Nutrition & Food Science International Journal Juniper Publishers

Authored by Talwinder S Kahlon*

Abstract

The sensory evaluation of whole grain, gluten-free, Buckwheat (B), Peanut Meal (P) and Beets (B) flatbreads was conducted. The flatbreads were BPB, BPB-Onions, BPB-Garlic and BPB-Ginger. Buckwheat is an ancient grain, gluten-free and good source of many essential minerals. Peanut Meal was utilized to formulate higher protein flatbreads and to add value to this low value farm byproduct. Fresh beets a vegetable with bile acid binding and health promoting potential was used to increase vegetable consumption. Onions, garlic and ginger contain many healthful phytonutrients. The levels of buckwheat, peanut meal, beets, onions, garlic and ginger were determined by consensus of the laboratory personnel. Flatbread dough was prepared using 55-83ml water per 100g as is ingredients. The ingredients were Buckwheat flour, Peanut Meal and Beets (22-33%) as is basis. Onions, Garlic and Ginger flatbreads contained 33%, 8% and 20% of the respective ingredients. 50g flatbread dough was pressed between parchment paper in Sol Luna tortilla press to about 8-inch circle. They were cooked in flatbread cooker for 2-2.25 minutes at (165-195 ͦC). Seventy-seven in-house volunteers evaluated Color/Appearance, Texture/Mouth feel as well as Acceptance of the four kinds of flatbreads tested to be statistically similar. Odor/Aroma of BPB-Onions was significantly (p ≤ 0.05) higher than BPB flatbreads. Taste/Flavor of the BPB-Onions and BPB-Garlic was similar and significantly better than BPB-Ginger and BPB flatbreads. For BPB-Ginger flatbreads these values were also significantly higher than BPB. The acceptance of the flatbreads tested was BPB-Onions 79%, BPB-Garlic 78%, BPB 68% and BPB-Ginger 66%. These flat breads used only 3-4 ingredients and could be made in any house kitchen or commercial production. These whole gain, high protein, gluten-free, vegetable, flatbreads offer tasty, nutritious and healthy choice to all and those sensitive to gluten.

Keywords: Buckwheat; Peanut meal; Beets; Whole grain; Gluten-free; Flatbreads

Abbrevations: BPB: Buckwheat Peanut Meal Beets; RDI: Reference Daily Intake; ρb: Bulk Density; ρt: True Density; Aw: Water Activity; DM: Dry Matter

Introduction

Flatbreads are the oldest of all bread products and are consumed in North Africa, Southern Europe, the Middle-East, Indian subcontinent, Turkey and Central America. Throughout history, many if not most cultures have had foods that can be classified as flatbreads.

Flatbreads are called by various names like “Bing”, “Chapati”, “Metzo”, “Nan”, “Pita”, “Roti”, and “Tortilla”. There are one hundred eleven different names for flatbreads in the world [1]. Flatbreads are becoming popular in the Western world for sandwiches, wraps and pizzas. Flatbreads are generally round and may be leavened or unleavened (without yeast or chemical leavening agents) and contain single or many layers. Qarooni et al. [2] reviewed the flatbreads from around the world. Wheat is a common ingredient in most flatbreads. In Asia and Africa, wheat-based flatbreads are commonly baked on a griddle (roti or chapati) or in an oven (naan) or pan fried (paratha) or deep-fat fried (puri or bhatoora). Flatbreads can be used as dish or spoon to scoop up vegetables or meat portions of the meal. They can be served with soups, curries, vegetables, and meat dishes. A variety of other ingredients, such as meats, vegetables, condiments and spices, may be incorporated into flatbread doughs. Consumption of flatbreads with breakfast, lunch, and dinner meals is common in cultures in which flatbreads are the staple. As world changing demographics and the expanded distribution of ethnic foods among new populations, flatbreads are increasing in popularity. Recognizing this trend, in USA some fast food chains have successfully introduced flatbread wraps and sandwiches. American Baking Society will be conducting scholarships awarding contest “The 2019 Product Development Theme is Flatbreads” [3]. The U.S. Department of Agriculture (USDA) Dietary Guidelines for Americans 2015-2020 [4], consuming grains at least one-half as whole grains like wheat (gluten containing) or buckwheat (gluten free), colorful vegetables like beets, and variety of nuts like peanuts as protein and fat sources. Consumption of whole grain products would lower the risk of many preventable life style degenerative diseases, Whole Grain Council [5]. Halnaes et al. [6] reported that heart disease risk was lowered with whole grain rye and oats but not wheat. Wheat is the primary grain used in loafs and flatbreads due to the special properties of gluten. Hypersensitivity to gluten has been increasing worldwide. Individuals with celiac disease, who are hypersensitive to gluten, must follow a gluten-free diet, which restricts their wheat containing options. Hypersensitivity to gluten results in eroding of the lining of small intestines Lebwohl et al. [7]. This results in delayed growth and many serious health problems. Healthy intestinal lining is required to absorb the needed nutrients. Food and Drug Administration (FDA) [8] defines “gluten-free” with less than 20 parts per million of gluten This is the level that can be validly tested and can be tolerated by most gluten sensitive individuals. Transaminase a microbial enzyme is used to glue animal meat scraps to make low cost meat patties that are commonly served is fast food establishments. Transamination in the gut potentially makes gluten hypersensitive. Another reason could be that pollution and toxic environment has altered gut microbiome resulting in loss of gluten immunity. The short, high yielding wheat varieties were produced by silencing the Gibberellin gene. Gluten in the new wheat varieties could be the source of hypersensitivity. Old world wheat varieties evolved over centuries were hypoallergenic. If one family member is gluten sensitive, the whole family needs to consume gluten-free foods. As gluten contamination in the kitchen would enlist allergic reaction in celiac patients, Hollon et al. [9]. Most individuals and especially children and seniors do not meet the recommended intake of whole grains, protein and vegetables Mother-Jones [10]. The development of whole grain, gluten-free, high protein, vegetable, nutritious and tasty flatbreads would help to meet such a need. Consumers need to be educated to desire nutritious home cooked or commercially produced health promoting flatbreads. Such flatbreads could include onions, garlic and ginger with healthful phytonutrients.

Buckwheat

Buckwheat (Fagopyrum esculentum) is a pseudocereal, a low input crop with relatively high yields that can be grown in marginal lands. Buckwheat has been providing essential nutrients, vitamins, energy, and fiber to humanity for approximately 8,000 years. Its grain has unique triangular shape with size of wheat kernel. Buckwheat contains higher levels of zinc, copper, and manganese than other cereal grains, and the bioavailability of zinc, copper, and potassium from buckwheat is quite high. One cup (155g) of buckwheat provides Reference Daily Intake (RDI) of manganese 34%, copper 28%, magnesium 21%, dietary fiber 18% and phosphorus 17%. As it contains no gluten that makes it suitable for people who are sensitive to wheat or other grains that contain gluten. Top buckwheat production in thousand tons is Russia, 700; China, 662; Ukraine, 167; France, 111; US and Poland, 83 each and Brazil 64, UN FAO [11].

Peanuts

Peanuts cultivation in South America dates back 7500 years. In the first century its production started in Mexico and spread to North America, China, India and Africa. Top peanuts producing countries in million metric tons are China, 17.8; India, 6.7; United States, 3.3; Nigeria, 3.2; Indonesia and Myanmar, 1.1 each; Senegal, 1.4; and Chad 1 [12]. Peanuts produced in the U.S. are mostly used in food and confection products. More than 50 percent of the world production of peanuts is crushed for its oil. World production of peanuts in 2017-18 was over 45 million metric tons per year. Nearly 23 million tons of peanuts are used to extract oil resulting in 12 million tons of peanut meal. Peanut meal contains 44% protein. However, it is a low value farm byproduct mainly used as animal feed. Peanut Meal when produced as food grade without the use of organic solvents could be used to make high protein nutritious food products. That would result in significant value addition to peanut growers.

Beets

Beets have been grown for food since ancient times. Both the leaves and the root are edible. Beets most distinguishing characteristic is their bright red pigment, sometimes used as a dye in vegetable patties or burgers. Beets are also rich source of alkaloid betaine, as well as B-vitamin folate. Betaine and folate together lower blood homocysteine. High levels of homocysteine increase risk of heart disease. Beets are moderate source of iron, vitamin C and fiber. Beets are rich in nitrates, which the body converts to nitric oxide a compound that relaxes and dilates blood vessels, resulting in better circulation, and possibly lower blood pressure and heart disease risk. Beets bind significantly more bile acids than many other vegetables, Kahlon et al. [13,14]. Binding bile acids reduces fat absorption with potential to lower cholesterol.

Garlic

Garlic (Allium sativum) is a widely used spice. In 2014 world production of garlic was 25 million tons. Top garlic producers in million tons are: China, 21.3; India, 1.4; Bangladesh 0.4; South Korea, Egypt and Russia 0.3 each [15]. Sharp flavor and taste of garlic is due to allicin, a sulfur containing compound. One ounce (28g) of garlic RDI of manganese (23%), vitamin B6 (17%), vitamin C (15%), selenium (6%). Garlic contains several phytonutrients with potential health benefits [16,17].

Onions

Onions (Allium cepa), is a vegetable and is most widely cultivated spice. World production of onion in 2014 was 88.5 million tons. Top producers in million tons are: China 24.8; India, 19.4; Egypt 3.1; USA, 3.0; Iran and Turkey, 2.3 each [18]. Phytonutrients and polyphenols of onions have health promoting potential [19].

Ginger

Ginger (Zingiber officinale), is a common spice used in various cuisines. World production of ginger in 2016 was 3.3 million metric tons. Top ginger producers were India, 1.1; Nigeria and China, 0.5 each; Indonesia and Nepal, 0.3 each; Thailand, 0.2 [20]. Ginger can be used fresh, dried, powdered, or as an oil or juice, and is sometimes added to processed foods and cosmetics. The unique fragrance and flavor of ginger come from its natural oils, the most important of which is gingerol. Gingerol is the main bioactive compound in ginger, responsible for much of its medicinal properties. It has powerful anti-inflammatory and antioxidant effects [21]. Thomson et al. [22] reported that ginger could be used as a cholesterol-lowering, antithrombotic and anti inflammatory agent. Addition of 4% ginger prevented the effect of hypertension inducing drug in rats [23].

The objective this study was to evaluate four kinds of ancient whole grain, gluten-free, Buckwheat, high protein, vegetable, nutritious and tasty flatbreads. The aim was that these flatbreads should have ≥70% acceptability and nearly 25% protein. The flatbreads were Buckwheat Peanut Meal Beets (BPB), BPBOnions, BPB-Garlic and BPB-Ginger.

Materials and Methods

Ancient whole grain buckwheat (hulls removed), peanuts, beets, red onions, garlic bulbs and ginger root were purchased from local foods markets. Buckwheat flour was prepared by using Blendtec Kitchen Mill Model 91 at medium setting (Blendtec Inc., Wichita, Kansas, USA). Peanut meal was produced by extracting oil using Vevor Oil Press (Joyfay.com, Cleveland, Ohio, USA). Beets and Garlic peeled, Onions and ginger chopped using Mini- Prep Processor (Cuisinart.com, East Windsor, New Jersey, USA). Prepared flatbreads and the ingredients (Buckwheat flour, Peanut Meal, Beets, Red Onions, Garlic and Ginger) were analyzed for nitrogen, using, AOAC method 990.03 [24] by Leco FP628 analyzer (Leco Corporation, St Joseph, MI); crude fat by Soxhlet extraction with petroleum ether using, AOAC method 27.006 [25]; ash using, AOAC method 923.03 and moisture, using, AOAC method 925.10 [26].

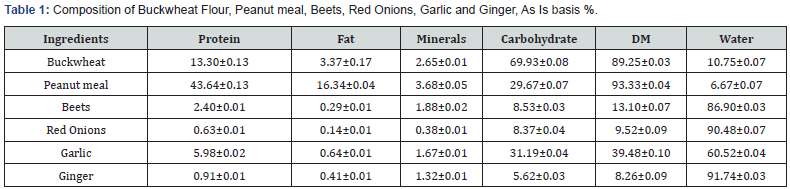

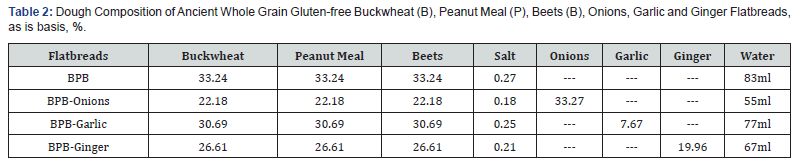

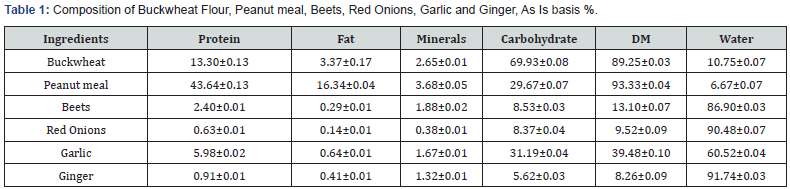

Composition of Buckwheat flour, Peanut Meal, Beets, Onions, Garlic and Ginger is given in Table 1. Various levels of buckwheat, peanut meal, beets, onions, garlic and ginger were evaluated. The final composition of acceptable, tasty flatbreads was decided by the consensus of laboratory personnel. Dough Composition of the flatbreads tested on as is basis was Buckwheat, Peanut Meal and Beets (23-33%), Onions (33%), Garlic (8%) and Ginger (20%) is given in Table 2. Flatbreads dough was prepared by adding 55- 83ml water to 100g of as is ingredients. Dough was set at room temperature for 30 min.

Values are mean ± SEM; Nitrogen to protein factors used was 6.25; Dry matter, DM. Carbohydrate = [100 − (Protein + Fat + Ash)]. Samples were analyzed in triplicates.

Level of Onions, Garlic and Ginger was decided by consensus of laboratory personnel. Dough was set at room temperature for 30 min.

Nitrogen to protein factors used was 6.25. Dry matter, DM. Carbohydrate = [Dry Matter − (Protein + Fat + Ash)]. Samples were analyzed in triplicates. Values are mean±SEM, (n=3).

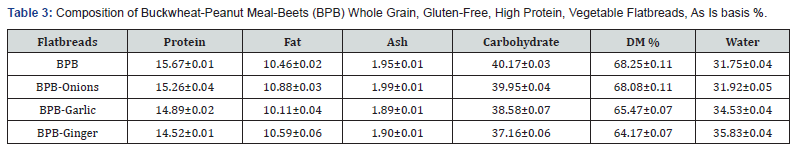

Composition of cooked ancient whole grain, gluten-free, high protein, vegetable flatbreads is given in (Table 3). These flatbreads on as is basis contained protein 15-16%, crude fat (10-11%), ash (1.9-2.0%), carbohydrate (37-40%), dry matter (64-68%) and water (31-36%). On dry matter basis (DM) these values were protein (22-23%), crude fat (15-17%), ash (3%) and carbohydrate (58-59%). The objective to attaining final product with 25% protein on DM basis ended up short by only 2-3%. The mineral content of the flatbreads tested was very desirable (3%) with only less than (0.2-0.3%) added salt (Table 2).

Preparation of flatbreads

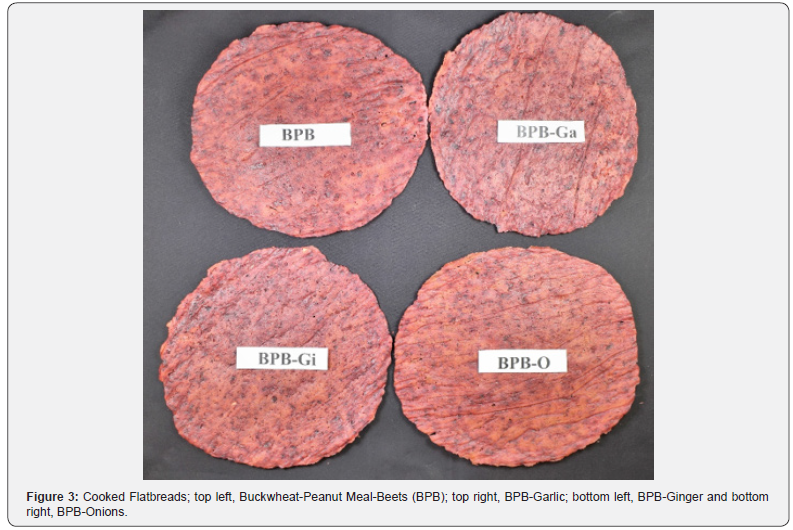

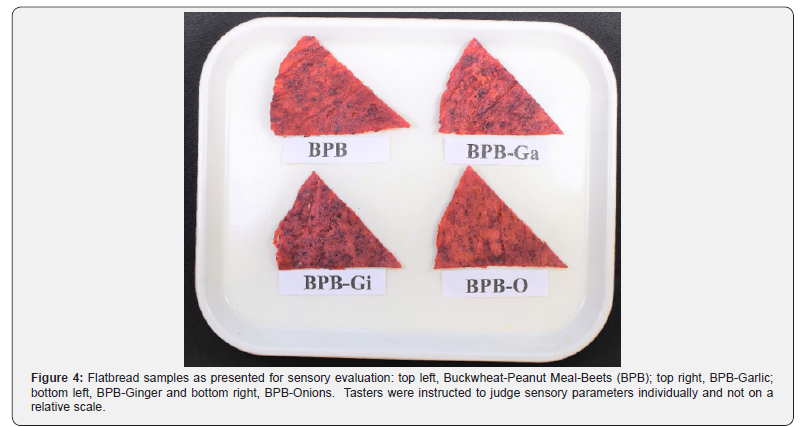

Small portions (50g) of dough was put between parchment paper (Renoldskitchens.com, non-stick, up to 215 ͦC safe) and pressed to about 17cm circle in a 20cm Sol Luna Tortilla Flatbread Press (Figure 1). Dough could be prepared by hand mixing and flatbreads could be made into circles by pressing the dough with moist hands or using a rolling pin. Flatbreads may be prepared and stored in the freezer. These flatbreads could be cooked as needed for sensory evaluation or consumption. Flatbreads were cooked for 2-2.25 minutes (half time each side) the day of sensory evaluation between parchment paper on a 1000Watts Cucina Pro Flatbread Maker Figure 2. The cooking temperature ranged from 165-195 °C as measured by Fluke 61 Infrared Thermometer. For crispier or chewy flatbreads, cooking time can be adjusted up or down as desired according to the personal preference. Cooked ancient grain gluten-free flatbreads are shown in Figure 3, top left BPB, top right BPB-Garlic, bottom left BPB-Ginger and bottom right BPB-Onions. Cooked flatbreads were stored in an insulated lunch boxes. Flatbreads were cut into 8 sectors with a pizza cutter and all four kinds of flat bread samples were presented to the volunteer tastes, appropriately labelled as shown in Figure 4 (A) BPB; (B) BPB-Garlic; (C) BPB-Ginger and (D) BPB-Onions. The instructions were to evaluate sensory parameters for each flatbread sample individually and not on a relative scale. The tasters, n = 77; evaluated the gluten-free flatbreads for Color/ Appearance, Odor/Aroma, Taste/Flavor, Texture/Mouth-feel on a scale of 1 - 5 (like very much = 5, like slightly = 4, neutral = 3, dislike slightly = 2, dislike very much = 1). The overall acceptable preference was on a scale of 1 - 2 (acceptable = 2, not acceptable = 1).

Water Activity

Water activity of the Buckwheat Peanut Meal Beets (BPB) flatbreads was measured at 25.01 ± 0.02 °C in triplicate using an Aqua Lab 4TE dew point water activity meter (Decagon Devices, Inc., Pullman, WA).

Density

True density: True density (ρt) of the BPB flatbreads was determined using gas displacement pycnometer AccuPyc II 1340 (Micromeritics Instrument Co., Norcross, GA 30093) at 21.4 ± 0.4 °C. Sample of flatbreads were dried in triplicate at room temperature for 15h at 0% relative humidity in a vacuum desiccator with anhydrous calcium sulfate (W. A. Hammond Drierite, Xenia, OH). After drying, small pieces of sample were compressed into a density measuring cylinder of the pycnometer and five true density measurements were recorded.

Bulk density: The bulk density (ρb) of BKB flatbreads was measured using Syntron Vibra-Flow, Model F-T01 (Syntron Company Homer City PA). In a 202ml volume jar, displacement by 10g flatbread sample in Ottawa Sand was measured. The first reading was taken after shaking for 15 min., subsequent two readings were taken after additional shaking for 5 min each time.

Texture Analysis

Texture of the flatbreads was determined with a TA.XT2 Plus (Texture Technologies Corp., Hamilton, MA) using a TA-108N Large Film Extensibility Rig. The Large Film Extensibility Rig is an acrylic cylinder with a 63mm diameter opening mounted on an aluminum platform. Each flatbread was pre-punched with four holes to fit over the uniform alignment pins. The test samples were held tightly with alignment pins between plated with similar openings. The platform held the flatbreads with uniform tension. The probe was a TA-108N 7/16” diameter acrylic cylinder which has a radius edge to minimize any cutting of the moist flatbreads. The probe traveled at 1.7mm/second until the flatbread surface was detected at 20grams force. The probe then traveled down at the same speed for up to 10mm, a distance chosen to stretch all the flatbreads until they thoroughly ruptured. The probe withdrew at the same speed as well. The test was designed to measure flatbreads strechability, breaking point and firmness. All products were tested at room temperature. Each test was conducted 10 times.

Statistical analysis

Statistical analysis of BPB flatbreads sensory evaluation data scale (1-5) and acceptability data scale (1-2) for all 77 individual tasters were analyzed with Minitab software (version 14.12.0, Minitab Inc., State College, PA) using basic statistics for mean ± SEM and one-way analysis of variance and Tuckey’s multiple comparison tests with (p ≤ 0.05) was considered the criterion of significance.

Results and Discussion

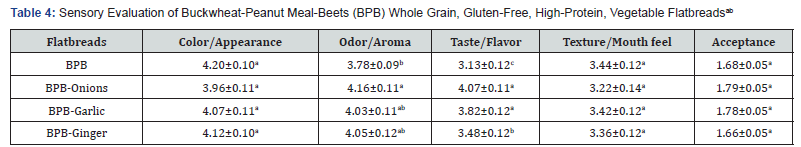

Seventy-seven in-house volunteers judged Color/Appearance, Texture/Mouth feel as well as Acceptance of the four kinds of flatbreads tested to be statistically similar (Table 4). Odor/ Aroma of BPB-Onions was significantly (p ≤ 0.05) higher than BPB flatbreads. These values for BPB-Garlic and BPB-Ginger were similar as BPB and BPB-Onions flatbread. Taste/Flavor of the BPB-Onions and BPB-Garlic to be similar and significantly better than BPB-Ginger and BPB flatbreads. These values for BPB-Ginger were also significantly higher than BPB flatbreads. The acceptance of the flatbreads tested was BPB-Onions 79%, BPB-Garlic 78%, BPB 68% and BPB-Ginger 66%.

a Values (mean ± SEM) within columns with different letters differ significantly (p ≤ 0.05), n=77.

bSensory evaluation parameters were on a scale of 1-5 (Like very much = 5, like slightly = 4, neutral = 3, dislike slightly = 2 and dislike very much = 1); Acceptance was on scale of 1-2 (Acceptable = 2 and Unacceptable = 1).

The desirability index for sensory parameters was calculated as percent of tasters judged [like very much + like slightly + ½ (neutral)], Kahlon et al. [13,14]. Desirability index for BPB, BPBOnions, BPB-Garlic and BPB-Ginger flatbreads was for color/ appearance 86, 81, 83 and 85%; for odor/aroma 79, 88, 84 and 83%; for taste flavor 53, 85, 76 and 70%; for texture/mouth feel 67, 57, 65 and 64% respectively. The aim was to achieve desirability index ≥70%. Data suggest that Taste/Flavor of BPB and Texture/ Mouth feel of all the flatbreads tested needs to be improved.

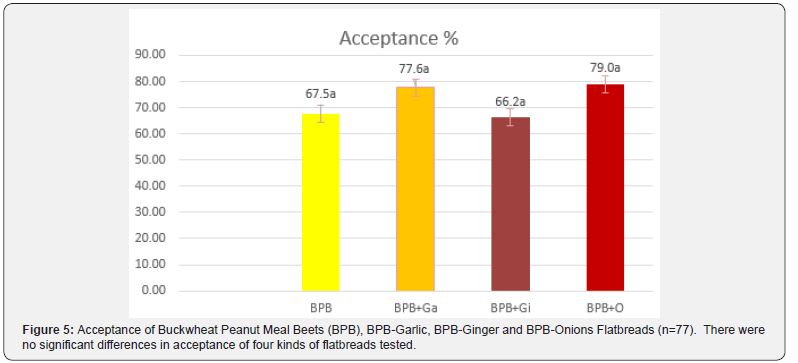

Percent acceptance of the ancient whole grain, gluten-free, Buckwheat Peanut Meal Beets flatbreads is given in Figure 5. Acceptance of flatbreads tested was BPB (68%), BPB-Garlic (78%), BPB-Ginger (66%) and BPB-Onions (79%). Acceptance values for the four kinds flatbreads tested were statistically similar. The objective of attaining acceptability ≥70% was achieved in BPBGarlic and BPB-Onions, however it was 2-4% short in BPB and BPB-Ginger flatbreads. All the sensory parameters in BPB-Onions and BPB-Garlic flatbreads were preferred by the tasters.

Values (mean±SEM) within columns with different letters differ significantly (p ≤ 0.05), n=77.

Water activity (Aw) was measured (N=3) at 25.01 ± 0.02 °C by AquaLab dew point water activity meter 4TE (Decagon Devices, Inc., Pullman, WA).

True density (ρt) was determined (N=5) by AccPyc II 1340 gas pycnometer (Micromeritics Instrument Co., Norcross, GA) at 21.4 ± 0.4 °C.

The bulk density (ρb) of each sample was measured (N=3) by Ottawa Sand volume displacement by about 10g of sample in triplicate after 15-5-5 minutes shaking in a jar of 202 cc volume.

Porosity was calculated using the equation [Porosity = 1 – (ρb / ρt)].

Expansion was calculated using the equation [Expansion = (ρt/ ρb)].

Water activity (Aw) and true density (ρt) of the four kinds of flatbreads tested were statistically similar and the values ranges (0.96-0.97) and (1.30-1.32), respectively (Table 5). Most spoilage molds, yeasts and bacteria could grow on foods with Aw of 0.80, 0.88 and 0.90, respectively, Water Activity, Safe foods 360 [27]. The flatbreads tested had similar Aw as observed in Cheese (0.97), salad dressing (0.97-0.98), fresh meat (0.98), US Food & Drug Administration (FDA) Inspection Guides [28]. Aw test data suggests that these flatbreads were chewy and should be preferably served freshly cooked. They could be stored in refrigerator up to three days. These uncooked flatbreads were vacuum sealed after flushing with nitrogen and stored in the freezer using zip lock bags. After six months these flatbreads were thawed to room temperature and cooked as described earlier. No adverse effects in sensory parameters were observed by consensus of the laboratory personnel.

Bulk density (ρb) was significantly lower for BPB-Onions flatbreads than BPB-Garlic, BPB and BPB-Ginger. These values for BPB and BPB-Ginger were similar and significantly lower than BPB-Garlic flatbreads. ρb values were BPB-Onions (0.47) < BPB = BPB-Ginger (0.51) < BPB-Garlic (0.55). Porosity and Expansion for BPB-Onions were significantly higher than BPB, BPB-Ginger and BPB-Garlic flatbreads. These values for BPB and BPB-Ginger flatbreads were similar and significantly higher than BPB-Garlic. Data suggest that BPB-Onion flatbreads were chewy, softer and fluffier. For BPB-Onions, BPB, BPB-Ginger and BPB-Garlic, Porosity and Expansion values were 0.64 and 2.81; 0.61 and 2.55; 0.62 and 2.57 and 0.59 and 2.40, respectively.

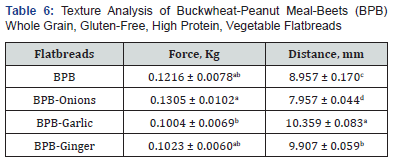

Values (mean±SEM) within columns with different letters differ significantly (p ≤ 0.05), n=10.

The texture analysis revealed that BPB-Onion flatbreads required significantly more force to rupture than BPB-Garlic flatbreads (Table 6). For BPB and BPB-Ginger rupture force was similar as other flatbreads tested. Distance travelled to rupture was significantly different among the four kinds of flatbreads tested. The values were BPB-Garlic > BPB-Ginger > BPB > BPBOnions. Data suggest that strechability of the flatbreads tested was inversely proportional to the force required to rupture. The tests were highly repeatable (n=10). There were greater and significant differences in the rupture distance, however the force required to rupture had less variability among the flatbreads tested.

The acceptability of whole grain, gluten-free, high protein, vegetable, flatbreads tested was statistically similar (Figure 5). Acceptability value were BPB (68%), BPB-Garlic (78%), BPBGinger (66%) and BPB-Onions (79%). The objective of the study was to achieve ≥70% acceptability for the whole grain, gluten-free, high protein, vegetable, nutritious, tasty, flatbreads containing health promoting phytonutrients. This objective was clearly attained with BPB-Onions and BPB-Garlic flatbreads as it exceeded by 8-9%, whereas it needs to be improved in BPB and BPB-Ginger by 2% and 4%, respectively.

Conclusion

The flatbreads containing Buckwheat Peanut Meal Beets (BPB), BPB-Onions, BPB-Garlic and BPB-Ginger were evaluated. The objective was to make whole grain, high protein, vegetable, health promoting flatbreads. The aim was to add value to low value peanut meal a farm byproduct and have gluten-free, 25% protein, vegetable flatbreads with ≥ 70% acceptability. The acceptance of the flatbreads tested was BPB-Onions 79%, BPBGarlic 78%, BPB 68% and BPB-Ginger 66%. The objective of acceptability was clearly met (exceeded by 8-9%) in BPB-Onions and BPB-Garlic flatbreads and protein level attained as 22-23% was nearly met (only short by 2-3%). These flat breads used only 3-4 ingredients and could be made in any house kitchen or by commercial production. It will add value to low value farm byproduct peanut meal. These high protein, gluten-free, whole grain, vegetable flatbreads offer nutritious, tasty and healthy choice to all and those sensitive to gluten.

To

Know More About Nutrition & Food Science International Journal Please Click

on:

https://juniperpublishers.com/nfsij/index.php

To Know More About Open

Access Journals Publishers Please Click on: Juniper

Publishers

No comments:

Post a Comment