Civil Engineering Research Journal

Abstract

Many developing countries are facing a lot of

challenges with management of huge quantities of solid waste generated

on daily basis. Plastic waste which is part of solid waste poses a

menace to sustainable development due to its slow rate of degradability

and the indiscriminate way it is disposed. To lessen the negative

impacts on the environment and the associated effects on human health,

plastic waste is being considered as materials in transition and are

being used in the production of pavement blocks and other materials for

construction purposes. The study reports some physical and mechanical

properties of plastic waste pavement blocks produced by one company in

Ghana which has taken a major lead in the direction of adding value to

plastic waste for construction. Results are compared to two other

pavement block types made from cement and fired clay pavement blocks and

discussed. Using plastic waste as transition materials for pavement

blocks may among other benefits listed, translate to reduction in

construction cost and large quantities of plastic waste polluting the

environment and may contribute to cleaner cities and towns.

Keywords: Plastic waste; Transition materials; Pavement blocks; Environment; Construction

Introduction

Economic growth and changing consumption patterns are

resulting in rapid increase in the use of plastics in the world. Thus,

consumption of plastic material has increased from 5 million tons in the

1950s to 100 million in the 2000s. In Ghana per capita generation of

plastic waste has been reported to be between 0.0016-

0.035kg/person/day. And, plastics make up between 18-20% component

materials in the waste stream [1]. There are however concerns about

plastic waste disposal methods commonly employed in many developing

countries as they do not deal effectively with the large tonnes of

plastic waste generated. These disposal methods include dumping plastic

waste in landfills, incineration and open littering. Since plastics take

several years to degrade, there are challenges associated with their

improper disposal which include:

i. Blocking drains and choking of gutters which may contribute to floods

ii. Release of toxic gases into the atmosphere when

openly burnt. Some of these gases may be harmful to humans and cause

greenhouse effects.

iii. Discarded bottles and containers may serve as breeding grounds for mosquitoes when filled with rainwater.

iv. Washing of the littered plastic materials into water bodies including oceans contributing to decline of ocean life.

Common pavement materials used in Ghana include the

cement pavement blocks and the fired clay pavement bricks. Portland

cement imported into the country is used in the production of cement

pavement blocks and is associated with increasingly high cost due the

unstable value of foreign exchange. Fired claypavers produced from

available local clay materials are not very popular with a lot of people

because they are perceived by many as expensive. The production of

fired clay pavers currently in the country relies on firewood burnt at

very high temperatures. This firing method is not sustainable and

associated with consumption of a lot energy. In recent times, due to the

ecological and environmental challenges associated with the disposal of

plastic waste, there are a lot of interest in turning plastic waste

into a resource in construction. Pavement blocks produced from waste

plastic and other materials like sand, quarry dust etc., is recently

being promoted in many developing countries as a more affordable and a

sustainable material which may be used in construction and Ghana is no

exception. Though it is generally known that these plastic waste

pavement blocks are strong and durable, there is little scientific data

in Ghana to support this claim. This paper therefore reports a study on

three types of pavement blocks produced from plastic waste, fired clay,

and cement with regards to some of

their physical and mechanical properties.

Materials and Methods

Materials

The pavements samples under study were obtained from

three different commercial paving factories in Ghana. The raw

materials used in the production of these pavers comprised of

cement, quarry dust and fine aggregates (sand), for the cement

pavers, clay for the clay pavers, and waste plastics and sand for

the plastic pavers. Six samples of each paver types were randomly

selected and tested for each of the various physical and mechanical

properties which include density, compressive strength, flexural

strength, abrasive resistance, water of absorption and durability

in sea water. Plastic pavement blocks were commercially

produced in bigger sizes of 30cm by 30cm. They were cut into 4

equal part with half remaining. And test run on samples of dimension

20cm by 10cm with a thickness of 5cm. This is to make sure

all types of pavement blocks have comparable sizes. Cement and

fired clay pavement blocks are of hexagonal shape and with dimensions

23cm by 14cm with thickness 5m and 20m by 10.5 with

thickness 6.5cm respectively. The samples were cured for more

than 28 days to ensure maximum mechanical strength development

before the various test were conducted.

Method

Antifungal resistance

Density: The density of the various paving bricks was

determined using Archimedes principle of water displacement.

Dry weights of various pavers were measured and fully immersed

in a tank containing water. The volume of water displaced was

measured for each pavement type, and the average volume of

water displaced was recorded for five samples each of the various

pavers. The densities of the various pavers were determined by

dividing the dry weight by the volume of water displaced [2].

Compressive strength: The compressive strength is the

most prioritized property to be achieved in the production of

paving bricks in almost every factory that is actively involved

in manufacturing of pavers [3]. Hydraulic universal testing

machine which has a maximum capacity up to 2500KN was

used to determine the compressive of the various pavers in this

study. The load was applied to the nominal area of the cement,

clay and rubberized pavers to determine the various compressive

strengths. The corrected compressive strength was computed

using correcting factors (BIS, 2006).

Flexural strength: Flexural strength is one of the tests

performed on paver blocks which serves as a quality indicator

and it is considered as a basis for comparison in terms of wearing

resistance. Flexural strength test was performed by subjecting the

various pavers to a thwartwise force which is perpendicular to its

longitudinal axis. A center line was indicated on top of the pavers

which is perpendicular to its length. The pavers were supported

by two support rods over a span of 150mm and were tested under

a central line load until failure occurred, using the INSTRON

universal testing machine. The flexural strength values recorded

are the average of five samples each for the various paver [4].

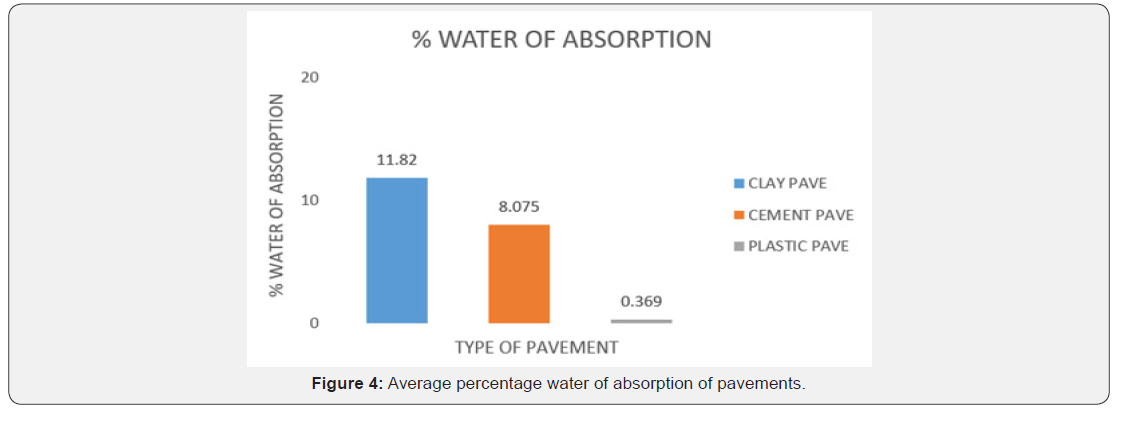

Water of absorption and durability in sea water: Water

of absorption is the determination of the rate of absorption

by measuring the increase in mass of the pavers resulting

from absorption of water over a period. The pavers were fully

immersed in a tank of fresh water for 24 hours and the weight

measured to determine the percentage of water absorption. And,

the pavements were fully immersed in a tank of sea water for four

months to determine its durability by applying a load to determine

the compressive strength using the universal testing machine. The

percent water of absorption is determined using equation (1),

Results

Density

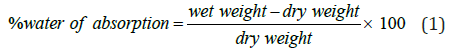

The density values of the various pavers are presented in Figure

1. The values range between 1.99g/cm3 to 2.04 g/cm3, with

fired clay pavement block having the lowest and cement pavement

block having the highest.

Compressive Strength

As shown in Figure 2 above, clay brick pavement blocks recorded

the highest compressive strength followed by the plastic

pavement blocks with the cement pavement blocks recording the

least compressive strength.

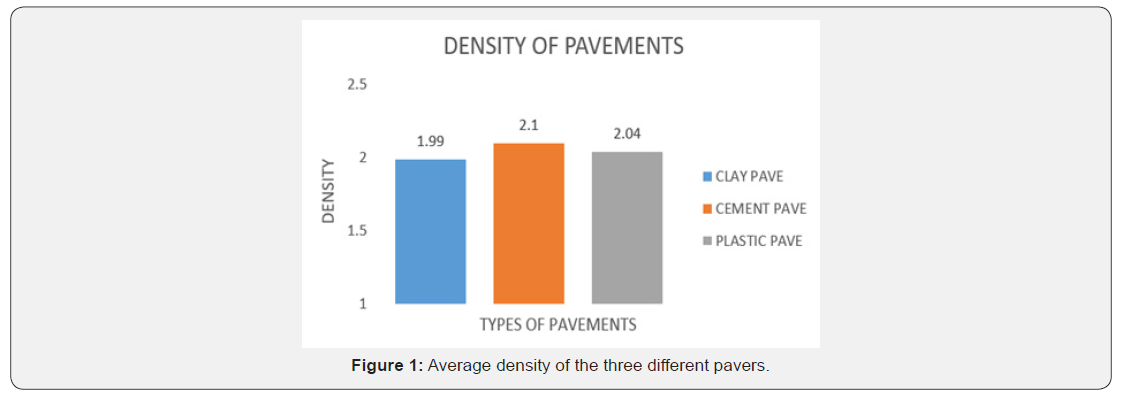

Flexural Strength

Figure 3 shows the test results of flexural strength of plastic

paver, cement paver and clay bricks to be 6.04MPa, 5.86MPa and

5.09MPa respectively.

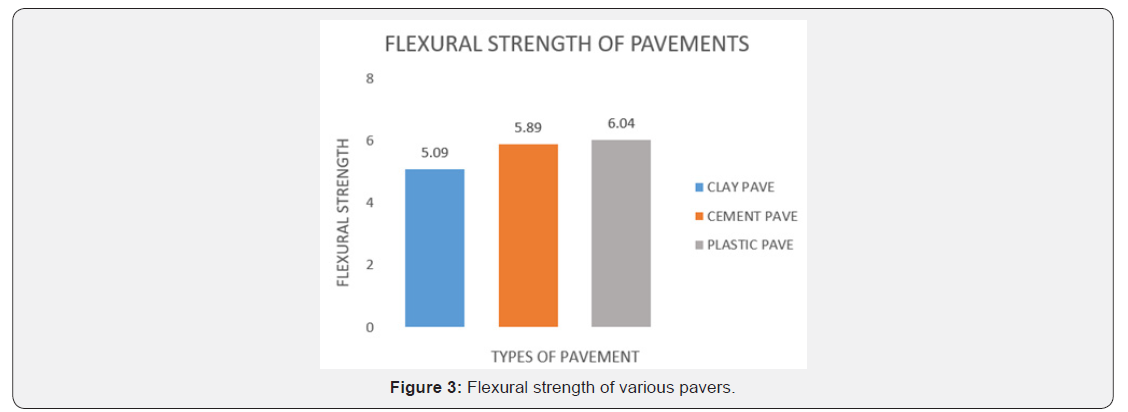

Water of Absorption

Figure 4 shows the percentage water of absorption test results

for clay bricks, cement blocks and plastic pavers as 11.82,

8.075 and 0.369 respectively

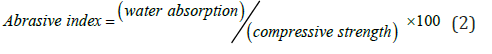

Abrasion Resistance

Abrasive resistance is a measure of the resistance of paving

brick to the wearing action due to traffic and can be calculated

using equation (2).

The maximum abrasion index for Type III i.e. pedestrian and

light traffic pavement is 0.50 and the minimum abrasion limit for

a 28day cured concrete paver is 1.20 for footpaths and car parks

(ASTM C 902-15). The three types of pavers have abrasion index

of 0.35, 0.14 and 0.014 for clay, cement and fired clay pavement

blocks respectively Figure 5.

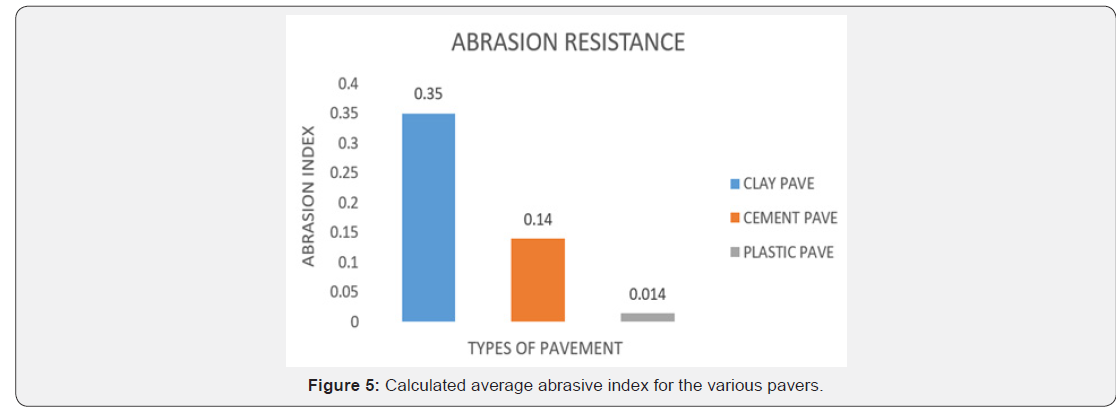

Durability in Sea water

Percentage of seawater absorbed by the three different pavement

blocks are shown in Figure 6 above.

Discussion

The density of burnt brick pavers has been stated to be between

1.826g/cm3 and 1.985g/cm3, and specific gravity of special

masonry varies between 1.20g/cm3 and 2.40g/cm3(ASTM C-902).

From the results in Figure 1, Clay pavers had the minimum density

value followed by the plastic and cement pavers of densities 2.04g/

cm3 and 2.10g/cm3 respectively. The 3 types however fall within

the standard specification. Clay pavement blocks recorded higher

average compressive strength, followed by plastic pavement

blocks and then cement pavement blocks. Clay pavement blocks

have highest thickness compared to plastic and cement pavement

blocks and this may have contributed to the high compressive

strength. Also, the compressive strength of the plastic pavement

blocks was not determined on full blocks but on a cut-out section,

may have caused a reduction in the compressive strength of

plastic pavement blocks as noted by Vila et al. [5]. The production

of clay bricks currently in Ghana relies on firewood and requires

much energy during firing. Harmful gases such CO2 may also be released

into the environment which is not eco-friendly. When firing

is not well controlled, clay bricks can develop cracks which may

lead to reduction in strength.

Cement pavers recorded the least compressive strength value

as compared to the rubberized pavers. Poor compaction is a major

factor that influence the strength of cement pavers which creates

more pores to absorb water. Secondly, decreased strength in concrete

pavers can be attributed to variation in the mix proportions

in the batching process. Improper mixing proportions and insufficient

compaction hinders the achievement of maximum density

and creates voids which contributes to reducing the strength

of the concrete pavers. Increasing void content and decreasing

density decreases the compressive of the concrete pavers [6].

Plastic pavers recorded higher compressive value than cement

pavers. Melting of plastics for plastic pavers requires less energy

since plastics have low melting points and melting is done at low

temperatures. The melting process does not release harmful gases

into the environment, and it is cheaper to produce. Therefore,

plastic pavers may be used commercially for non-traffic application.

The high flexural strength average value obtained for plastic

modified pavement block as compared to the concrete pavers

and clay bricks may be due to good adhesion of molten plastic to

the sand particles and low porosity. This is an indication that the

plastic pavement blocks could withstand higher flexural stresses

than the rest

Results obtained for water of absorption indicated that clay

brick absorbed maximum water as compared to cement paver and

plastic paver. The maximum water absorption by the clay bricks

may have occurred as a result of the presence of pores and due

to the hydrophilic nature of clay. Increased absorption of water

may result in loss of bondage of clay particles hence reduced

strength of clay pavement blocks in service. The cement pavers

absorbed less water as compared to the clay bricks. This is because

the cement creates stronger bonds between the particles,

and this minimizes the pores through which water get absorbed

by the concrete pavement block [7]. However average value obtained

for both fired clay and cement pavement blocks are more

than the minimum value of 5%. Thus, the use of these pavement blocks may not be durable especially in waterlogged areas. Water

absorption values obtained for plastic pavers are within the

specified standard of less than 5%. This may be due the low porosity

of the rubberized paver and due to the hydrophobic nature

of plastics. The water of absorption of plastic pavers have been

found to further decrease when the proportion of plastic waste is

increased. The low porosity of the plastic pavers may contribute

to little or no damage under severe conditions such as heavy rains

as compared to clay bricks and cement pavers. Clay bricks and cement

pavers may absorb water under severe condition, and this

has a tendency of weakening the bonds that exist between their

structures which may lead to formation of micro cracks. Hence

any load applied on clay bricks and cement pavers, may act on

the stress concentration points because of the presence of micro

cracks and this may cause decrease in strength. The very low

abrasion resistance value recorded by the plastic pavers indicates

that plastic pavers have high ability to withstand wearing action

than clay bricks and cement pavers which may be as a result of the

good adherence of the plastic with the sand aggregates. Seawater

durability is the ability of pavers to resist permeability of saline

solution and have improved strength to be serviceable. Four

months durability in Sea water test results are shown in Figure 4

for the various types of pavers under study.

The permeability of sea water in pavers causes two main

actions to occur; chemical reaction which usually occurs within

the pavers resulting in softening and disruptive expansion of the

pavement blocks, and crystallization of salts which occurs on the

surface of the pavers. As pavers absorb sea water, the dissolved

salts in the form of crystals are left within the joint and the pores

of the pavers which may cause expansion and increases porosity

thereby reducing the strength of pavers [8]. As indicated by

results in Figure 6, plastic pavers absorbed less Sea water. This

may be due to the low porosity exhibited and due to the structure

of plastics, i.e. strong with close intermolecular links and so this

type of pavers resists sea water [9-14] absorption as compared to

the cement and clay pavers. Therefore, plastic pavers may remain

stronger in terms of durability in high saline environment.

Conclusion

In this study clay pavement and plastic pavement blocks

obtained higher average compressive strength than the cement

pavement blocks. Durability studies suggested that plastic

pavement blocks may perform better in areas prone to flooding

and high saline content. Though the various pavement blocks

may be used for footpath, light traffic, walkway etc., the plastic

pavement blocks made from waste plastic and sand may be cheaper

and represent an alternative way of turning waste material into

useful product for a more sustained construction. Plastic waste

use as transitional material in construction is a demonstration

of how waste could be turned into a resource for cost effective,

yet a durable and sustainable material for construction. Other

advantages include minimizing plastic waste in the environment,

the landfills and water bodies contributing to cleaner cities and

towns and creation of more jobs.

To Know More About Civil Engineering Research Journal Please click on:

Very nice blog information.. Great post.

ReplyDeleteWhether you require repairs for your potholes or advice on achieving better drainage on your driveway, our staff can help improve the safety and value of your property.

Construction Companies Winnipeg

Concrete Paver Winnipeg