Insights in Mining Science & Technology - Juniper Publishers

Introduction

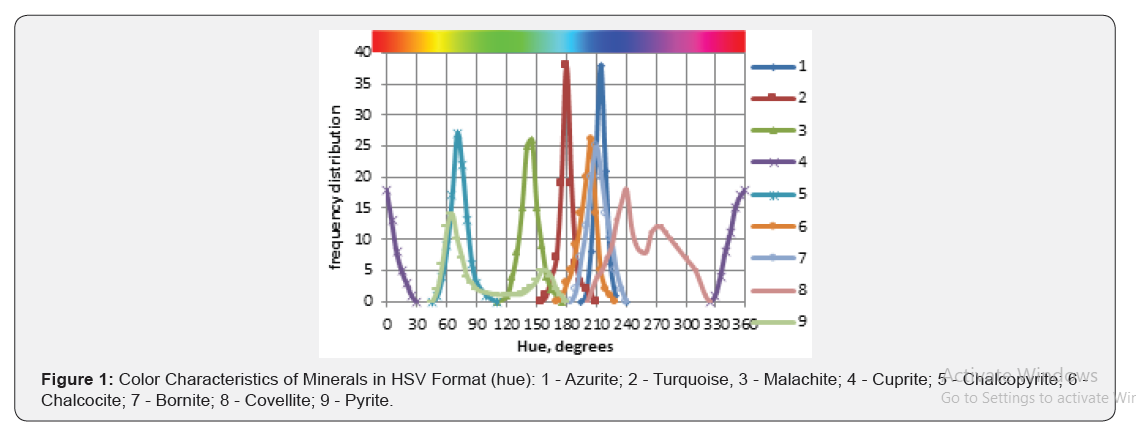

In-stream ore grade analysis is a new trend in

effective control of ore benefication processes. On-line estimation of

ore grade can be implemented based on continuous measurement of the

mineralogical composition directly in-stream or using in-stream sampling

with the following analysis. Reliable separate determination of

minerals in ore is possible using modern formats of colour image

recognition. The spectral characteristics of minerals in visible light

are the source of information for optical spectrum-based estimation of

ore mineralogical composition (Figure 1). The task of determining the

grade of ore, entering processing, is to determine its similarity to the

main technological types of ores [1]. The calculation of ore grade was

carried out using a multi-criteria method for affiliation shares

calculations.

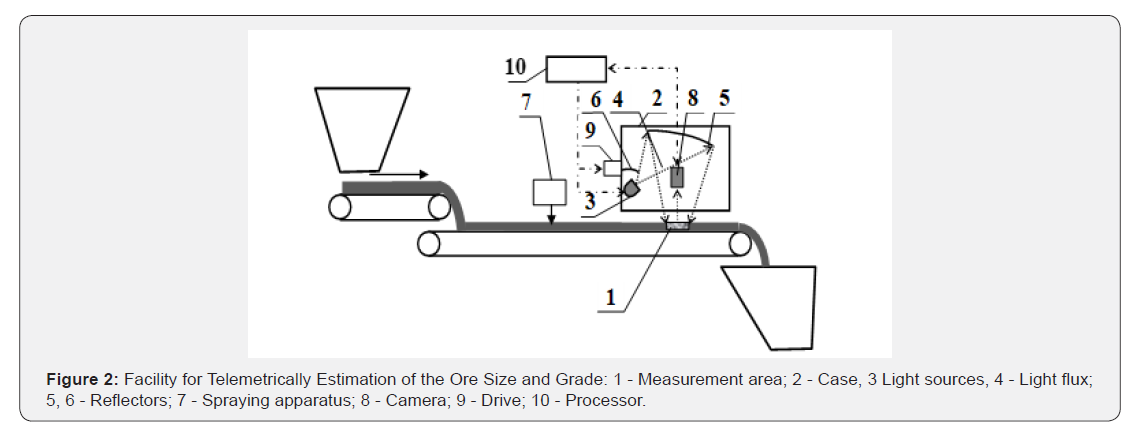

The system mathematical model provides for calculation of the incoming

ore affiliation by six (or more) significant parameters (minerals

contents in the ore). At the Erdenet processing plant (Mongolia), a new

facility for advanced ore diagnostics, based on optical analyzer of

mineral composition, was tested. The optical spectrum-based analysis

system was installed above the conveyor (Figure 2) for feeding ore to

the grinding operation [2]. The ore scanning on the conveyor belt is

carried out continuously. Then, using the algorithm, recognition of the

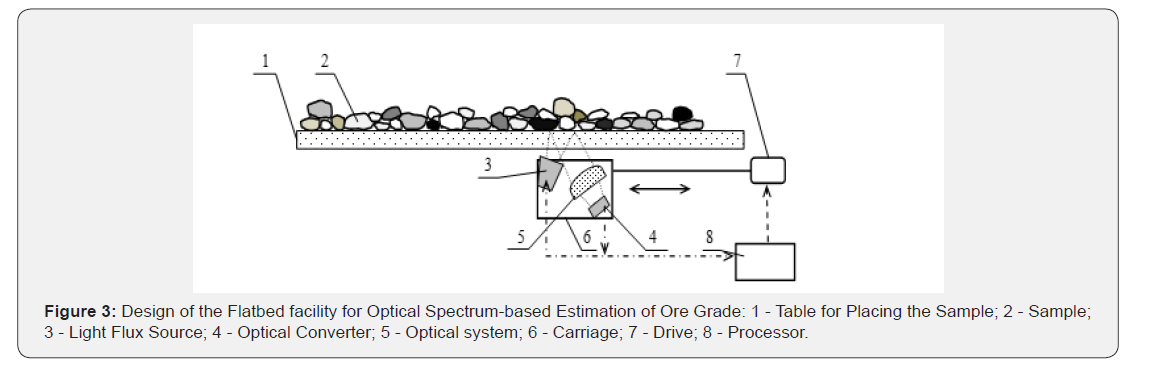

ore grade is carried out. For exact analysis, the special flatbed

facility was developed [3]. The measurement technique involves preparing

the ore sample, forming the measurement area in the form of a flat

portion of the sample, illumination and capture of the images in the

visible spectrum (Figure 3).

To calculate the required parameters of grinding and flotation,

special studies were carried out on the most pronounced samples

of the typical ores, and the process diagrams for their grind

ing and flotation were developed. The value of the pre-set function

SF for each parameter of the process was calculated as a

weighted average of the parameters values for each “typical” ore

type (SFi) considering the contribution of the given type in the

ore’s mixture using Equation (1):

where γi - relative weight fraction of an ore type in the ore

mixture incoming to processing. The predefined functions were

used as baseline in the local systems of automatic control of

grinding and flotation processes at the Erdenet processing plant.

Using the procedure for ore grade determination increases the

automatic control stability, as it allows a fast response to changes

in the incoming ore grade. Maintaining the optimum degree

of grinding and reagent consumption in the flotation provides

increasing recovery of copper and molybdenum into concentrates

by 0.3% and 1.1%, respectively, as well as decreasing the

consumption of reagents by 2–3% [4].

To Know more about Mining Science & Technology

Click here: https://juniperpublishers.com/imst/index.php

To Know more about our Juniper Publishers

Click here: https://juniperpublishers.com/index.php

It is really good article and it will be helpful for a Engineering Students for final year projects to make a Digital Image processing projects

ReplyDelete