Recent Advances in Petrochemical Science - Juniper Publishers

Abstract

Carbon dioxide is a non-flammable, inexpensive and

non-corrosive substance that due to its properties is a suitable solvent

for supercritical fluid extraction.co2 critical temperature

is 31.06oC and its critical pressure is 7.386MPa. Due to its low

critical temperature, thermal degradation of food components is not

occurred. For extraction of compounds with high molecular weight,

supercriticalco2 extraction is a suitable technology. In dairy processing industry, supercriticalco2

extraction, in comparison to pasteurization process, has vast

applications, such as using as enzymatic and microbial inactivation

agent; producing bicarbonates, carbonic acid and hydronium in milk

carbonation reduced liquid production, extraction and fractionation of

fat and cholesterol by which, higher quality products and solvent free

residues were produced. On the other hand, supercriticalco2

technology systems have the advantage of operating as batch,

semi-continuous and continuous mode. In this research, different

applications of supercriticalco2 extraction for some dairy products are reviewed in detail.

Keywords: Supercritical carbon dioxide Dairy product Extraction Green solvent

Abbrevations: PAA: Peracetic Acid; SCT: Short-Chain Triglycerides; MCT: Medium Chain Triglycerides; LCT: Long-Chain Triglycerides

Introduction

In supercritical fluid extraction, under certain

temperature and pressure, as some chemicals are good solvents for some

solutes, the required extraction happened. For each solvent, above its

critical pressure and its critical temperature, it becomes

supercritical. CO2 critical temperature is 31.06oC and its critical pressure is 7.386 MPa. CO2

as a non-flammable, non-corrosive and inexpensive substance is a proper

solvent for supercritical fluid extraction. On the other hand, as CO2

critical temperature is low, thermal degradation of food components

during extraction is prevented [1]. For extraction of compounds with

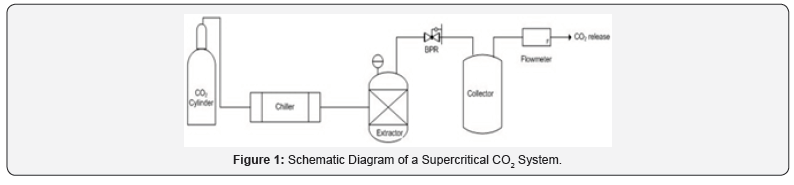

high molecular weight, supercritical CO2 extraction is a suitable technology (Figure 1). This system has CO2

pump, pressure regulator, a chamber for keeping the sample, anda

collecting vessel. A heating zone is also required in which the liquid

would be heated to supercritical condition and subsequently for

solubilizing the sample to diffuse into it. From extraction column,

dissolved material is sent to separator and extracted part was settled

out. In the last stage, carbon dioxide is cooled, recompressed and

discharged to atmosphere or recycled to the process [2]. In the food

industry, supercritical CO2 is an ideal solvent; as it is

inert, cheap, available, odorless, tasteless and safe solvent. Due to

its near ambient critical conditions, supercritical CO2 is an appropriate choice for thermo-labile and

non-polar natural products. In comparison to pasteurization process, in dairy industry, supercriticalco2 process has various applications; it is suitable for reduction in microbial substances. As a consequence, a product with better shelf life and greater

organoleptic properties would be obtained.

Dairy Products

Dairy products are consumed all around the world. Due to

their high nutritional value, they were considered as healthy

choices. It is predicted that by 2024, approximately 36%

increase in global consumption of different dairy products

would be observed [3]. In order to have safe milk consumption

and stable shelf-life, milk must undergo thermal processing. As

conventional high-temperature processes may lead to change

in nutritional and organoleptic characteristics, in recent years,

alternative non-thermal technologies are required; such as

supercritical carbon dioxide. In order to destroy microorganisms

(while keeping nutritional content), supercritical carbon

dioxide technology is used. Although due to high equipment

and operational cost, industrial application of supercritical

processes could be an obstacle [4-6].

In conventional food/medicine pasteurization process,

bioactive compounds may be destroyed by conventional

thermal process. In the food industry, various compounds at

their supercritical state were used; the most common one is

CO2. By reducing pressure, it can be omitted from food matrix

and be circulated to the system. This is the main reason that

supercritical CO2 technology is known as an environmentally

friendly one. Due to low critical temperature of CO2 this technology can

be used near room temperature which minimizes any probable

changes in the nutritional and physicochemical characteristics

of food and prevents degradation of thermosensitive and volatile

compounds. Moreover, as CO2 has moderate critical pressure,

minor investment costs are required for this process. In dairy processing, supercritical CO2 technology has many

applications; such as [7-11]:

a. Using as enzymatic and microbial inactivation agent.

b. Producing bicarbonates, carbonic acid and hydronium

in milk carbonation reduced liquid production.

c. Extraction and fractionation of fat and cholesterol by

which, higher quality products and solvent free residues

were produced.

Supercritical CO2 technology systems have the advantage of

operating as batch, semi-continuous and continuous mode. An

effective contact between CO2 and dairy sample was occurred

in semi-continuous and continuous systems. As CO2 saturation

is very rapid, enzymatic and microbial inactivation was more

effective; as a consequence, operating time and manufacturing

costs were reduced. CO2 pump and pressure regulator are main

compartments of a batch system. An exhaust system is also

implemented to release the pressure after the process. For

controlling the cooling or heating temperature, a temperature control apparatus is established which could be a water bath,

oven or autoclave. In semi-continuous process, vessels are

connected in series; some of them are pressurized and the rest

are in constant pressure. In this configuration, processing time

was reduced, and energy recovery was allowed. In continuous

apparatus, dairy sample and CO2 is mixed and passed through

the high-pressure pump. Praxair developed a high-pressure

CO2 pilot plant for milk treatment at different temperatures,

pressures and CO2 concentrations.

Cheese

As CO2 can have influence on the quality of semi-hard

cheese, current researchers were focused on its use in modified

atmosphere packaging. Recently, the effect of ripening condition

and composition on CO2 solubility was studied [12]. It was

observed that in temperature range of 2-25oC, there is a linear

relation between CO2 solubility and temperature. Moreover, salt

content was increased from 0 g/100 g to 2.7 g/100 g, by which

CO2 solubility was decreased. On the other hand, fat content has

influence on CO2 solubility coefficient [13] which confirmed

that CO2 has effect on aqueous and fat phase, for the latterco2

solubility was increased with temperature. Another application

of supercritical CO2 technology is for microbial growth control

in mozzarella cheese. Using 100ppm of peracetic acid (PAA) in

combination with supercritical CO2, yielded maximum reduction

of Geobacillus stearothermophilus spores. As mozzarella cheese

has worldwide popularity and consumption, these findings have

vast application for the cheese industry [14]. Supercritical CO2

technology is also applicable in low-fat cheeses production; such

as Cheddar and Parmesan [15,16] and Gouda-type [17]. Cheese

matrix, temperature, pressure and CO2 mass flow are important

parameters that affect lipid removal.

Milk

Different researchers studied supercritical CO2 technology

effects on milk properties. For food products, supercritical CO2

technology reduced the pasteurization or sterilization time and

minimized thermal degradation of thermo-labile compounds

(such as vitamins) [18]. It is worth mentioning that for milk,

its effect on vitamins degradation must be studied in detail.

Acidified milk, in comparison to heat-treated milk, showed

better preservation to retinol, 𝛼-tocopherol and 𝛽-carotene [19].

Due to acidification and solvation properties, supercriticalco2

affect milk protein as well; the probable mechanism for this

phenomenon is binding the obtained carbonic acid with calcium

ions [20].In the process of supercritical CO2 treatment of milk,

casein precipitation is an obstacle after which a dairy product

containing cheese would be obtained [21,22]. The precipitated

casein has industrial application. It was reported [21] that for

fractionation and precipitation of concentrated protein solution,

supercritical CO2 technology is a suitable method. All around

the world, whey beverage consumption is increasing [23,24].

It is reported [25] that whey proteins, in comparison to caseinare more resistance to high pressure and supercriticalco2

technology is capable of changing the structure of whey proteins.

Alkaline phosphate (as a milk endogenous enzyme) is used as a

criterion of effectiveness in milk pasteurization. Centi et al. [26]

used supercritical CO2 to inactivate alkaline phosphate in milk.

They studied the effect of pressure (8-18MPa), temperature

(30, 50, 70oC) and mass ratio ofco2 to milk (0.05 and 0.45

wt.%) during 30 min. At 70oC, 80 MPa and 0.45 wt.% the best

inactivation rate of alkaline phosphate was obtained as 98.2%.

This finding confirmed that supercritical CO2 technology is

applicable for alkaline phosphate inactivation in milk.

Roles of Supercritical Carbon dioxide

As shelf life improver

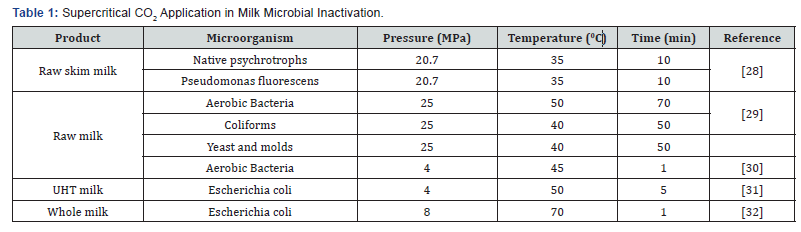

In 1987, for increasing shelf life of dairy products,

supercritical CO2 use was proposed [27]. In recent years, in dairy

(with emphasis on milk) products, the use of supercritical CO2.for microbial inactivation was studied (Table 1).

In dairy products, spore-former is an important

contaminant as it affects food quality. Moreover, it facilitates

product spoilage as it decreased its commercial shelf life [33].

The effect of supercritical CO2 on milk spore’s inactivation

was reported in some researches. Werner and Hotchkiss [34]

evaluated the existence of Bacillus cereus spores at different

operating conditions (i.e. temperature: 15, 30, 35 and 40oC;

pressure: 10.3, 24.1, 48.3 MPa; CO2 concentration 0, 3.66, 132 g/

kg milk). All researches proved that supercritical CO2 technology

has the ability to inactivate microbial contaminants in milk;

although milk fat content, bacteria age, equipment type, and

operating parameters are important factors that have influence

on microbial inactivation rate. Hence, in dairy production, for

the application of supercritical CO2 technology, the knowledge of

microbial inactivation mechanism is vital.

As cholesterol remover

Chitra et al. [35] used supercritical CO2 technology to

develop dairy product with healthier lipid profile. Temperature

(40-80oC) and pressure (15-25 MPa) were considered as

operating parameters; the optimum values for cholesterol

removal from whole milk powder were 68oC, 20.7 MPa, 6 lit/

min ofco2. Approximately 22.8% of cholesterol content was

removed, while free fatty acids, lightness amount and solubility

indicator were kept unchanged. In recent years, various

methods were investigated for cholesterol removal from foods

[36-38]; such as blending animal and vegetable fat with each

other, steam distillation, supercriticalco2 extraction, silica

gel- or carbon active- based adsorption, complexation with

𝛽-cyclodextrin, enzymatic treatment by cholesterol oxidase

and cholesterol reductase for cholesterol degradation and use

of cholesterol decomposing microorganisms such as Nocardia

and Rhodococcus. Among these methods, supercriticalco2

technology has various advantages, the most important of which

are high efficiency, rapid extraction fluxes, lower risk for thermal

product degradation, and higher nutrient retention [39,40].

It was reported that at moderate dynamic time increasing

operating pressure and decreasing extraction temperature

enhanced cholesterol removal [41-43]. For instance, increasing

pressure from 100 bar to 250 bar, cholesterol extraction wasincreased. On the other hand, by raising temperature from 40oC

to 57.5oC, cholesterol extraction was decreased and beyond

57.5oC a slight increase was observed in cholesterol extraction.

For dynamic extraction time, an increase from 2.5 h to 3 h

resulted in higher cholesterol extraction yield and from 3 h to

3.5 h yielded to lower insignificant cholesterol extraction yield.

As a concluding remark, for cream powder, optimum operating

parameters are 75oC, 204 bar and 3.5 h by which 39% reduction

in cholesterol content was observed [44].

As lipid fractionator and vitamin isolator

Supercritical fluid extraction is a technique for lipid

fractionation and vitamin isolation. It was reported that

supercriticalco2 technology is applicable to dairy products

for vitamins A and E removal from powder [45,46]. In order to

reduce the negative effect of water content of milk on extraction,

Berg et al. [45] tested Hydromatrix as a water adsorbent. As a

result, in 80min, from 0.5 g sample, all vitamins A and E were

extracted. Ramos et al. [47] used supercriticalco2 technology by

which milk fat was fractionated into four different parts; namely

short-chain triglycerides (SCT), medium-chain triglycerides

(MCT), long-chain triglycerides (LCT) and cholesterol. It was

found that polychlorinated biphenyls are predominantly in SCT,

MCT and cholesterol fraction of milk fat.

Yu et al. [48] reported the application of supercritical

CO2 technology for anhydrous milk fat. Milk fat obtained

by supercritical CO2 technology affected rheological and

physicochemical properties of butter. Shukl et al. [49] reported

that the resultant butter has lower moisture content and

cholesterol and higher melting points. In order to produce valuable substances that have industrial

application, supercritical CO2 technology is a good candidate

as it is capable of extracting lipophilic food compounds [50].

Moreover, supercritical CO2technology has the capacity to

effectively inactivate microorganisms [51].

Concluding Remarks

Supercritical fluid extraction as a green technology is

following all future regulations of health, safety and environment.

Supercritical fluid extraction has the ability to provide high

solubility, improved mass transfer rates and increased selectivity,

hence it has application in many industries. As a concluding

remark, in dairy industry, supercriticalco2technology is a good

option for keeping nutritional quality and inactivating important

enzymes. More research is needed to evaluate supercritical co2

influence on main intrinsic factors of dairy food processing such

as decreasing milk protein allergenicity.

No comments:

Post a Comment