3] designed a wireless power transfer

method for a low-power level aircraft entertainment system

with 38 kHz currents going through wires under the carpet

successfully coupling and delivering 8 W power for each passenger

entertainment platform despite very low transfer efficiency.

In 1990, this wireless aircraft entertainment system powering

innovation named ‘regulator for inductively coupled power

distribution system’ was enhanced with a voltage controller and

was patented by Turner and Roth for Boeing aircrafts in the US [4]. In the beginning of 1990s, as academic pioneers, Boys and

Green developed a systematic stationary CPT technology and

patented it in the US [5] with the first definitional names in

this area: inductive power transfer (IPT) or inductively coupled

power transmission (ICPT) system, which includes an elongate

inductor, parallel capacitive compensation, paralleled pickup coils,

decoupling and voltage controllers [6]. This complete IPT system

was modified and improved with enhanced control circuits by

Boys, Covic and Green in 2000, which resulted in an output of up

to 600W with a maximum voltage of 600V at 10 kHz by the system

power supply [7] and, thereby from the power point of view, it was

apparently unable to sufficiently power tens of kilowatts level EVs

or to accomplish hundreds of kilowatts level required fast highpower

battery charging cycles of EVs.

Since 2000, the performances of different stationary CPT

approaches were significantly improved most of the cases in lab

researches rather than industrial level applications. In 2007, MIT

WiTricity project group made a demonstration and claimed that

their wireless power transmission system can lighten a 60-W

bulb over 1 and 2 meters at 9.9 MHz with a transfer efficiency of

between 30% and 90%. This demonstration itself was convincing

but the measured results were unavoidably doubtful when

analysed according to previous studies and experiments over the

past decades in the literature. Nevertheless, the development of

stationary CPT technologies has been facilitated dramatically by

the academic interests and the commercial market requirement

of EVs towards pursuits of zero emission transportation era in the

21st century.

Current status

Among the various previous studies and reports in the

literature, it can be noticed that numerous subtopics have been covered and many breakthroughs have been made towards the

CPT system performance optimization and the commercially

productive realization for EVs. A variety of applications based

on inductive power transfer principle have diversified and the

actual technical challenges have been becoming more noticeable

at the same time, especially for the stationary and dynamic

high power required contactless charging for real-world EVs.

Nonetheless, the inductive coupling-based CPT technologies

and the derived techniques are promising. This section briefly

reviews the developments of stationary charging for EVs over

the past decade and presents the state of the art of stationary

CPT method.

More recently within the past decade, a series of

research institutes, university research groups and industrial

manufacturers have been playing pioneer roles in this field and

making new knowledge contributions from different aspects. Oak

Ridge National Laboratory (ORNL), as a bullet research institute

sponsored by the US Department of Energy in the CPT area, has

carried out some practical experiments empirically resulting in

some analyses and conclusive methods in the national research

centre lab in Tennessee. ORNL focuses on grid-tied high frequency

power inverter, grid side regulation converter, control system and

loosely coupled coil design. Based on the new ultra-thin silicon

IGBT technology, an experimental power inverter and a grid-tied

power converter were designed and tested by ORNL in 2012 [8],

which aims to minimize the mass and size of the coil, rectifier,

filtering, wires, and other components mounted on the secondary

side of vehicle chassis [9].

A 5-kW output inductive stationary CPT system was designed

by a group of the Utah State University, in which an external 37-W

power required FPGA sensors/controller was added to the CPT

system for the dual-side control. Circular coils and LCL converter

were used in this system. Practical experiments in this study were

used to validate the effectiveness of the proposed schematic, by

which the researchers claimed that the system can maintain a

very optimistic efficiency from the grid side to the load in spite

of too many ideally assumed conditions that were made in the

derivative analyses and post-data processing [10]. Nonetheless,

a dual-side control method in this report was proposed to the

inductive coupling system as an innovative way. A researcher of

the University of British Columbia deployed a set of magnetic gears

as transmitting and receiving magnets, an electric motor on the

ground side and a generator on a car chassis to realize a wireless

power transmitting, which is implemented and accomplished

via coupling magnetic gears and driving the generator on the

car to power the vehicle motor. It was claimed that this system

could reach a maximum transmission part efficiency of 81%

with a transferred power of 1.6 kW at a very low frequency of

150 Hz [11]. Regarding the feasibility and realization by gear

coupling and re-generating electricity in a real-world EV charging

application, the proposed system seems to be doubtful in this

study as the additional process of driving the secondary generator

via the magnetic field stored energy for inductively producing the

electricity itself would unavoidably introduce more power losses

eventually contributing to a further reduction of overall system

efficiency ratio.

Two researchers of the Setsunan university in Japan

conducted investigations on several different coil dimensions,

in which it was found that three-dimensional horn-shaped

antennas as transmitting and receiving coils could lead to higher

power transfer efficiency than patch and array antennas whilst

the patch antennas in a nature of planar could be more practical

and suitable for EVs chassis CPT system installation. Thus, the

size and operation performance are to be a trade-off when

considering the entire stationary CPT system from design to

actual fabrication onto EVs. In this study [12] of the University of

Setsunan, the system operating frequency is between 1.2 Ghz and

2.45 GHz, which is in a range of HF. Besides, it is claimed that the

array antennas perform with lower transmission loss than patch

antennas at 2.45 GHz and with a transmission efficiency of over

20% despite of unknown actual power transferred through the

entire system.

A team of Tokyo University contributed numbers of

reports to the field of CPT technologies in the past ten years. Based

on the method conceptualized and named with electromagnetic

resonant coupling by MIT WiTricity in 2007, the research group

of Tokyo University started studying the feasibility and technical

performance of this method with theoretical and practical depth

since 2009. Different from the previous inductive power transfer

(IPT) methods and concepts, the proposed electromagnetic

resonant coupling technology emphasizes on impedance matching

[13] in order for the whole system to approximate to magnetic

resonance, by which predictably the energy transfer efficiency of

the CPT system could be optimized and theoretically the actual

power rating to the load could be very satisfactory.

This group of researchers considered the CPT technology as

small-sized helical antenna transmission topics and pure electrical

equivalence problems [14,15] which led to a convenience of

investigating the system with the antenna scattering parameter

(S-parameter) analysis and the direct experimental methods

of using a vector network analyser (VNA) [16] to measure the

outputs at a usable frequency of the industrial, scientific and

medical (ISM) band-13.56 MHz [17]. Significantly, the impedance

matching theory contributes to the theoretical structure

construction of CPT technologies, especially for the magnetic

resonance accomplishment in this case. Whilst, the over-idealized

impedance matching circuits used in this case neglects the

non-linear magnetic circuit part in the coupling module, which

determines a lot regarding how the actual electromagnetic flux

distribution contributes to the real-time coupling phenomenon

over the air or core based distance with non-linear magnetic

characteristics in nature such as B-H curves and hysteresis effects

in the electromagnetic field. Thus, the absolutely equivalent

circuit method in the case of this research group may be not

sufficiently appropriate and suitable for a CPT system scenario. Besides, working at megahertz level operating frequency and

considering the system as a pure antenna problem especially with

traditional scattering parameter analysis may be not proper as

firstly the real-world CPT systems are not milliwatts level ‘signal

transmission’ topics from power point of view, and secondly the

VNA measurement with a two-port network S-parameter method

may not be adequately applicable any more when it comes to

kilowatts level electrical power issues despite of resonance status.

Nevertheless, the University of Tokyo team did make

contributions towards the knowledge gaps at that time in the

last years of 2000s. With the same methodology, a battery hybrid

energy storage system was also studied by this research group,

by which it is claimed that both the transmission side power

control configuration and the receiving antenna side controller

were designed to achieve satisfactory power charging without

communication units between transmitting and receiving

antennas [18]. However, the Tokyo University research team

turned to study the CPT systems in a loosely coupled frequency

range in the order of kilohertz [19] rather than megahertz

anymore since about 2014. More practically in laboratory and

realistically in applications this time, the researchers mainly

investigated the circuit topologies, transmission coil types, control

methods and capacitor compensations in depth, pointing out that

the effectiveness of magnetic resonance to the wireless power

transfer coupling purpose and proving that the new methodology

contributes more to the system efficiency and power transfer rating

issues [20] with results of 40-90% and 60W, respectively. On the

other side in industry, several technology driven companies and

manufacturers have also been making contributions to the field

of emerging wireless power transfer technologies for stationary

charging from multiple levels and aspects over the past twenty

years, such as WiTricity Corporation, Bombardier, HEVO Power,

Qualcomm Group, Conductix-Wampfler etc.

As mentioned before in the last section, WiTricity as a

corporation was founded by a group of MIT researchers to

investigate and invent wireless energy transmission terminals

for commercial purposes since the first demonstration in 2006.

With the proposed resonance coupling method, WiTricity team

designed a CPT system with tuned coils to wirelessly transfer

power which was claimed with 60 W to 3.3 kW over one meter

at 145-kHz operating frequency [21-24]. Afterwards in 2011,

some other researchers in East Asia carried out resonant coupling

simulations based on WiTricity designs and studies the position

tolerance of the method, by which it was claimed that the simulated

WiTricity model showed a maximum performance at 2.34 MHz

with a coil distance of 50 mm [25]. However, in this report a

real power rating and effectively convincing system efficiency

were not derived and discussed in detail although the peak

values of output voltage magnitudes corresponding to various

coil distances and frequencies were recorded and compared.

Bombardier Transportation company, a leading technology and

solution supplier in Germany, tested their wireless static charging

system called PRIMOVE for buses in 2013. As part of the pure

electric public buses, the PRIMOVE system has been integrated

with improved EV system via this project. Bombardier designed

their own control unit named ‘vehicle detection and segment

control’ (VDSC) and interface called ‘supervisory control and data

acquisition’ (SCADA) subsystems at industrial levels [26], which

seems to be feasible and successful in the real-world application

despite of insufficient technical reports or data released and

published yet. HEVO Power is another technology provider in the US

which aims to innovate a wireless charging system for public

transportations. This company proposed a stationary system

requiring a fixed operating frequency of 85 kHz and targeting at

transferring up to 10-kW power over an air gap of about 30 cm.

It was claimed in 2014 that the receiving side prototype mounted

on the vehicle weighs 11 to 23 kg and that the heating problems

on both the vehicle and ground charging sides can be prevented

by their parking zone design and mobile phone app monitoring

[27]. Qualcomm, a pioneer company dedicated in communication

technologies, informatics and lately emerging wireless power

transmission, has also been implementing research programs

towards an optimal wireless charging equipment for both lowpower

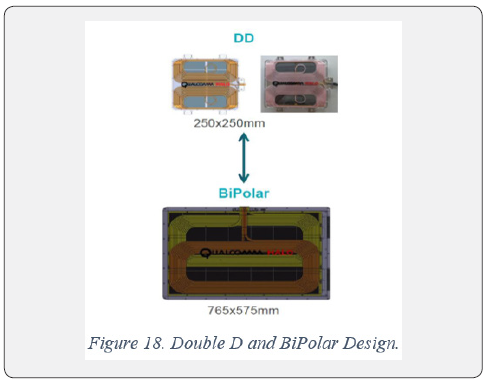

electronic devices and high-power charging applications.Qualcomm Halo is a specific project regarding achieving CPT charging for EVs. Qualcomm aims to realize three options of charging power ratings for future customers in their report in 2013, which are 3.3 kW, 6.6 kW and 20 kW and targets at very high and stable efficiency rate of over 90%. With IPT method, proposed BiPolar and DD coil designs, Qualcomm claimed that their Halo IPT system used 20-kHz operating frequency in the simulation experiments and trial runs of this prototype would be implemented in East London in 2011. It can be noticed that, from the official reports and research report [28] in collaboration with Auckland University, Qualcomm Halo project is very practically profound and technically convincing with strong simulation supports and mathematically theoretical representations by themselves and other researchers [29].

Besides, the double D method has been patented by Qualcomm

years ago from commercial point of view. Conductix-Wampfler,

another technology company in CPT research, is very dedicated

in investigating inductive power transfer (IPT) techniques

and already patented their own IPT trademark in the US. This

company focuses on developing IPT system for automated guided

vehicles (AGV) in warehouse applications with robotics [30,31].

According to their reports until 2018, Conductix-Wampfler aims

to produce the power supply module, charging mat and power

pickup with charging manager unit. Technically, the power supply

AC voltage can be one-phase 100-240V or three-phase 380-480 V

at 50 or 60 Hz, the output power and current can be 1.5 kW and 5

A, respectively. Their power pickup namely receiving coil module with charging manager subsystem aims to inductively receive

about 55 V induced voltage and 10 A current to send to charge a

24-V DC battery with 12-A and 144-W after the power regulation,

DC/DC converter and current monitoring of the charging manager

subsystem. The dimensions of power pickup pad and charging

mat are H 80.3 mm x W 222 mm x D 216 mm and H 7 mm x W 435

mm x D 180 mm, respectively. The aim of the charging distance is

10 mm. It can be seen that Conductix-Wampfler shows not only

respectful ambitions but also technical skills in the industrial

applications for AGV in warehouse systems.

Proposed designs of coupling coils

As the most important part of contactless power transfer

systems with regards to the overall system outputs and

performances, the coupling module design especially the coil

geometry design plays a significant role in order for any types

of CPT architectures from both the power electronics and

electromagnetics perspectives to eventually address the three

main objectives: electrical power transfer ratings of the system;

efficiencies including overall system efficiency to the load end and

coupling part efficiency; CPT air gaps namely charging distances.

Therefore, it is very worthwhile proposing, analysing and

evaluating various coil designs to comprehensively implement the

investigations upon CPT technologies. In this section, the proposed

coil designs in the literature until present are to be enumerated

and briefly analysed.

Circular coils

Until present, from the academic studies to the real-world

commercial applications, the circular coil designs have become

the most common and acceptable approaches for various powerlever

devices such as wireless charging pads for smart phones and

many other portable electronic products. Also, as for the initial

feasibility for high-power level EVs contactless charging, circular

coil with its derivative topologies has been focused and developed

towards the optimizations and some of them are originally

derived from traditional pot cores, according to the reports in the

literature [32-34]. Within the current studies and even commercial

level applications, most of the circular coil designs are coreless

especially for low-power cases [35-37]. As known in transformer

theories and applications, the ferromagnetic cores like ferrite cores

are deployed to prevent excessive energy loss into surrounding

air and materials due to existence of magnetic leakage. And with

the fairly tiny air gap design crossing the core structure instead

of completely enclosed core loop, the core windings can have

minimum disadvantages when effects of proximity occur due to

hysteresis loss and eddy current loss. Similarly and theoretically,

deploying ferromagnetic cores like ferrite in CPT coil designs is

able to constrain magnetic flux lines to expected paths and to

shape the actual electromagnetic field in order to enhance the

effectiveness of coupling, which consequently improves the

wireless energy transfer system performance.

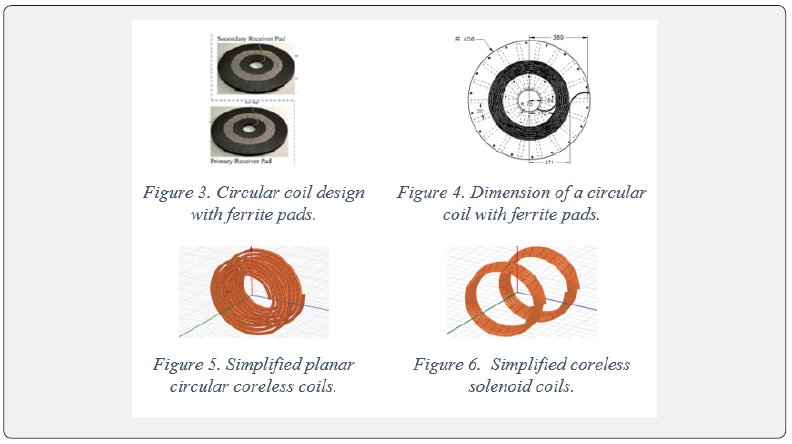

In most small-scale low-power CPT systems for portable

electronic devices like cell phones, wireless charging pads with

coreless coils can acquire more popularity due to pursuits of

relatively thin and lighter design from real-world customers,

certainly under acceptable conditions such as charging power

rating and basic efficiency to be at least satisfied by manufacturers’

efforts on advanced electronic circuitry and control unit designs.

However, high-power CPT applications are more supposed

to need cores to assure the satisfactions of the overall system

performance [38,39], for instance, the circular coil couplers with

solid ferrite pads could form the flux distribution much better. A

design of circular coil with ferrite pad is shown in Figures 3 &4

[10], in which the dimension is in mm. And two coreless circular

coil designs are illustrated in Figures 5&6 for comparisons.

In

addition, the derivatives of circular design have also been depicted

here in Figures 5&6 [40]. In this article, the former design could

be called a design of simplified planar circular coreless coils

and the latter one could be called a design of simplified coreless

solenoid coils, with a categorization nomenclature based on the

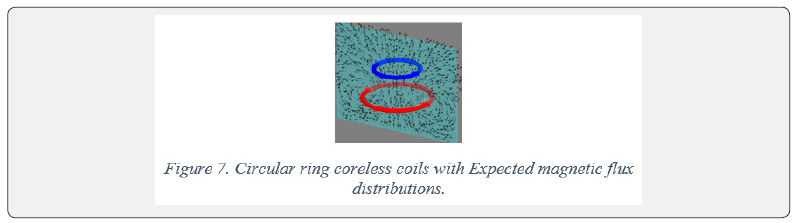

characteristics and natures introduced above. The model in Figure

7 could be named a design of circular ring coreless coils, which

illustrates expected magnetic flux lines and distributions in 3D

magnetic simulation. It can be seen that with no ferrite pads or

cores, the flux lines flow through the coils showing more naturally

and smoothly curved paths in air, which can be different from the

circular coils with shaping effects by ferromagnetic materials such

as ferrite pads used on the external sides.

Planar square coils

Geometrically, square windings can take better advantage of

the space under the chassis of vehicles for system installation.

Some reports also have already presented the designs regarding

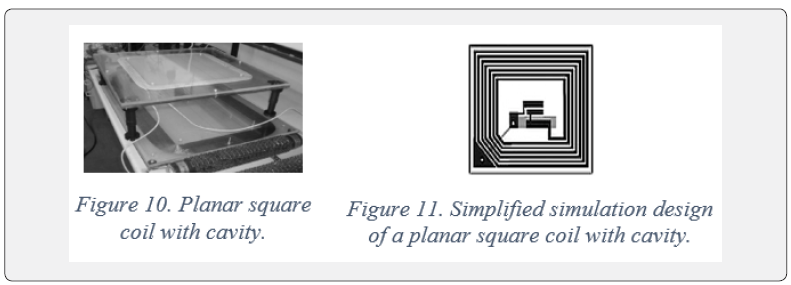

square coils and the derivatives and practically tested. The Oak

Ridge National Laboratory (ORNL) in the US proposed the detailed

designs of their square coupler shown in Figures 8&9 [8,9,41] for

which a category name of ‘planar square coil without a cavity’

can be applied based on the reviewed designs and categorization

nomenclature in this article. The square coils of ORNL are singlelayered

with multiple circles of windings as illustrated and the

winding wires are made of copper. No ferromagnetic materials

are used in this design. Considering different magnetic flux lines

generated and formed by whether or not a cavity exists in the

planar coils, another derivative design can be categorized into

‘planar square coils’ here. Compared with the planar square coil

without a cavity prototype, the model that can be named the

‘planar square coil with a cavity’ has been presented in [42], which

is nearly based on the same dimensional parameters except the

empty cavity design existence within the coils as shown in Figures

10&11.

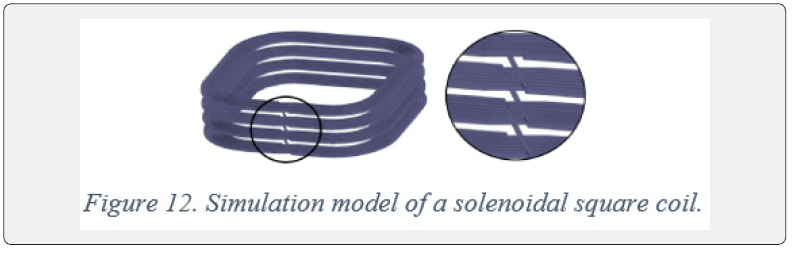

Solenoidal square coils

When the installation space under a vehicle chassis is not a

major issue, for instance for small-sized automated guided electric

vehicles (AGEV) in warehouse rather than on public traffic road,

a combination design of solenoid coils and square coils can be

proposed, which here is named ‘solenoidal square coil’ despite a

different name in the original report [43]. By a comparison analysis

in this article, it can be explained that, the huge dimensional size

of this kind of design can take advantage of the intracavity space

of the AGEV and theoretically present the optimal performance

of both planar square coil and solenoidal coil due to a larger

internal magnetic flux area and path length as shown in Figure

12. Expectedly, this solenoidal square coil design can improve the

magnetic flux density and eventually enhance the power transfer

efficiency and power rating, which however still needs to be tested

and proved with actual system output performance and feasibility

yet.

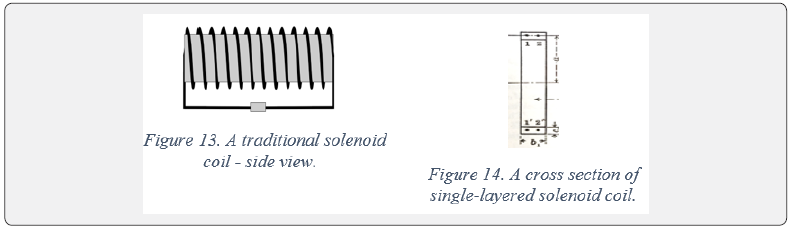

Helical solenoid coils

Similar to conventional solenoid structure, the helical solenoid

coil categorized here can be one of the applicable CPT coupler

designs. As shown in Figures 13&14 [44], the helical solenoid

coil design ideally has two coaxial solenoids with horizontal flux

central lines in parallel. With one solenoid as transmitting coil

on the primary side and another solenoid as receiving coil on

the secondary mounted on the vehicle chassis. Figure 14 shows

a cross section of a helical solenoid coil with single-layered

windings. This coil structure theoretically has satisfactory mutual

inductance when two coils have zero misalignment in parallel and

short coupling distance, especially for small electronic devices.

However, this design may have low tolerance to misalignments

which could be a challenge from the EV customer end in realworld

high-power applications if installed on vehicle chassis.

Ferrite cores can be inserted into the cylindrical centre in helical

solenoid coil design for coupling enhancement.

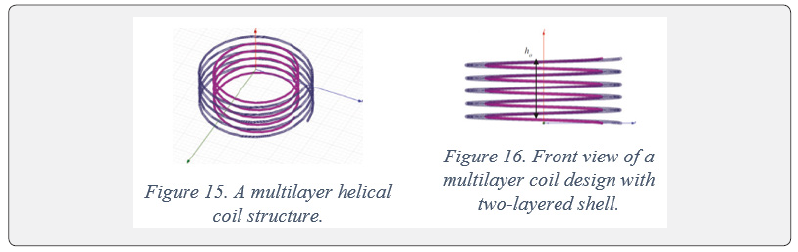

Multilayer helical coils

A novel design called ‘multi-layered helical coil’ is illustrated

in Figures15&16. Theoretically, with numbers of winding turns

and layers, the coil coupling, and mutual inductance will be

increased, consequently enhancing the CPT system performance.

When it comes to high frequency applications like CPT charging

for EVs, the total effects of proximity losses will be significant if

the distance of each turn and layer separation are too close, which

lowers the system efficiency [45]. Thus, this design is not suitable

for high frequency, space tightened and high power required

applications. Further investigations and experimental results

from practical prototypes rather than ideal simulation models are

still required to study this multi-layered helical coil design for the

feasibility and realization of CPT charging of EVs in the future.

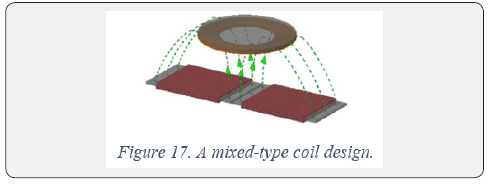

Mixed-type coils design

An innovative structure design shown in Figure 17 was

proposed by a team in Japan in 2015. This mixed-typed coil design

[19] is supposed to allow higher tolerance to misalignments,

smaller size and more compact installation for energy receiving

side on EVs as two coaxial square solenoid coils on the transmitting

side are expected to generate stronger magnetic field in order for

the circular receiving coil to capture more amount of magnetic flux

lines. Expectedly, the overall coil magnetic flux distribution of the

CPT system could be boosted when compared with a pure circular

coil design for the same size of chassis of EVs. However, this design

still needs to be further theoretically studied, practically tested

and comprehensively analysed from modelling to experiment due

to few reports in the literature until present.

Double D coils

A structure of double D shaped coils was proposed by

Qualcomm Halo program as illustrated in Figure 18. Two coils of

the ideal D shape winded with one long copper wire are on the

ground side as a transmitter, and a polarized receiving coil with

two partially overlapping windings is on the EV chassis side [46].

This DD design was reported to produce higher coupling than

a same-sized circular coil structure [47,48]. However, further

developments about DD coil design and its derivatives are required

by more numerical results and effective system performance.

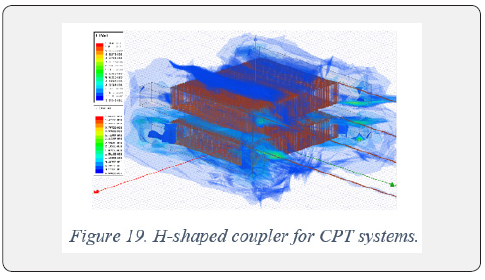

H-shaped coupler coils

A novel H-shaped coupler with ferromagnetic materials as

cores was proposed in [39,49]. In order to enhance the magnetic

field flux density and CPT coupling performance, different core

materials were tested and analysed. Besides, it was found that the

objectives of CPT systems can be addressed by adding shielding

shells. Especially with aluminium semi-enclosed shielding

shell, the CPT prototype can produce better electromagnetic

characteristics and output more satisfactory system performance

[50], which reflects the effectiveness and feasibility of using

ferromagnetic materials and shielding methods Figure 19.

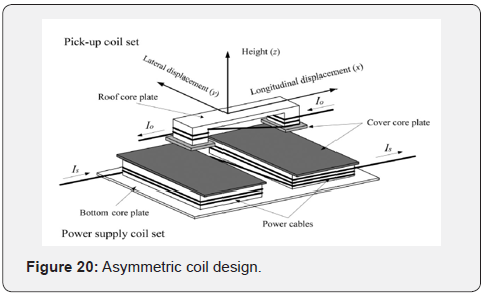

Asymmetric coils

The asymmetric coil structured in Figure 20 was proposed

in 2014 in order to investigate the impact of tolerance to the

stationary CPT system performance. The receiving coil is smaller

than the energy transiting coil set with a purpose of improving

the tolerance of misalignments when parking a vehicle [51].

This structurally innovative coupler design with a transmitting

bottom set size of 200 cm x 100 cm each and a pickup set size

of 16 cm x 16 cm each is claimed to output 15 kW at 20 kHz and

the maximum misalignments can be 40 cm and 20 cm for lateral

and longitudinal axes. This coil design contains ferrite cores as a

ferromagnetic material to facilitate the field. The power supply

is a current source of maximum 100 A in the simulation models.

Nevertheless, further studies about the feasibility for real-world

EVs contactless charging with this type of design are required in

the future, addressing the other major objectives of CPT systems.

Conclusion

In this article, the brief history and basics of CPT systems

using inductive power transfer have been introduced. A series

of both leading research institutes and pioneer industrial

companies worldwide have been listed and discussed in terms

of the development directions, proposed methods and concepts

over CPT technologies. In addition, most of the currently proposed

coupler coil designs have been described and reviewed towards

the major objectives of CPT technologies.

No comments:

Post a Comment