Robotics & Automation - Juniper Publishers

Abstract

In this work, we present the Bio- Environmental Engineering scaling laboratory; that is located in Los Reyunos, Regional Development Technology Center. Its objective is the scaling of concept proof to pilot or prototype test for technology transfer suitable in real environments. We suggest the laboratory as an automatized Technological Demonstrator that allow us to adapt the work conditions making possible that the technology scope the degree of innovation with TRL 6. That scale test allows to know the parameters to apply in the territory mainly about ph, Eh, inlet flow, bioremediation system, kind irrigation, relationship between cycles.

Keywords: Module depuration vegetable; Engineering scaling; Bio-Environmental laboratory; TRL 6; Design processes’ cycles

Bio-Environmental Laboratory

The laboratory consists of two pools. Each pool has a width of 2.8m, a length of 5m, and a depth of 0.6m with 6% slope, both are connected by a hydraulic system to effluent collector chambers. The system has reservoirs for the entry of water, a main system where the water runs by a vertical or horizontal flow, waterproofing and nylon covers. Its automatic hydraulic system allows:

a) to regulate the entrance of water by vertical and/or horizontal system;

b) to recycle effluents and

c) to design processes’ cycles in series or parallel of vertical or horizontal flow systems (Figure 1).

Ibañez [1] emphasize that first three levels (TRL 1-3) approach the most basic technological research until reaching into the first proof of concept. The Technological Development is carried out to the following levels from a first prototype (TRL 4-6). The TRL 6 sets the validation of the system or the subsystem in relevant environment while TRL 7 sets the validation and a certification in a real environment. Through this laboratory, it is possible technology to reach into the tests in a real environment.

Cases Bio-environmental Laboratory

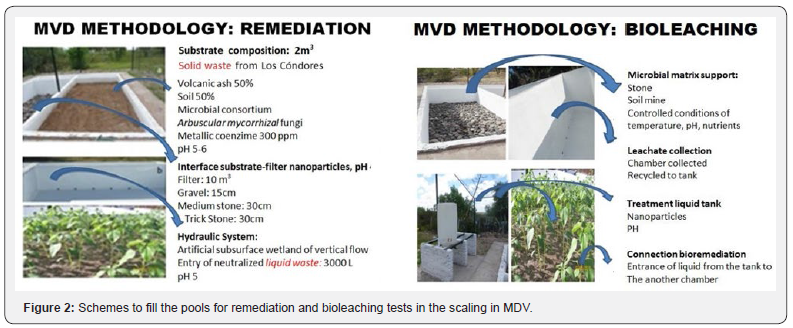

Two situations of engineering scaling are exposed in the environmental biotechnology areas. In the first instance is a vegetable depuration module (VDM) for phytoremediation of soils and waters contaminated with heavy metals, developed in a PID FRSR UTN and the second case is about bioleaching and bioaccumulation pools to value bacterial consortiums, in development by an ERA MIN European Union. Scheme of processes and the function the pools are shown in the Figure 2.

Case 1 vegetable depuration module (VDM)

In this case, was possible to scale, from TRL 3 to TRL 6, a bioremediation system of soils and contaminated waters with heavy metals to be transfer to the industry. The Technological Transfer of the pilot test (TRL 6) was applied to the National Atomic Energy Commission and to the environmental company GT. The Figure 1 Part B shows the scheme of phytoremediation and one of the pools with the bioremediation system [2]. It was obtained the calibration system to be applied in the territory. The technological bases used involve the performance of the artificial wetlands of vertical flow modified in the volume of the substrate, the time of hydraulic retention and the bioremediation system is based on the mycorrhiza symbiosis of hyper-accumulators’ species [3,4].

Case 2 bio critical metals

The BioCriticalMetals is an international project with the participation of the public sector (Universities) and the private sector (mining companies) of Portugal, Romania and Argentina, supported by ERA MIN European Union. One of the tasks of the FRSR through the Environmental Laboratory is to scale the results of bacterial consortiums of bioleaching and bioaccumulation of tungsten from tailings soils in the Los Cóndores, the San Luis mine. The scaling diagram includes the two pools, in one the soil is disposed with the bioleaching consortium, the effluent with the tungsten is collected in the collection pool and transported to the second pool where the bioaccumulation consortium is placed. The residues of both processes are treated with zero valent iron nanoparticles and phytoremediation (Figure 2).

Conclusion

Our results indicate that we were able to design two work schemes to make the scaling to TRL 6 of two research projects. In the first MDV, the calibration of the engineering scaling was carried out. The calibration consisted in to determinate the value of the following parameters: inlet flow, time retention hydraulic, outlet flow, number of mychorrized plants, time of test, pH, Eh, kind of irrigation and balance mass to each metals tested, In the second case, the BioCriticalMetals is being adapted to scale (TRL 4) as a previous step to engineering scale (TRL 6).

To Know more about Robotics & Automation

Click here: https://juniperpublishers.com/raej/index.php

Click here: https://juniperpublishers.com/index.php

No comments:

Post a Comment