Current Trends in Biomedical Engineering & Biosciences - Juniper Publishers

Abstract

In this paper, sensor based on surface acoustic waves for ethanol vapors detection, was fabricated and studied. For room temperature detection of the volatile compound, a novel carbyne nanofilm was deposited on the surface of a SAW transducer. The conventional electrodes were replaced by conductive polymeric coting of poly(3,4-ethylenedioxythiophene):poly (styrenesulfonate) (PEDOT:PSS) to minimize the microstructural and elemental difference between the electrode and gas sensitive material. The experimental results showed that the sensors had a good response to ethanol at room temperature. The maximum response of the sensors was at 600 ppm, where the time delay between the output and the input signals of the transducer was ~ 160 μs. The parasitic contact resistance and interface capacitance were found insufficient to affect the accuracy of the measurement, although their values are higher as compared to the sensors with metal electrodes.

Keywords: Ethanol sensor; Organic materials; PEDOT:PSS; Surface acoustic waves; Synchronous changes

Abbreviations: SAW: Surface Acoustic Wave; QCM: Quartz Crystal Micro Ballance; IDT: Interdigitated; EIS: Electrical Impedance Spectroscopy

Introduction

The constant drive for advancements in sensing technology has led to the development of ethanol sensors that leverage surface acoustic wave (SAW) detection principles. Ethanol sensing is a critical area of research with applications ranging from breath analyzers for alcohol detection to critical medical conditions monitoring. Tracking ethanol levels in the environment helps in assessing air quality, tracking pollution sources, and implementing measures to mitigate the impact of ethanol on air quality and public health [1].

Electrochemical sensors utilize the changes in electrical properties (such as current or voltage) of an electrode surface upon interaction with ethanol molecules. These sensors offer high sensitivity and selectivity, making them suitable for real-time ethanol monitoring applications [2]. Infrared spectroscopy relies on the absorption of infrared radiation by molecules, including ethanol, to determine their presence and concentration [3]. Ethanol molecules exhibit characteristic absorption patterns in the infrared spectrum, allowing for accurate identification and quantification of ethanol in a sample. Quartz crystal microballance (QCM) sensors utilize the piezoelectric properties of quartz crystals to detect changes in mass or viscosity that occur upon adsorption of ethanol molecules on the crystal surface [4]. The frequency shifts in the crystal resonator at the presence and concentration of ethanol in the sample. By utilizing SAW technology, which relies on the conversion of electrical energy into mechanical waves along the surface of a piezoelectric substrate, it is aimed to achieve improved sensitivity, selectivity, and response times in ethanol detection.

While some of the early mentioned sensor architectures are complex and expensive, requiring skilled operators and sophisticated instrumentation. SAW sensors offer a simpler design, cost-effective fabrication, and ease of integration, making them more accessible and practical for widespread deployment [5]. Techniques like IR spectroscopy and mass spectrometry may have longer response times due to sample preparation steps and analysis requirements. SAW sensors typically offer rapid response times, enabling real-time monitoring of ethanol concentrations with minimal delay. Instruments based on certain detection principles, may lack portability and require laboratory settings for operation. SAW sensors are often compact, lightweight, and suitable for on-site or field applications where portability is essential. Certain sensor architectures may be prone to drift, signal degradation, or calibration issues over time, impacting the long-term reliability of the sensor system. SAW sensors can exhibit high durability, stability, and reproducibility in detecting ethanol concentrations, ensuring consistent performance and minimal maintenance requirements.

The use of organic materials offers advantages such as biocompatibility, low-cost fabrication, and potentially higher sensor performance compared to traditional inorganic counterparts. Organic materials typically have tunable properties, such as conductivity, permittivity, and mechanical characteristics. The manufacturing processes for organic materials can be simpler, more scalable, and potentially more cost-effective, making the production of sensors more accessible and economical [6]. Organic materials may exhibit lower levels of interference from background signals or cross-reactive compounds, leading to improved selectivity in ethanol sensing. This reduced interference can enhance the sensor’s ability to distinguish ethanol from other compounds, contributing to more reliable and accurate detection results. Carbyne, a one-dimensional allotrope of carbon with remarkable mechanical and electronic properties, has attracted significant interest in the field of sensor technology as a sensing layer. Due to its ultra-thin structure composed of sp-hybridized carbon atoms arranged in a linear chain, carbyne exhibits exceptional strength, stiffness, and tunable electrical conductivity, making it an intriguing candidate for enhancing sensing capabilities in various applications [7]. Bottom-up approaches, such as molecular self-assembly or surface-assisted synthesis, can be employed to build carbyne structures layer by layer on a substrate. By carefully manipulating precursor molecules or atoms, researchers can guide the formation of carbyne thin films with controlled properties. It has been demonstrated its sensitivity toward organic volatile compounds, which makes the carbyne preferable candidate for biomedical engineering and health-care applications [8].

Metal oxide semiconductors such as tin oxide (SnO2), zinc oxide (ZnO), and tungsten oxide (WO3) are widely used as sensing layers in gas sensors. These materials exhibit changes in electrical conductivity in the presence of target gases, enabling the detection and quantification of gases like nitrogen dioxide (NO2), carbon monoxide (CO), and volatile organic compounds (VOCs) [9]. Conductive polymers like polyaniline, polypyrrole, and polythiophene are employed as sensing layers in chemical and biological sensors. These polymers undergo changes in conductivity or optical properties upon interaction with specific analytes, making them suitable for detecting gases, humidity, pH levels, and biological molecules. Poly(3,4-ethylenedioxythiophene): poly(styrenesulfonate) (PEDOT:PSS) is a conductive polymer composite commonly used as an electrode material in sensors due to its excellent electrical conductivity, transparency, flexibility, and stability. PEDOT:PSS is biocompatible and non-toxic, making it ideal for interfacing with biological systems in biosensors and medical devices [10]. Its biocompatibility reduces the risk of adverse reactions or tissue damage when used in implantable sensors or diagnostic tools. The surface properties of PEDOT:PSS can be tuned by modifying the composition, doping level, or surface treatment of the polymer, allowing for tailored interactions with specific analytes or target molecules in sensors. This tunability enhances the sensitivity and selectivity of PEDOT:PSS-based sensors.

In this paper, a novel approach that incorporates organic materials such as PEDOT:PSS patterned through the lift-off technique for improving the sensor’ environmental and cost effectiveness, was developed and studied. Through this work, it was explored the feasibility and effectiveness of organic materialpatterned SAW devices for ethanol sensing applications. The novelty lies in the specific combination of organic material electrode patterning through lift-off, because normally the resolution of patterning cannot exceed few hundred micrometers, because the organic solutions are often ink-jet printed or spray coated with no need of patterned. However, this is not the case of SAW, where the electrode topology must be interdigitated (IDT) with defined lower size and shape features to avoid measurement errors and information losses. Being of the same classes – organic materials – carbyne and PEDOT:PSS have similar thermal and mechanical characteristics. Thus, during heating with a microheater for initial measurement conditions restoring, due to their close thermal coefficient of expansion, the interface stress is expected to be minimal, which will contribute to the long-term reliability of the sensor devices. In addition, if the technology is translated to wearable and the films grow on a flexible substrate, their mechanical stability will enhance the device durability.

Materials and Methods

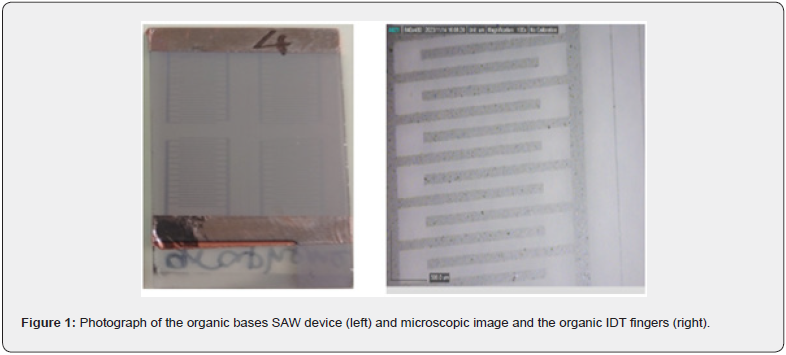

Quartz substrates were immersed in acetone cleaning solution in supersonic bath and dried with ethanol vapors. The substrates were ozone treated for adhesion promoting of the next layer. Ultrathin gold film (12 nm) was vacuum DC sputtered on the quartz substrate and patterned by conventional photolithography with inverse image of regarding the SAW IDT electrode fingers. This film will serve as a sacrificial for transferring the pattern into the organic electrode. The deposition sequence and conditions for carbyne film fabrication are presented elsewhere [11]. PEDOT:PSS thin film was sprayed on its top, afterwards, the gold underlayer was lifted off in potassium iodide etching solution, which is not aggressive to the organic film. The optimized atomizing conditions was set, like spraying pressure of 4 bars, spraying angle of 45o and nozzle - substrate distance of 8 cm at temperature of pulverization of 105 oC. Photograph of the organic bases SAW device and microscopic image and the organic IDT fingers, are shown in Figure 1 left and right, respectively. Electrical impedance spectroscopy (EIS) was conducted by Hioki Impedance analyser IM3590 in the frequency range from 1Hz to 200 kHz. Testing of the signal transducing at different ethanol vapor concentrations was realized by signal generator up to 20 MHz and the output waveform voltage was monitored with a digital storage oscilloscope DQ2042CN with a frequency bandwidth up to 50MHz. A lab-made chamber with controlled environment was used, which accommodates the measured device and commercial hygrometer reading the amount of water vapor present in the air in percentage.

Results and discussion

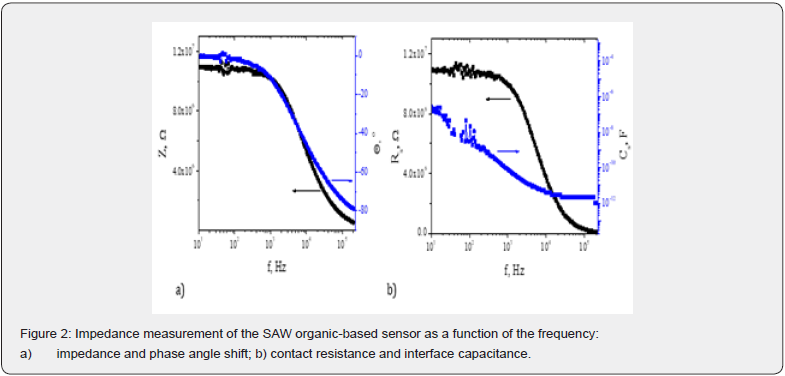

A decrease in impedance by one order of magnitude around 1 kHz in the surface acoustic wave-based sensing device can result from resonance effect (Figure 2a). The observed frequency of 1 kHz may coincide with a resonant frequency or a critical point in the device’s impedance-frequency response curve. At resonance, the impedance can decrease sharply, indicating that the device is most responsive or efficient at that specific frequency. Due to the lower conductivity of the electrode material as compared to the metals, the impedance of the device is in MΩ range. The quality of electrode deposition, adhesion to the substrate, and uniformity across the device’s surface can influence impedance levels. Poor electrode adhesion or non-uniformity can introduce noisy curves with multiple ripples. The stability of the impedance curve in each frequency range is an indication for the presence of a uniform electrode and sensing layers, as well as stable contact in between. The synchronous changes in phase angle shift and impedance at a specific frequency could indicate a resonant behavior of the device at that frequency. Electrodes may introduce parasitic effects, such as stray capacitance, which may interfere the impedance matching process.

As is seen in Figure 2b, there is only serial interface capacitance, which is in the expected range and decrease from nF to pF with the frequency increase. The presence of interface states or contaminants at the contact interface can impact resistance properties and introduce frequency-dependent behavior. At higher frequencies, the effects of interface states, or surface impurities may become more pronounced, contributing to contact resistance variations. It may due to the incomplete lift-off the sacrificial layer during the organic electrode patterning. Overall, the SAW line is in working condition with negligible distortions of the signals that can be ascribed to the non-conventional choice of electrode material and the adapted technology for its patterning.

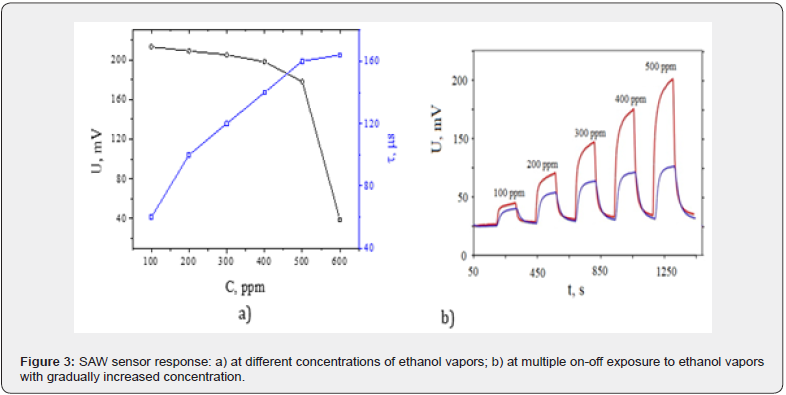

Voltage differences between the output and input signals of the SAW and time delay of the signal vs. ethanol concentration is shown in Figure 3a. According to the mass-loading conditions (concentration changes), the output voltage of the SAW line attenuates and the signal delays proportionally to the increased density on the path of the elastic wave’s propagation. The sensor is relatively linear in the range 100-500 pm and exhibited a sensitivity of 40μV/ppm. In the range 500-600 ppm the sensitivity increased to 1.4mV/ppm. This increased mass loading leads to a greater change in the sensor’s resonant frequency, resulting in a more pronounced shift that enhances sensitivity. Higher ethanol concentrations lead to a more complete and dense coverage of the sensor surface by ethanol molecules. This higher surface coverage increases the sensor’s response to ethanol and enhances sensitivity by producing a more substantial change in the detected signal. In SAW devices, acoustic waves propagate at a constant velocity along the surface of the substrate. This fixed propagation speed ensures that the time delay between signals remains consistent and linear, making time-based measurements more reliable and predictable compared to voltage-based measurements, which can be influenced by signal amplification or attenuation.

In addition, time-based measurements in SAW sensors may exhibit greater noise robustness compared to voltagebased measurements. The distinct time delay responses are less susceptible to noise interference and variations, allowing for more accurate and sensitive detection of signal differences. Therefore, on the same plot, the time delay between the signals in microseconds is also presented as a measure for concentration detection. Figure 3b shows the dynamic responses of all sample sensors to 100-600 ppm ethanol at an operating temperature equal to the room temperature. By increasing vapors concentration, the sensors are still able to recover to the initial state. As compared to previously studied SAW ethanol sensors with metal electrodes, the fabricated full organic-based sensor device is able to detect in the same concentration range, at similar time delay sensitivity of average 0.26μs/ppm vs. 0.23μs/ppm for the metal electrodes. This is a proof for successful realization of workable ethanol vapor sensor that can be used for close to realtime measurements determining the health condition of patients. The sensors demonstrate negligible hysteresis and restores its initial conditions after shading their surface from ethanol vapors. The devices are relatively inert and their response and recovery times varied from 40s and 50s at low concentration to 50 s and 70 s at higher concentrations beyond 300 ppm. As a modified electrode has lower conductivity, which cannot accelerate the transfer of charge carriers, the response time and recovery time are increased, as compared to the typical values of 10-20 s for SAW mechanism.

Conclusion

In summary, PEDOT:PSS nano coatings were successfully prepared by a spray deposition method and the prepared SAW sensor was applied to the vapor sensing test of ethanol. The samples achieved a response of 100-600 ppm at room temperature, with relatively linear concentration response in the range of 10–500 ppm ethanol vapors. In addition, the sensor had satisfactory time parameters (the response time and recovery time to 100 ppm at room temperature were 40 and 50 s, respectively).

To Know more about Current Trends in Biomedical Engineering & Biosciences

Click here: https://juniperpublishers.com/ctbeb/index.php

To Know more about our Juniper Publishers

Click here: https://juniperpublishers.com/index.php

No comments:

Post a Comment